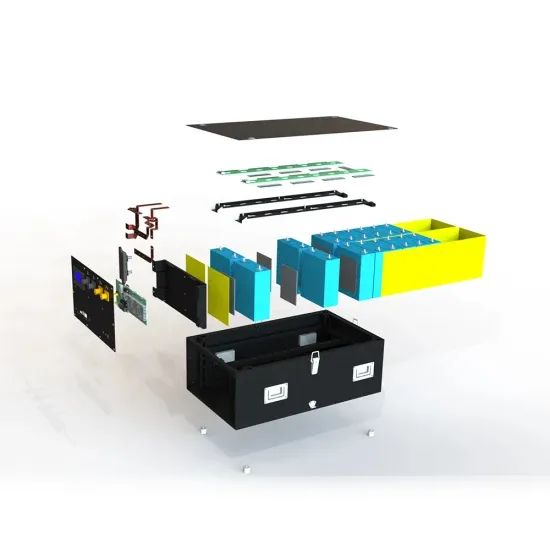

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

Jun 15, 2025 · In this step-by-step guide, I''ll walk you through the entire DIY battery pack assembly process to help you build a safe, high-performance battery.

Computer Room UPS FAQs | Server Room Evironments

Can a raised access floor support a large UPS system? Raised access floors are designed to support server racks whose weights can run up to 300Kg. In terms of a larger single or three

Battery Room Ventilation and Safety

Mar 15, 2023 · BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms

Battery cabinet installation construction process

3.2 Cabinets with separately delivered cells or block batteries: Only filled and charged cells or block batteries (vented or sealed) are built into cabinets. Assemble cabinet, place in

Install the Battery Modules in the Battery Cabinet

Install the battery modules on the shelves from top to bottom. NOTE: Pay special attention to the location of type A and type B battery modules. Reinstall the plate in front of the battery

Battery Room requirements | Eng-Tips

Dec 17, 2009 · The same data can be found in battery supplier''s O&M manuals. If the room''s ventialtion is sufficient to prevent a build up of hydrogen gas, then the area can be non

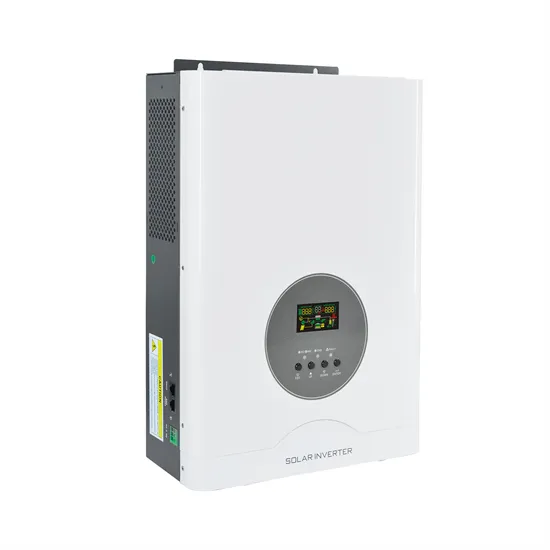

How to Install a Rack Lithium Battery System in 2025

Feb 21, 2025 · To install a rack lithium battery system, you will need the following tools and equipment: Basic Hand Tools:?Screwdrivers, wrenches, and pliers for assembly. Safety

Designing Industrial Battery Rooms: Fundamentals and

Designing Industrial Battery Rooms: Fundamentals and Standards Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Is it tiring to assemble the battery cabinet

How to install a battery storage cabinet? Mounting mechanism - they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows

Rack-Basics-White-Paper-English

Aug 9, 2025 · Racks organize IT equipment, such as servers and network switches, into standardized assemblies that make eficient use of space and other resources. Depending on

Battery Cabinet

Feb 28, 2025 · Remove watches, rings, or other metal objects. Use tools with insulated handles. Wear rubber gloves and boots. Do not lay tools or metal parts on top of batteries. Confirm that

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Assembling a lithium battery pack is a critical skill for anyone working with modern energy storage systems. Whether you''re powering an electric vehicle, a renewable energy

Battery Cabinet Battery Assembly Video Tutorial

: Outdoor Constant-temperature Battery Cabinet. Introduction: Constant-temperature Battery Cabinet is a good cabinet used for outdoor battery, with the wind, rain, sun, corrosion

How to Install a Rack Lithium Battery System in 2025

Feb 21, 2025 · Installing a rack lithium battery system is essential for ensuring reliable power supply in data centers and server rooms in 2025.? How do you install a rack lithium battery

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Securing the Cabinet to Walls or Foundations Securing the battery storage cabinet involves using appropriate methods and materials to ensure stability and safety. Begin by

6 FAQs about [How to assemble the battery cabinet in the computer room]

How do I install a battery cabinet?

Create an installation plan for the battery cabinet (Chapter 2). Prepare your site for the battery cabinet (Chapter 2). Inspect and unpack the battery cabinet (Chapter 2). Unload and install the battery cabinet, and wire the system (Chapter 3). Complete the Installation Checklist (Chapter 3).

How do I connect a ups to a battery cabinet?

Locate the UPS-to-battery cabinet breaker sensing cable inside the first battery cabinet. Mate the connector on this cable with the matching connector in the cabinet (see Drawing 164201536-8 on page A-17). Route the other end of this cable through conduit (top or bottom entry) to UPS cabinet and connect to terminal strip TB2.

How do you secure a battery cabinet?

Secure the battery cabinet position by lowering the leveling feet until cabinet is not resting on the casters. Ensure the cabinet is level and matches the height of the installed UPS cabinet. NOTE Two cabinet joining brackets are provided in the field kit for securing each cabinet at the top and bottom.

How do I install a battery cabinet breaker?

Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the matching connector in that cabinet (see Drawing 164201536-8 on page A-17). If installing multiple battery cabinets, proceed to Step 3; otherwise, proceed to Step 5.

What is a battery cabinet?

The battery cabinet is designed for industrial or computer room applications and should be handled with appropriate care. This battery cabinet contains LETHAL VOLTAGES. All repairs and service should be performed by AUTHORIZED SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE PARTS

How do I connect a battery to a ups?

Connect and route cables from positive (+) and negative (–) terminals in the bottom of the first battery cabinet into the UPS cabinet. Connect the (+) lead to terminal E4 (+) and the (–) to terminal E5 (–) in the UPS cabinet.

Learn More

- How to calculate the battery cabinet in the computer room

- How to install the battery cabinet in the computer room

- Battery cabinet price for computer room

- Installation specification requirements of battery cabinet in computer room

- Somaliland computer room battery cabinet manufacturer

- How to assemble the lithium battery station cabinet

- Battery cabinet in the computer room is open

- How much does it cost to install a battery cabinet in Port Vila

- How to check the model of lithium iron phosphate battery station cabinet

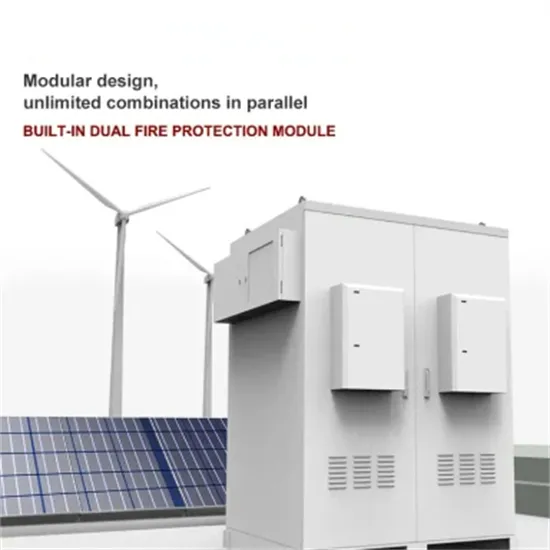

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.