Microsoft Word

Nov 15, 2017 · They also can leak potentially explosive gas (hydrogen). Never enclose batteries or battery cabinets in a sealed air tight room. All jewelry and watches must be removed prior to

BatteryRoomVentilationInstallation.PDF

Feb 19, 2004 · The battery room temperature should be between + 5° C and + 25° C. Inside the battery the maximum temperature difference between cells and blocks must not exceed 10 K

Powerware 9390 Integrated Battery Cabinet (Models IBC

Jul 16, 2023 · The Integrated Battery Cabinet (IBC) systems are housed in single free-standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

Battery Room requirements | Eng-Tips

Dec 17, 2009 · If a high voltage terminal station (in which I would expect redundant battery supplies) than it makes sense to have your batteries in a separate room. Further more the

UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Powerware 9390 Integrated Battery Cabinet (Models IBC

May 2, 2022 · During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load. The

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

Powerware 9395 Integrated Battery Cabinet (Model IBC

Jun 17, 2016 · 1 Introduction During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load.

Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · 6. SYSTEM SPECIFICATIONS 6.1 BATTERIES specific information. Type: Valve Regulated Lead Acid (VRLA), sealed, non-spilla Only cabinets with Flame Retardant Batteries

BC55 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Connects the battery cabinet to the UPS Automatically locks the battery cabinet door to prevent access to the cabinet interior during its operation as a power backup to the UPS.

Battery Cabinets Vs. Battery Racks

Jan 19, 2021 · The industrial battery cabinet shall contain batteries that can be accessed only by approved staff behind closed doors. The cabinets can also be placed in a computer room, or

Does the battery cabinet in the computer room have to be in a single room

Do battery cabinets need to be in a battery room? Because cabinets can have locked doors, the cabinets do not have to be in battery rooms; they can be installed directly adjacent to the UPS

755-00019_36inch_BATTERY_MANUAL_R01

Feb 3, 2023 · Do not open or mutilate batteries. Opened or severely damaged batteries can release toxic electrolyte which is harmful to the skin and eyes. Never lay loose cables, metal

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · Introduction Battery room compliance can be interpreted differently depending on your battery type, amount of cells or multi-cell units in a common area, volume of electrolyte

Battery Room Ventilation and Safety

Mar 15, 2023 · This course describes the hazards associated with batteries and highlights those safety features that must be taken into consideration when designing, constructing and fitting

Ventilation of spaces containing batteries 1 General

The ventilation opening for the battery room is required to be fitted with a closing device according to the Load Line Convention (i.e. the height of the opening does not extend to more than 4.5 m

How Battery Racks And Cabinets Can Help You Store Batteries

Authorised personnel must receive battery safety training, and access to the battery room must be restricted to authorised personnel. Exhaust systems must be installed in battery rooms, and

Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · Put the new battery into place. Make sure new battery is installed properly regarding polarity orie ation. Use the supplied wiring drawing found inside the battery cabinet door to ver

Problems that need to be paid attention to in the battery storage cabinet

Mar 1, 2025 · Proper ventilation is critical to avoid overheating of battery storage cabinets. Ventilation means that there should be ways for the cabinets to let in fresh air and let out hot

6 FAQs about [Battery cabinet in the computer room is open]

Do battery cabinets need to be locked?

Battery cabinets must enclose the batteries behind locked doors accessible only to authorized personnel. As long as the cabinets are kept locked, they can be located in a computer room or other rooms accessible by non-battery technicians.

Can a battery be installed in a computer room?

Sometimes they are installed in the same room as the UPS (i.e., electrical equipment room). Local or regional codes may dictate whether batteries are permitted in an electrical room. Smaller UPS systems (e.g, up to 250 kVA) are commonly installed directly in the computer room along with their respective battery cabinets.

Why do you need a battery cabinet?

Ease of use is one of the principle selling points for battery cabinets. It is convenient to service the equipment when the UPS and the battery (ies) are right next to each other. Conversely, it is inconvenient to have to go to a separate room when open-rack batteries are installed.

Can you put a battery in an electrical room?

Local or regional codes may dictate whether batteries are permitted in an electrical room. Smaller UPS systems (e.g, up to 250 kVA) are commonly installed directly in the computer room along with their respective battery cabinets. The UPS and/or battery cabinets might be configured to look like standard computer equipment racks.

Are open rack batteries dangerous?

There are two primary hazards of concern: electrical and fire. Open rack batteries expose potentially lethal voltage to any person coming in contact with them. Therefore they must be installed in battery rooms in which room access is restricted to authorized personnel only. Authorized personnel must be trained in battery safety.

Can batteries be installed in ventilated cabinets and containers?

Batteries may be installed in ventilated cabinets and containers arranged in ventilated spaces (except rooms mentioned in C.1.1) Section 2 Installation of Electrical Equipment P = U I I = 8 K/100 for Pb- batteries I = 16 K/100 for NiCd- batteries P : Charging power [W]

Learn More

- How to install the battery cabinet in the computer room

- Battery cabinet price for computer room

- How to calculate the battery cabinet in the computer room

- How to assemble the battery cabinet in the computer room

- Somaliland computer room battery cabinet manufacturer

- Can I open the battery cabinet after the UPS is turned off

- Cost of the computer room for the battery energy storage system of the communication base station

- Lisbon Outdoor Communication Battery Cabinet Warranty

- The battery cabinet is wet

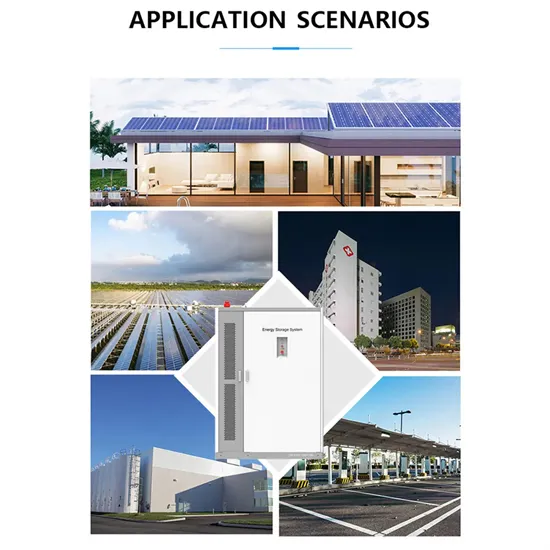

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.