Energy storage system: Current studies on batteries and power

Feb 1, 2018 · The paper summarizes the features of current and future grid energy storage battery, lists the advantages and disadvantages of different types of batteries, and points out

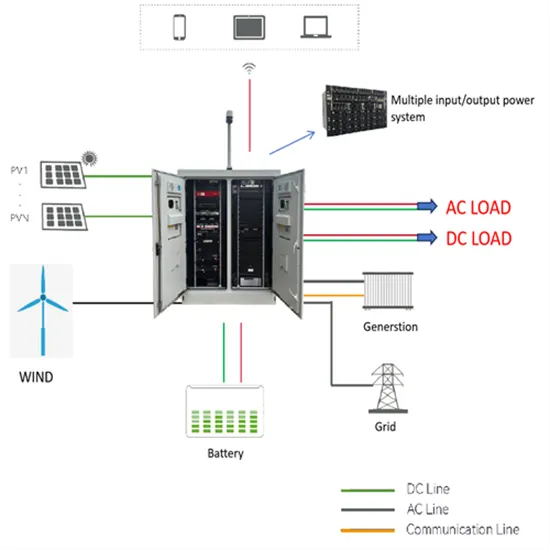

Optimised configuration of multi-energy systems

Dec 30, 2024 · This approach also results in a reduction of the total cost by ¥2.87 million. Moreover, the integration of communication base station power supply modifications and

BESS Costs Analysis: Understanding the True Costs of Battery Energy

Aug 29, 2024 · As of recent data, the average cost of a BESS is approximately $400-$600 per kWh. Here''s a simple breakdown: This estimation shows that while the battery itself is a

Cost Projections for Utility-Scale Battery Storage: 2023

Jul 25, 2023 · Executive Summary In this work we describe the development of cost and performance projections for utility-scale lithium-ion battery systems, with a focus on 4-hour

Battery energy-storage system: A review of technologies,

Oct 1, 2021 · This paper provides a comprehensive review of the battery energy-storage system concerning optimal sizing objectives, the system constraint, various optimization models, and

HANDBOOK FOR ENERGY STORAGE SYSTEMS

Singapore has limited renewable energy options, and solar remains Singapore''s most viable clean energy source. However, it is intermittent by nature and its output is affected by environmental

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Energy storage cost – analysis and key factors to

4 days ago · This article provides an analysis of energy storage cost and key factors to consider. It discusses the importance of energy storage costs in the

A review of battery energy storage systems and advanced battery

May 1, 2024 · This article provides an overview of the many electrochemical energy storage systems now in use, such as lithium-ion batteries, lead acid batteries, nickel-cadmium

Utility-Scale Battery Storage | Electricity | 2024 | ATB | NREL

The battery storage technologies do not calculate levelized cost of energy (LCOE) or levelized cost of storage (LCOS) and so do not use financial assumptions. Therefore, all parameters are

Grid-connected battery energy storage system: a review on

Aug 1, 2023 · Battery energy storage system (BESS) has been applied extensively to provide grid services such as frequency regulation, voltage support, energy arbitrage, etc. Advanced

Comparative techno-economic evaluation of energy storage

Jun 1, 2024 · Energy storage technology is a crucial means of addressing the increasing demand for flexibility and renewable energy consumption capacity in power systems. This article

DOE ESHB Chapter 25: Energy Storage System Pricing

Sep 3, 2021 · This chapter summarizes energy storage capital costs that were obtained from industry pricing surveys. The survey methodology breaks down the cost of an energy storage

Optimal Location and Sizing of Battery Energy Storage System

Dec 10, 2021 · This paper proposes a methodology to determine the optimal location and sizing of a battery-based energy storage system in order to minimize generation cost in

Optimal configuration of 5G base station energy storage

Mar 17, 2022 · Abstract: The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize

Communication for battery energy storage systems

Dec 1, 2018 · This paper examines the development and implementation of a communication structure for battery energy storage systems based on the standard IEC 61850

Operating costs of battery energy storage

Xue et al. (2016) framed a general life cycle cost model to holistically calculate various costs of consumer-side energy storage, the results of which showed the average annual cost of battery

Cost-based site and capacity optimization of multi-energy storage

Dec 15, 2022 · The unbalance between the renewable energy sources and user loads reduces the performance improvement of regional integrated energy systems (RIES), in which the multi

6 FAQs about [Cost of the computer room for the battery energy storage system of the communication base station]

What is a battery energy storage system (BESS) model?

Tailored to the specific requirement of setting up a Battery Energy Storage System (BESS) plant in Texas, United States, the model highlights key cost drivers and forecasts profitability, considering market trends, inflation, and potential fluctuations in raw material prices.

Are battery energy storage systems worth the cost?

Battery Energy Storage Systems (BESS) are becoming essential in the shift towards renewable energy, providing solutions for grid stability, energy management, and power quality. However, understanding the costs associated with BESS is critical for anyone considering this technology, whether for a home, business, or utility scale.

How much does a commercial energy storage system cost?

The cost of commercial energy storage depends on factors such as the type of battery technology used, the size of the installation, and location. On average, lithium-ion batteries cost around $132 per kWh. 3. What are the ongoing costs of energy storage systems?

What is the financial model for the battery energy storage system?

Our financial model for the Battery Energy Storage System (BESS) plant was meticulously designed to meet the client’s objectives. It provided a thorough analysis of production costs, including raw materials, manufacturing processes, capital expenditure, and operational expenses.

How profitable is battery energy storage system (BESS)?

Profitability Analysis Year on Year Basis: The proposed Battery Energy Storage System (BESS) plant, with an annual installed capacity of 1 GWh per year, achieved an impressive revenue of US$ 192.50 million in its first year.

What are energy storage costs?

When considering energy storage costs, it’s crucial to take both capital expenditure (CAPEX) and operational expenditure (OPEX) into account. CAPEX includes the cost of the battery system itself, installation, permits, and other infrastructure needed for the system’s operation.

Learn More

- How much does a flywheel energy storage room for a communication base station cost

- Battery energy storage system power generation in the communication base station room

- What qualifications are required for communication base station battery energy storage systems

- Whose battery energy storage system is Kathmandu s communication base station

- Buenos Aires Communication Base Station Battery Energy Storage System Construction and Development

- 2MWH Communication Base Station Battery Energy Storage System Power Generation Company

- Algiers communication base station flow battery energy storage

- Nouakchott communication base station backup energy storage battery

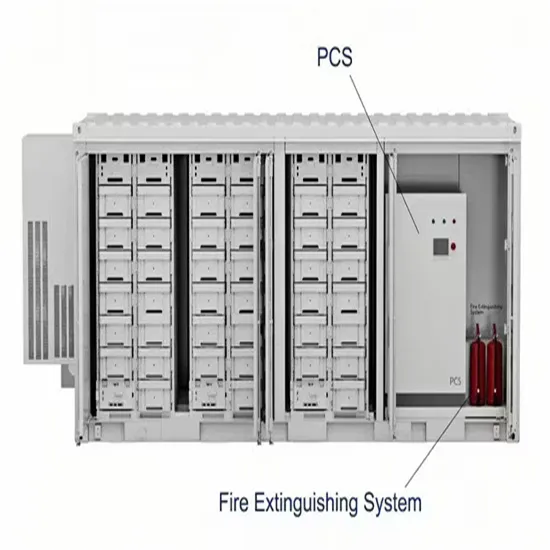

- Fire extinguishing scheme design for battery energy storage system of communication base station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.