Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · Cabinet Installation, Operation, & Maintenance Manual Built for Mitsubishi Electric Power Products, Inc. by This manual contains proprietary and confidential information of C&C

Guidelines for storage & usAGE of lead acid batteries

May 19, 2022 · 1 Battery Overview There are primarily three kinds of batteries used in UPSs—vented lead acid (VLA) (also called flooded-cell),valve-regulated lead-acid (VRLA),

Ventilation and Cooling Requirements for ICT rooms

Nov 5, 2020 · Ensure that ice water production for ICT rooms is independent of production for the remainder of the building, and that the temperature of the ice water is suited to the needs of

A Guide To UPS Room Layout | Carter Sullivan

May 4, 2020 · We explore the fundamentals of UPS room layout and the things you need to consider when deciding where to locate your essential power protection systems.

Ventilation/Air-conditioning system for battery room | Eng

Aug 25, 2006 · hello, I just found this site helpful and I hope you guys can help me too. I am not familiar with the air-conditioning system and exhaust fans. There''s a battery room that will be

Energy Storage Battery Cabinet Installation: Your Roadmap

Mar 23, 2025 · Let''s face it – energy storage battery cabinets aren''t exactly the Beyoncé of renewable energy systems. But just like backup dancers, they''re critical to the show. A poorly

Battery Room Ventilation and Safety

Mar 15, 2023 · BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms

How to Build a Battery Room for Lithium-ion,

Jun 24, 2025 · Build a safe, efficient battery room for lead-acid, lithium-ion & EV batteries. Learn layout, ventilation & charging tips to maximise safety &

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · Connect the power system''s battery cable terminated in an Anderson connector to the first battery cabinet''s battery cable terminated in a mating Anderson connector.

PDU8000 Battery Cabinet-T Quick Guide (02405680)

Nov 1, 2019 · 2. Cabinet dimensions (H x W x D): 2000 mm × 600 mm × 1100 mm (Single Cabinet) Only trained and qualified personnel are allowed to install, operate, and maintain

How to Manage a Safe Battery Storage Room | Impact Battery

Oct 10, 2012 · The heating, cooling and ventilation systems for the battery room should be checked to ensure that they are working properly. If the inspection determines that the battery

How to Install and Maintain a Server Rack Battery Backup?

Mar 11, 2025 · To install and maintain a server rack battery backup, select a compatible rackmount UPS, securely mount it in your server rack, connect your equipment, and configure

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Discover the components and benefits of battery storage cabinet systems, including lithium-ion advantages, placement considerations, ventilation needs, and cost

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the

UPS Battery Cabinets | Information by Electrical Professionals

Feb 7, 2024 · The batteries are factory installed in the cabinets and connected by jumpers between the cabinets. Depending on the battery size the cabinets can weigh up to 5000

Position and Interconnect the Battery Cabinets

Install the ten interconnection screws (five in the front and five in the rear) between the two battery cabinets. NOTE: To reach the five interconnection screws in the rear of the left-most battery

UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Install the main POS and NEG cables from the output circuit breaker to the correct battery posts on the designated battery units shown in the provided battery system schematic.

How to Install a Home Battery Backup System: A Step-by

Jan 20, 2025 · Learn how to install a home battery backup system with this easy-to-follow, step-by-step guide. Ensure reliable power during outages with our expert tips on installation,

Designing Industrial Battery Rooms: Fundamentals and

Designing Industrial Battery Rooms: Fundamentals and Standards Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article

How to correctly install lithium battery energy

Mar 25, 2024 · Lithium battery energy storage cabinets can meet the needs of different large-scale projects and are very suitable for grid auxiliary services

How to Install a Rack Lithium Battery System in 2025

Feb 21, 2025 · Installing a rack lithium battery system is essential for ensuring reliable power supply in data centers and server rooms in 2025.? How do you install a rack lithium battery

BC55 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Connects the battery cabinet to the UPS Automatically locks the battery cabinet door to prevent access to the cabinet interior during its operation as a power backup to the UPS.

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Battery Room requirements | Eng-Tips

Dec 17, 2009 · The same data can be found in battery supplier''s O&M manuals. If the room''s ventialtion is sufficient to prevent a build up of hydrogen gas, then the area can be non

6 FAQs about [How to install the battery cabinet in the computer room]

How do I connect a battery cabinet to a power system?

Procedure 1. Furnished with the battery cabinet are battery disconnect circuit breaker alarm lead assemblies. Refer to the power system installation manual to use these alarm leads to connect the battery cabinet battery disconnect circuit breaker alarm into the power system alarm circuits.

How do I connect a ups to a battery cabinet?

Locate the UPS-to-battery cabinet breaker sensing cable inside the first battery cabinet. Mate the connector on this cable with the matching connector in the cabinet (see Drawing 164201536-8 on page A-17). Route the other end of this cable through conduit (top or bottom entry) to UPS cabinet and connect to terminal strip TB2.

How do I install a battery cabinet breaker?

Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the matching connector in that cabinet (see Drawing 164201536-8 on page A-17). If installing multiple battery cabinets, proceed to Step 3; otherwise, proceed to Step 5.

How do you secure a battery cabinet?

Secure the battery cabinet position by lowering the leveling feet until cabinet is not resting on the casters. Ensure the cabinet is level and matches the height of the installed UPS cabinet. NOTE Two cabinet joining brackets are provided in the field kit for securing each cabinet at the top and bottom.

How do you reinstall a battery cabinet?

Reinstall the left side panel on the left-most battery cabinet after interconnection. Push the third battery cabinet into position, align with the seismic anchoring (if any), level the battery cabinet, and interconnect with the other battery cabinets as described in step 2, step 3, and step 5.

How do I install a VDC battery cabinet?

Set first battery in cabinet and attach the long lead (fast-on connector side marked positive) from the cabinet to the fast-on terminal on the positive terminal of the battery. See Figure 24. Facing left Facing right Facing left Vertiv™ NetSure™ 211 SERIES -48 VDC Battery Cabinet Installation & User Manual (Section 6023) Rev. L 23 Figure 24:

Learn More

- How to assemble the battery cabinet in the computer room

- How to calculate the battery cabinet in the computer room

- How to install the crossbeam of the battery cabinet

- How to install the battery cabinet of the signal tower

- Battery cabinet price for computer room

- How much does it cost to install a battery cabinet in Northern Cyprus

- Somaliland computer room battery cabinet manufacturer

- Battery cabinet in the computer room is open

- Battery cabinet lithium battery charging cabinet how much

Industrial & Commercial Energy Storage Market Growth

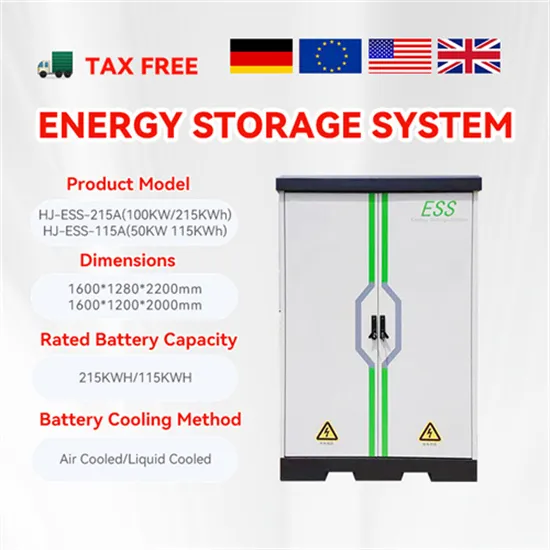

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.