How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Securing the battery storage cabinet involves using appropriate methods and materials to ensure stability and safety. Begin by selecting the correct fasteners for your wall or

Powerware 9390 Integrated Battery Cabinet (Models IBC

May 2, 2022 · During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load. The

Installation Guide: Crossbeam for Salesforce (Connector Plan)

Connector plan users do not have access to data in the Crossbeam Custom Object. However, the object is still installed as part of the managed package. No data is pushed to it for Connector

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

Installing Power Supply and Distribution Devices

When installing batteries, install battery trays at first, then place batteries onto the trays, and connect cables. Do not move all the batteries into the cabinet after placing the batteries on the

电池安装桁架工装快速指南 Battery Installation Truss

Oct 10, 2024 · 10. 将托盘升高到要更换的电池包轨道高度,安装托盘固定螺栓(以更换第6层电池包为例)。 Raise the tray to the rail height of the battery pack to be replaced, and then install bolts

/15/20KVA UPS Battery Cabinet Installation and

Jan 9, 2025 · SAVE THESE INSTRUCTIONS This manual contains important safety instructions. Read all safety, installation and operating instructions before installing the Battery Bank. This

Galaxy Lithium-ion Battery Cabinet

Jan 2, 2025 · Read these instructions carefully and look at the equipment to become familiar with it before trying to install, operate, service or maintain it. The following safety messages may

Install the Battery Modules in the Battery Cabinet

Install the battery modules on the shelves from top to bottom. NOTE: Pay special attention to the location of type A and type B battery modules. Reinstall the plate in front of the battery

Eaton 93E External Battery Cabinet installation manual

Sep 23, 2024 · The Eaton® External Battery Cabinet (EBC) provides extended emergency short-term backup power for the 93E 20-30 kVA and 40-60 kVA UPS to enhance the usability and

Installation Guide: Crossbeam for Salesforce (v2)

Use this guide to understand how to install and configure the Crossbeam managed package for Salesforce, which includes "Crossbeam Copilot" (a Lightning Web Component) and

Position and Interconnect the Battery Cabinets

Install the ten interconnection screws (five in the front and five in the rear) between the two battery cabinets. NOTE: To reach the five interconnection screws in the rear of the left-most battery

Eaton EBC Installation and Operation Manual

Sep 2, 2024 · Chapter 1 Introduction The Eaton® External Battery Cabinet (EBC) provides extended emergency short-term backup power for the 93E 80-200 kVA, 93E 300–400 kVA

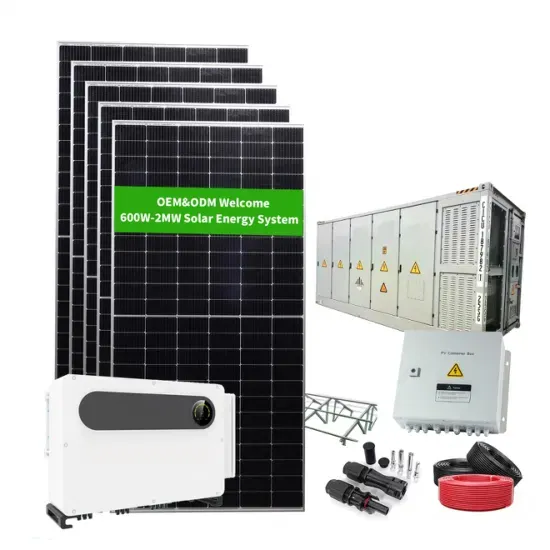

How to correctly install lithium battery energy

Mar 25, 2024 · Lithium battery energy storage cabinets can meet the needs of different large-scale projects and are very suitable for grid auxiliary services

USER''S AND INSTALLATION GUIDE

Jul 2, 2025 · Battery cabinet internal power wiring, Battery-to-UPS power wiring and control wiring for integral line-up and match battery cabinets are supplied with both the small and large

Battery Cabinet

Feb 28, 2025 · Install the Battery Cabinet following local building requirements and applicable codes. Plan the location of the Battery Cabinet site ahead of time, taking into consideration the

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

6 FAQs about [How to install the crossbeam of the battery cabinet]

How do I install a battery cabinet?

Create an installation plan for the battery cabinet (Chapter 2). Prepare your site for the battery cabinet (Chapter 2). Inspect and unpack the battery cabinet (Chapter 2). Unload and install the battery cabinet, and wire the system (Chapter 3). Complete the Installation Checklist (Chapter 3).

How do you secure a battery cabinet?

Secure the battery cabinet position by lowering the leveling feet until cabinet is not resting on the casters. Ensure the cabinet is level and matches the height of the installed UPS cabinet. NOTE Two cabinet joining brackets are provided in the field kit for securing each cabinet at the top and bottom.

How do you attach a battery cabinet to a field kit?

A flat bracket joins the top of the cabinets and a larger flat bracket joins the cabinets at the bottom. The small flat bracket is attached to the cabinet tops first. Remove the left‐hand and right-hand screws from the adjacent top door hinges of the battery cabinets. Locate the small flat bracket from the field kit.

How do I install a battery cabinet breaker?

Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the matching connector in that cabinet (see Drawing 164201536-8 on page A-17). If installing multiple battery cabinets, proceed to Step 3; otherwise, proceed to Step 5.

What are the battery cabinet external wiring requirements?

The battery cabinet external wiring requirements are shown in Tables D and E. NOTE 1:1All specified wire sizes are 90 C rated copper minimum. NOTE 2:Replace with same type and number of original battery. Mixing battery letter designation and or sizes will damage equipment and void warranty.

How do I connect a ups to a battery cabinet?

Locate the UPS-to-battery cabinet breaker sensing cable inside the first battery cabinet. Mate the connector on this cable with the matching connector in the cabinet (see Drawing 164201536-8 on page A-17). Route the other end of this cable through conduit (top or bottom entry) to UPS cabinet and connect to terminal strip TB2.

Learn More

- How to install the battery cabinet of the signal tower

- How to install lithium iron phosphate battery station cabinet

- How to install an outdoor rainproof battery cabinet

- How to install the battery cabinet in the computer room

- How much is the appropriate cost for battery cabinet installation

- How much does it cost to replace the battery cabinet for photovoltaic communication

- How to discharge the battery in the battery cabinet

- How big a battery can be placed in the a32 battery cabinet

- How far is the battery cabinet from the wall

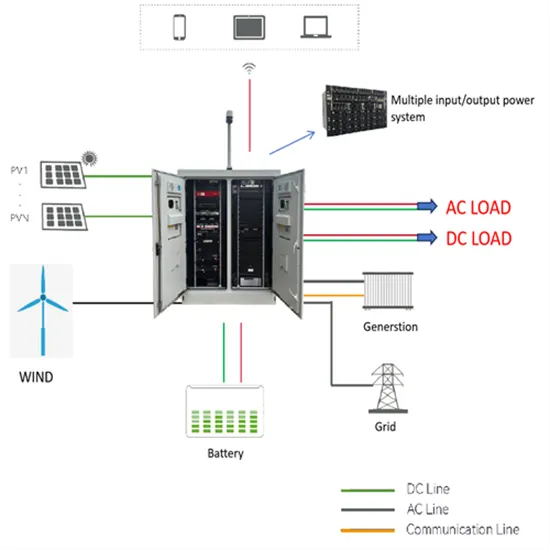

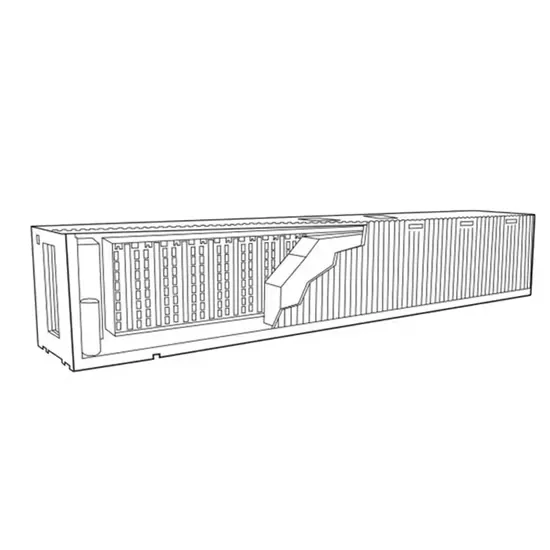

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.