Wall-Mounted Battery Installation: Avoid These 5 Mistakes

May 6, 2025 · Avoid these 5 critical mistakes in Wall-Mounted Battery Installation! Learn pro tips for safe setups, 30% longer lifespan, and compliance with UL/IEC standards.

Finding the Perfect Distance: How Far Should a Fridge Be Off the Wall

Dec 9, 2024 · Additionally, providing the necessary distance helps prevent wear and tear on the fridge''s components, thereby extending its lifespan. Why does the distance from the wall

How much space should be between base cabinets and wall cabinets?

How much space is needed between cabinets? 42" is nice, but 36" is minimum passing and still works perfectly functionally. Do base cabinets go against the wall? Leave a space between the

Kitchen Cabinet Space: Making The Most Of Your Walls

Feb 13, 2025 · Get the most out of your kitchen walls with these clever storage solutions. Learn how to utilize wall space to create functional and stylish kitchen cabinets.

6 Battery Energy Storage Systems — Lithium | UpCodes

The BESS-Li cabinets or open battery racks must be separated from other BESS-Li cabinets or open battery racks by a minimum of 3 feet (1 m) or by partitions extending from floor to

Work Space about battery racks | Information by Electrical

May 11, 2011 · My question is on the interpetation the work space about a battery system. The passage below is out of the 2011 NEC. My question is the requirment for work space. We

The Depth Of Kitchen Cabinets: How Far Do They Come Out?

Feb 13, 2025 · The width of wall cabinets usually ranges from 12 to 36 inches. Tall cabinets, also referred to as pantry or utility cabinets, are the tallest of the three types. They often serve as

Fire Alarm Panel and External Battery Distance/Location

Oct 28, 2021 · The closest Siemens comes is saying you should align the knockouts in the top of the battery cabinet with those in the bottom of the fire alarm control unit. I know at a power

Recessed Lights: Optimal Distance From Kitchen Cabinets

Feb 17, 2025 · Learn the optimal distance for recessed lights from your kitchen cabinets to achieve the perfect balance of task lighting and ambiance without compromising your design

How far should kitchen cabinets be from the ceiling?

Nov 2, 2023 · How far down from ceiling should kitchen cabinets be? Most homes built in the last 50 years have kitchen cabinets that are 32 or 36 inches tall, installed so there is a gap of 1 to 2

Best Practices and Considerations for Siting Battery

Aug 23, 2024 · Is there available space to install the battery storage system? • If the battery storage system will be located indoors, it is important to confirm that there will be suficient

How far from inverter can batteries be?

Feb 6, 2023 · You''ll lose 20% of the battery capacity, but the lifetime will be substantially increased, and the BMS won''t have to do very much to protect the battery. Another

Optimal Height For Hanging Kitchen Cabinets From Ceiling

Feb 13, 2025 · The optimal height for hanging kitchen cabinets is crucial for functionality and aesthetics. Learn the standard measurements, and explore tips for customizing cabinet height

Wall-Mounted Battery Installation: Avoid These 5 Mistakes

May 6, 2025 · Based on industrial standards and real-world failure cases, here are the top 5 installation mistakes—and proven fixes to ensure safety and maximize ROI. A typical 5kWh

What is the appropriate safety distance between battery

measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wa

Kitchen Cabinet Entry Ways: How Far Is Too Far? | ShunShelter

Feb 13, 2025 · Kitchen cabinet entry ways are a key design feature. Explore the options and find out how far is too far when it comes to this important design choice.

How close can a cabinet be to a wall?

Jul 26, 2025 · In many cases, each cabinet will be slightly different and require different spacing from a wall to avoid potential issues with the cabinet and wall over time. Do base cabinets go

Thinking About A Home Battery? Better Think

Oct 24, 2022 · The Australian Standard for home battery installations is quite strict about where solar batteries can and can''t go. The best place to install a

How much space should be between upper cabinets and

Oct 3, 2023 · Which way should upper cabinets open? Set up Cabinet Doors in Pairs The doors open in opposite directions like the pages of a book. If you have a mounted microwave above

6 FAQs about [How far is the battery cabinet from the wall ]

How much space do you need for a battery system?

Spaces about battery systems shall comply with 110.26. Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance.

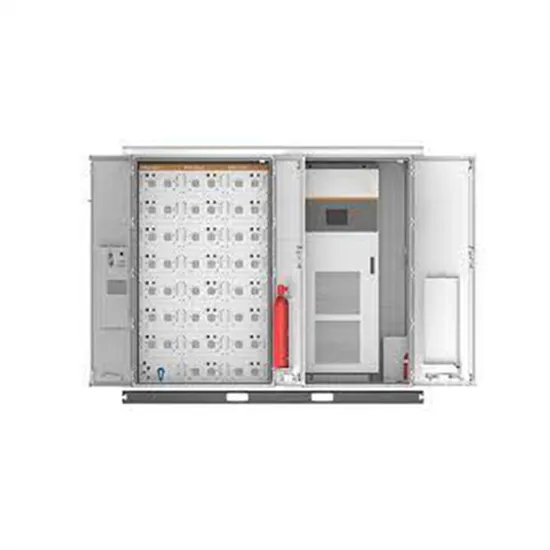

Where should a battery cabinet be installed?

The battery cabinet must be installed adjacent to the power cabinet. The following diagram shows the equipment layout for a typical new indoor Macrocell site. Notes: The cabinets may be placed with zero clearance to the rear wall. The cabinets may be placed with zero clearance to the side wall, however some clearance is recommended.

What is the minimum clearance for a battery rack?

For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance. Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length.

How far away should a cabinet be from the wall?

For example, if one wall tips in 1/4 in., you’ll need to hold the top of the base cabinet about 1/8 in. away from the wall so that the upper wall cabinet can be tight against the wall. This will all make sense once you start drawing the exact cabinet dimensions on the wall (see Photo 3).

Can a battery stand contact a wall?

Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length. (D) Top Terminal Batteries.

What is the minimum space between ezbfi frame and UMTS macrocell cabinet?

Minimum space between the EZBFi frame and the adjacent cabinet or frame is 57 mm (2.24 in.) (if the edge of the template is cut at the dotted line). The following diagram shows the clearance requirements for the indoor UMTS Macrocell cabinet from the top of the cabinet to the cable rack and from the top of the cable rack to the ceiling.

Learn More

- How much is the price of outdoor communication battery cabinet in the Netherlands

- How big a battery can be placed in the a32 battery cabinet

- How to discharge the battery in the battery cabinet

- How to check the model of lithium iron phosphate battery station cabinet

- How to charge the smart rechargeable battery cabinet

- How much is the appropriate cost for battery cabinet installation

- How much does it cost to install a battery cabinet in Northern Cyprus

- How much current does the battery cabinet have

- How far is the distance of communication base station battery power generation

Industrial & Commercial Energy Storage Market Growth

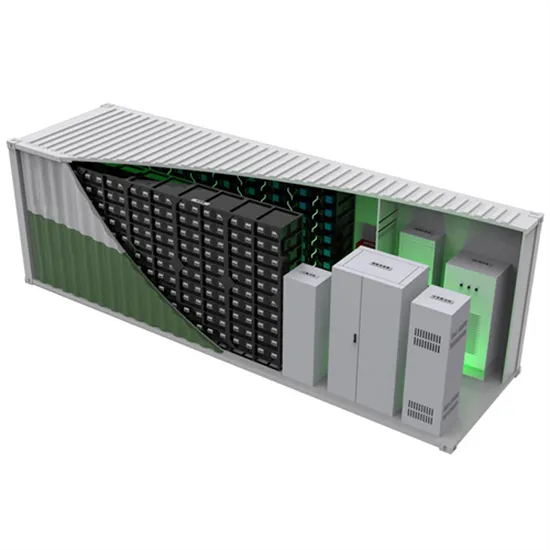

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.