UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · 6.2.1 EQUIPMENT LOCATION Prior to installation, verify floor loading requirements and all applicable codes pertaining to the related equipment. Environmental conditions should

Stationary Storage Battery Systems | UpCodes

The following information shall be provided with the permit application: Location and layout diagram of the room in which the stationary storage battery system is to be installed. Details

BC55 Battery Cabinet Installation, Operation,

Feb 3, 2025 · 6.2.1 EQUIPMENT LOCATION Prior to installation, verify floor loading requirements and all applicable codes pertaining to the related equipment. Environmental conditions should

UPS/DC Battery Room, Equipment Installation Requirements

Cabinets or racks shall be provided in the battery room for storing maintenance tools and safety equipment. These cabinets and racks shall be acid or alkaline resistant as applicable. Battery

Considerations For Battery Room Design, Battery Stands and

This article looks at the preferred designs for battery rooms and discusses how batteries should be laid out to give a safe environment. Alternative battery stand types are discussed to

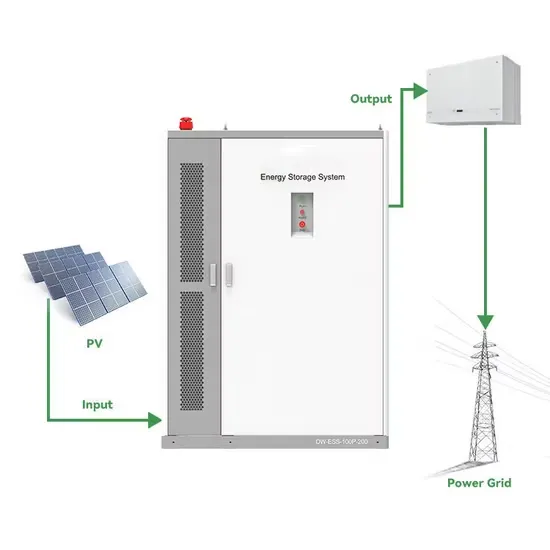

Design specification of energy storage cabinet in

Outdoor energy storage cabinet, with standard configuration of 30 kW/90 kWh, is composed of battery cabinet and electrical cabinet. It can apply to demand regulation and peak shifting and

General Battery Facility Specification Guide 10

Jan 20, 2025 · Dry room & cleanroom system permeability needs to be suitable for battery manufacturing. Eliminate or control water vapour leakages. Specifically designed for

A Guide To UPS Room Layout | Carter Sullivan

May 4, 2020 · We explore the fundamentals of UPS room layout and the things you need to consider when deciding where to locate your essential power protection systems.

BC55 Battery Cabinet Installation, Operation,

Feb 3, 2025 · re: See battery specifications for optimal operating temperatures. Ventilation: Ventil tion holes are located in the front, rear, and top of the cabinet. Clearance around the

Battery Energy Storage System Installation requirements

Mar 16, 2021 · This standard places restrictions on where a battery energy storage system (BESS) can be located and places restrictions on other equipment located in close proximity to

UPS/DC Battery Room, Equipment Installation Requirements

QC Before Installation – Battery room Equipment shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of work. Incoming Battery

GUIDE TO INSTALLING A HOUSEHOLD BATTERY

Nov 7, 2019 · WHY INVEST IN A HOUSEHOLD BATTERY STORAGE SYSTEM? Battery storage allows you to store electricity generated by solar panels during the day for use later, like at

BatteryRoomVentilationInstallation.PDF

Feb 19, 2004 · The battery room temperature should be between + 5° C and + 25° C. Inside the battery the maximum temperature difference between cells and blocks must not exceed 10 K

Battery cabinet setting specification national standard

The CyberPower BCT3L9N125 3-Phase Modular UPS Battery Cabinet can hold up to 6 battery modules (BM120V30ATY). These 3-layer units can be configured as stand-alone cabinets,

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

Guidelines for storage & usAGE of lead acid batteries

May 19, 2022 · 1 Battery Overview There are primarily three kinds of batteries used in UPSs—vented lead acid (VLA) (also called flooded-cell),valve-regulated lead-acid (VRLA),

Specifications and requirements for fire protection

In layman''s terms,a standard provides minimum requirements and/or instructions in agreement within the industry for common reference. Common standards in the battery room include

6 FAQs about [Installation specification requirements of battery cabinet in computer room]

What are the battery cabinet external wiring requirements?

The battery cabinet external wiring requirements are shown in Tables D and E. NOTE 1:1All specified wire sizes are 90 C rated copper minimum. NOTE 2:Replace with same type and number of original battery. Mixing battery letter designation and or sizes will damage equipment and void warranty.

What are the requirements for a battery room?

Battery room walls and floor shall be made of concrete construction. Battery rooms shall be provided with enclosed and gasketed (i.e., vapor tight) corrosion resistant lighting fixtures as specified in SAES-P-123. Battery room lighting shall be installed to provide a minimum level of illumination of 30-ft candles (300 lux).

What are the requirements for a battery room ventilation system?

The ventilation system is determined such that the hydrogen concentration shall be limited to less than 1% of the total air volume of the battery room. Audible and visual alarm shall be installed outside the battery room entrance to annunciate a failure in ventilation for immediate action.

What should be included in a battery room?

Cabinets or racks shall be provided in the battery room for storing maintenance tools and safety equipment. These cabinets and racks shall be acid or alkaline resistant as applicable. Battery rooms shall be vented to the outside air by forced ventilation to prevent accumulation of hydrogen and to maintain design temperature.

How do I install a battery cabinet?

Create an installation plan for the battery cabinet (Chapter 2). Prepare your site for the battery cabinet (Chapter 2). Inspect and unpack the battery cabinet (Chapter 2). Unload and install the battery cabinet, and wire the system (Chapter 3). Complete the Installation Checklist (Chapter 3).

What is a battery cabinet?

The battery cabinet is designed for industrial or computer room applications and should be handled with appropriate care. This battery cabinet contains LETHAL VOLTAGES. All repairs and service should be performed by AUTHORIZED SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE PARTS

Learn More

- Minimum load bearing capacity of battery cabinet in computer room

- Battery cabinet in the computer room is open

- How to calculate the battery cabinet in the computer room

- Somaliland computer room battery cabinet manufacturer

- DC battery cabinet grounding requirements and standards

- Lithium Battery Site Cabinet Requirements

- How much is the appropriate cost for battery cabinet installation

- Outdoor photovoltaic communication battery cabinet installation

- Cost of the computer room for the battery energy storage system of the communication base station

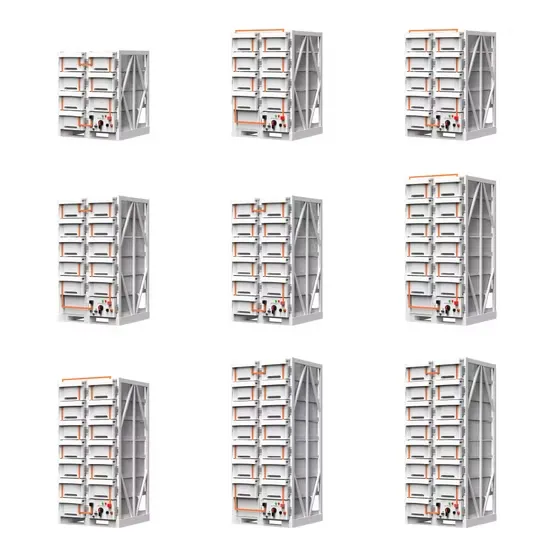

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.