Load-bearing standard and load-bearing calculation method of computer room

When designed into a computer room, if you want to meet the room specifications, you should consider doing a loose load-bearing bracket under the cabinet, the bottom of the bearing

Stationary Storage Battery Systems | UpCodes

Fires or explosions will be contained within unoccupied battery storage rooms for the minimum duration of the fire-resistance -rated walls identified in Table 509. Fires and explosions in

Dynamic mechanical behaviors of load-bearing battery

Sep 1, 2024 · To better illustrate the performance of the integrated load-bearing battery structures and facilitate lightweight design, two additional constructions were designed for comparison:

Specifications and requirements for battery cabinets in

o Battery rack/cabinet (if battery modules or Pre-assembled battery system requires external battery racks/cabinets for mechanical mounting/protection). o Balance of system components

Data center design standards for cabinet and floor loading

Jun 29, 2011 · So the average maximum floor loading from those cabinets was actually more like 70-80 PSF, depending on aisle width. Most office floors can support that. If you increase the

Do Lithium Ion Batteries Require A Battery Room? Storage

Apr 16, 2025 · Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements.

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · Introduction Battery room compliance can be interpreted differently depending on your battery type, amount of cells or multi-cell units in a common area, volume of electrolyte

Designing Industrial Battery Rooms: Fundamentals and

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards. 1. Space

Methods for insufficient load-bearing capacity of machine room

For buildings used for machine rooms or record room, there are special requirements for floor loadings, such as higher load design values than ordinary office buildings. Therefore, it is

Basics of Load Calculations in Structural Design

May 21, 2022 · Perhaps the first thing for the Structural Engineers to be aware of in their structural design is the assumptions and consideration of the design

Practical considerations when designing a battery room

Jul 27, 2018 · Minimum dimensions: Depending on the type of rack or cabinet chosen (https://goo.gl/1wUk3B - Practical considerations for choosing racks – Sizing examples), there

Data Center Raised Floor Loading Calculation: Weight Capacity

Understanding the load-bearing capacity and load standards of the data center raised floor is crucial to ensuring the safe and reliable operation of the data center.

Requisite minimum load | SKF

In applications where the bearing size is determined by factors other than load – for example, shaft diameter constrained by critical speed – the bearing may be lightly loaded in relation to

6 FAQs about [Minimum load bearing capacity of battery cabinet in computer room]

How many LBS can a cabinet support?

Wider, deeper cabinets can enable us to support 1,500-pound cabinets on standard office floors, and 2,000-pound cabinets on the stronger floors found in some buildings, but beyond that we still need structural help. Some operations have chosen abnormally tall cabinets that save floor space (48U-52U instead of the standard 42U).

What are the requirements for a battery layout?

The layout should accommodate: 2. Structural Requirements Floor loading capacity is critical - industrial batteries typically weigh 1500-3000 kg/m². For VLA (flooded) batteries, acid-resistant floor coatings compliant with AS/NZS 2430.3.2 are required.

What standards are used in a battery room?

Common standards in the battery room include those from American Society of Testing Materials (ASTM) and Institute of Electrical and Electronic Engineers (IEEE). Model codes are standards developed by committees with the intent to be adopted by states and local jurisdictions.

What are the requirements for a battery installation?

1. Space Planning and Layout 900mm min Battery Room Layout 1200mm Primary Access End Access 1000mm Battery Racks Industrial battery installations require adequate spacing for maintenance, ventilation, and safety. The layout should accommodate: 2. Structural Requirements

What is suspended load-bearing capacity?

Suspended Load-Bearing Capacity Suspended load-bearing capacity refers to the load that the structure beneath the floor can support, which is particularly important for supporting heavy cable trays and other equipment. Application of Raised Floor Load Standards in Data Center

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

Learn More

- How to calculate the battery cabinet in the computer room

- Installation specification requirements of battery cabinet in computer room

- Somaliland computer room battery cabinet manufacturer

- Battery cabinet in the computer room is open

- Battery cabinet price for computer room

- Battery cabinet and load cell

- How to calculate the battery capacity of the energy storage cabinet

- Telecom Energy Storage Clean Energy Storage Cabinet Battery Capacity

- Philippines large capacity battery cabinet manufacturer

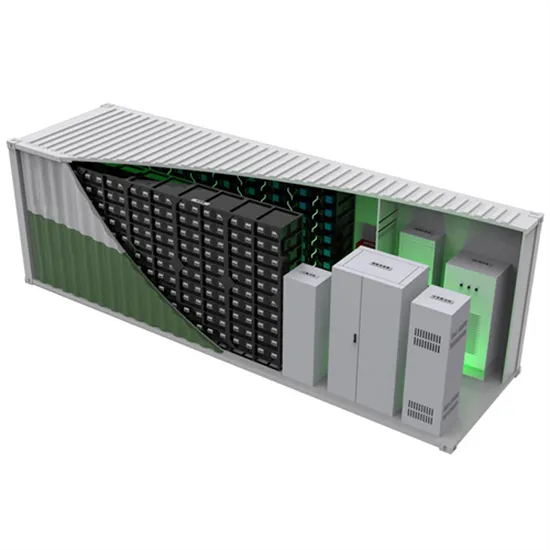

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.