How To Measure Battery Voltage Multimeter? A Step-by

Jun 23, 2025 · In today''s technologically driven world, batteries power a vast array of devices, from smartphones and laptops to electric vehicles and home appliances. Understanding how

How To Measure Car Battery Voltage With Multimeter?

Jun 23, 2025 · While the core principles of voltage measurement remain the same, the context and implications have expanded significantly. The ability to measure your car battery voltage

How to measure the total voltage of a battery pack

How do you calculate the voltage of a battery pack? The voltage of a battery pack is determined by the series configuration. Each 18650 cell typically has a nominal voltage of 3.7V. To

How to Measure Battery Voltage: A Step-by-Step Guide

Nov 1, 2023 · Measuring battery voltage is a straightforward process that can provide valuable insights into your battery''s health. By following these step-by-step instructions, you are better

How to Calculate Battery Voltage

Jun 17, 2025 · To calculate battery voltage, you measure the potential difference between the positive and negative terminals using a digital multimeter or voltmeter. It''s a quick, non

Battery Voltage: Basics and Importance for Optimal

Jan 30, 2025 · In this article, we''ll explore the importance of battery voltage, how it impacts performance, and what to consider when choosing a battery. We''ll also delve into common

How to Measure Battery Capacity

Apr 1, 2025 · A multimeter can measure voltage and current but cannot directly measure the total capacity of a battery. While it is useful for determining whether a battery is charged, you''ll need

How to measure the total voltage of the battery pack in

How do you measure open circuit voltage across a battery pack? If we assume one terminal of the battery pack is connected to ground, we can measure the open circuit voltage across each

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

How To Measure Battery Capacity Using Multimeter? Simple

Jun 23, 2025 · While you can use any multimeter to measure battery voltage, which is a necessary step, you cannot directly measure battery capacity with a standard multimeter.

Simplify Voltage and Current Measurement in Battery

Dec 23, 2023 · Assuming the temperature rises from 25°C to 85°C and the battery voltage is 4 V, we can easily calculate the real world error from one of our low-offset and low offset drift Op

How to calculate the heat dissipated by a battery pack?

Aug 22, 2018 · I have a battery pack consisting of 720 cells. I want to calculate the heat generated by it. The current of the pack is 345Ah and the pack voltage is 44.4Volts. Each cell has a

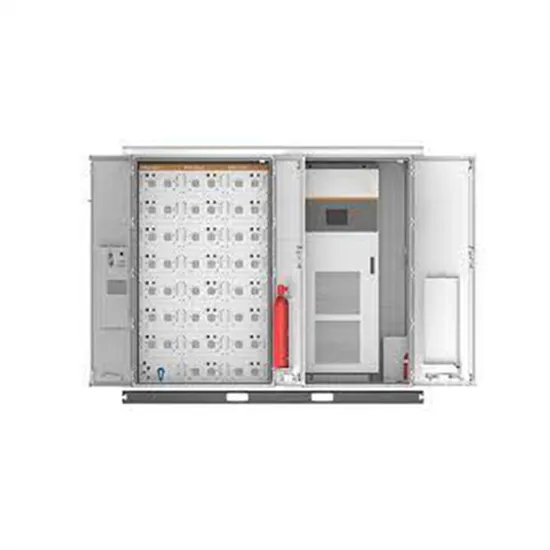

Battery Modules that Have Been Installed in the Cabinet

Use the DC voltage range of a multimeter to measure the voltages between the general positive and negative terminals of each battery string and the uncoated parts of the battery cabinet,

How To Measure Mah Of Battery With Multimeter?

Jun 23, 2025 · The short answer is that a multimeter alone cannot directly display a battery''s mAh rating. A multimeter is designed to measure instantaneous electrical properties like voltage,

How to measure the voltage of a lithium battery pack?

Jun 20, 2025 · To measure the voltage of a lithium battery pack, you''ll need the following tools: Multimeter: A digital multimeter is the most commonly used tool for voltage measurement. It

How to measure the total voltage of a battery pack

The voltage of a battery pack is determined by the series configuration. Each 18650 cell typically has a nominal voltage of 3.7V. To calculate the total voltage of the battery pack,multiply the

How to Check Battery Cell Voltage

Jun 17, 2025 · To check battery cell voltage, you use a digital multimeter to measure the voltage across each individual cell terminal. This simple process reveals the health and charge status

How to measure the voltage of batteries in the battery

One of the most useful measurements for a battery cell or pack is the open circuit voltage (OCV), but the considerations that must be made at the module or pack level differ from the cell level.

How To Measure Battery Voltage Multimeter? A Step-by

Jun 23, 2025 · Understanding how to use a multimeter to measure battery voltage allows you to proactively identify potential issues, prevent unexpected failures, and extend the operational

How Do You Find The Total Voltage In A Series

Dec 12, 2021 · How Do You Find The Total Voltage In A Series CircuitExploring electricity can be an exciting challenge, but it''s important to understand how

Battery Pack Voltage Measurement: What You Need to Know

Accurate measurement of each cell''s voltage and temperature during charge-discharge tests is essential, forming the basis for the overall performance assessment of the battery pack. Thus,

How to measure the voltage of batteries in the battery

If we assume one terminal of the battery pack is connected to ground, we can measure the open circuit voltage across each cell. This works because DMMs measure differential voltage, or the

How to measure the voltage of batteries in the battery

How to measure the current of a battery? To measure the current of a battery using a multimeter,follow these steps: Select the DC current function using the dialand keep it at

Simplify Voltage and Current Measurement in Battery

Dec 23, 2023 · Amplifier Usage in Battery Test Equipment In typical systems, a Buck converter is used as the power source for battery charging and a Boost converter is used for battery

How Battery Voltage Affects Performance: A Detailed Guide

Dec 14, 2024 · At its most basic, battery voltage is a measure of the electrical potential difference between the two terminals of a battery—the positive terminal and the negative terminal. It''s

How To Measure Battery Voltage With A Multimeter? Simple

Jun 23, 2025 · While multimeters can measure various electrical parameters like current and resistance, measuring voltage is arguably its most common application. For battery

6 FAQs about [How to measure the total voltage in the battery cabinet]

How to measure a battery with a reference voltage?

You can measure voltage battery with voltage reference. You need voltage reference with lower reference than you expect on battery (for example 1.235 V). Then you measure this voltage with your ADC. With this measurement you can now calculate ADC reference voltage, which should be equal to battery voltage.

How do you measure battery voltage?

Solution: Measure the internal resistance. How you can do that? Apply an additional known current and measure the difference in voltage. With that you get the internal resistance and with the measured current from above, you get the real battery voltage.

How to measure battery voltage Vb?

For example if you measure 300 with your ADC and your reference voltage Vr is 1.235 V then your battery voltage Vb is 4.2 V. Another similar, but more complex way is to use voltage divider on battery and use internal voltage of arduino for ADC reference.

How do you charge a battery with a buck converter?

To charge the battery, the buck converter is enabled while the first-stage voltage Op Amps and current-sense INA are used to measure battery voltage and charging current of the battery cell or battery pack.

What is a typical op amp power supply voltage?

The B+ and B- components are from the positive and negative terminals of the battery. Since the actual battery voltage might be higher than 5 V, the typical Op Amp power supply is 12 V. The TLV07, INA188 and INA125 all have 36 V max (±18 V) supply voltage, meeting system requirements.

What is battery test equipment?

Battery test equipment is used to verify battery pack functionality and performance prior to shipment to the customer. This application brief outlines three major functional tests that a battery tester performs while showing how to achieve the desired level of regulated error. ADC Figure 1. Traditional Battery Test Equipment Block Diagram

Learn More

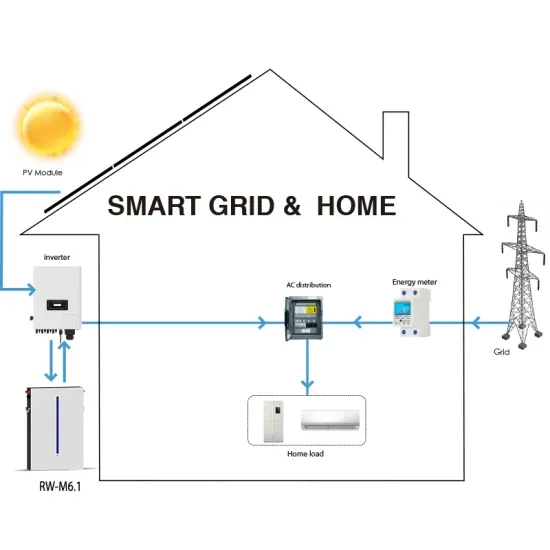

- How much is the voltage of the energy storage battery cabinet

- How to measure the capacitive coupling of the battery cabinet

- How to discharge the battery in the battery cabinet

- How much does it cost to replace a battery cabinet in Luanda

- Battery cabinet withstand voltage test photovoltaic current

- How big a battery can be placed in the a32 battery cabinet

- How to calculate the battery cabinet in the computer room

- How to connect the signal base station battery to the power distribution cabinet

- How to connect 32 batteries in a UPS battery cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.