Detecting and Mitigating Capacitive Coupling in Cables

Jul 20, 2025 · Learn how to detect and mitigate capacitive coupling between parallel serial and power cables. Discover techniques like physical separation, cable shielding, twisted pair

Capacitance measurement: Understand and use

Aug 22, 2006 · Even measuring "simple" passive components such as capacitors is not trivial, if you need high-accuracy results. Learn how to match the

How to Accurately Measure Capacitance Using A

Apr 17, 2024 · Capacitor meter can conveniently and quickly measure a single capacitor on site, without removing the connecting wire, thus avoiding a lot of

Capacitive coupling

Jul 14, 2015 · Take a simple 50% duty cycle square wave signal with high level of 9V and low level of 0V (e.g. from a CMOS 555 running from a 9V battery), and connect it to a scope via a

2.1 Mutual Capacitance Measurement

Jun 26, 2025 · Mutual capacitance touch sensors use a pair of electrodes for each sensor node and measure the capacitance between them. The sensor is formed where the electrodes are

How to Measure Capacitance

Oct 9, 2023 · Capacitance is an important electrical property that measures the ability of a component or circuit to store electrical energy. It is a fundamental concept in electronics and is

Capacitive Sensing Basics — CapTIvate ™

May 18, 2020 · Capacitive Sensing Basics ¶ This chapter provides a fundamental overview of self and mutual capacitance and capacitive sensing techniques.

Measurement Methods for Capacitances in the Range of 1

May 31, 2022 · The main challenges in designing measurement circuits for capacitive sensors are the wide measurement range, accuracy, sensitivity, and resolution. In addition, the existence

2.1 Mutual Capacitance Measurement

Jun 26, 2025 · The touch contact is a complex interaction of two competing effects: The finger forms a third electrode in the X-Y capacitor and increases the coupling between X and Y. This

IEEE 1802 – Capacitive Coupling Interference Testing for Battery

Capacitive coupling interference occurs when unwanted electrical signals are transmitted through capacitive couplings within a system. This can lead to false triggering of alarms, malfunctioning

Channel modeling and characterization of capacitive

As far as we know, few works conducted in a metal cabinet to realize NLOS capacitive coupling communication, and the modeling and characterization have not been systematically

Calculation of Coupling Capacitance in Planar Electrodes

Oct 10, 2014 · This work was motivated by the design of supercon-ducting qubits, where it is necessary to set capacitance coupling elements between qubits, resonators, and con-trol

Partial Discharge Measurement Coupling Methods

Feb 4, 2025 · Coupling Capacitors Figure 1 A coupling capacitor (C C) is a very common coupling method when performing a PD measurement as described in the IEC 60270 standard. When a

How to measure the capacitive coupling of the battery cabinet

How to measure capacitive coupling on pcb traces? Basically the coupling acts as an unknown capacitor between agressor and victim. By placing different real capacitors on the victim trace

Coupling between a cable and the main power

Jul 16, 2025 · Edit 1: If you want to measure capacitive coupling in your setup, i propose the following circuit: Disconnect source and load and instead short

How to Measure Capacitance: 8 Steps (with Pictures)

Jun 5, 2025 · Capacitance is the measure of how much electrical energy is stored in an object, such as a capacitor used in an electronic circuit. The unit for measuring capacitance is the farad (F), defined as 1 coulomb (C) of electric charge per volt...

6 FAQs about [How to measure the capacitive coupling of the battery cabinet]

What is a coupling capacitor (C C)?

A coupling capacitor (C C) is a very common coupling method when performing a PD measurement as described in the IEC 60270 standard. When a partial discharge event occurs, the coupling capacitor provides the devices under test (DUT) with a displacement current, which is measurable at the coupling devices (CPL).

How does a coupling capacitor measure a partial discharge?

When a partial discharge event occurs, the coupling capacitor provides the devices under test (DUT) with a displacement current, which is measurable at the coupling devices (CPL). Such an approach provides additional information about the test discharge (PRPD) measurement. OMICRON ofers standard coupling capacitors from 12 kV up to 100 kV.

How do you measure a coupling capacitor discharge (PRPD)?

discharge (PRPD) measurement. OMICRON ofers standard coupling capacitors from 12 kV up to 100 kV. When using a coupling capacitor without an integrated measuring impedance, the low side of the coupling capacitor has to be connected to the input of the CPL measuring impedance (basic test setup with measurement on ground potential).

What is a capacitance-voltage (CV) measurement?

Introduction The capacitance-voltage (CV) measurement has been one of the most important measurements for investigating the characteristics of the materials and the behavior of the devices.

How do mutual capacitance touch sensors work?

Mutual capacitance touch sensors use a pair of electrodes for each sensor node and measure the capacitance between them. The sensor is formed where the electrodes are placed close together, usually with interleaved segments to optimize the length of the parallel conductors forming the base capacitance of the sensor node. Figure 2-1.

What is the equivalent XY capacitance?

The equivalent XY capacitance is: Equation 2-1. Equivalent XY capacitance where C f is the series combination of C t, C h and C g. Mutual capacitance touch sensors use a pair of electrodes for each sensor node and measure the capacitance between them. The sensor is formed where the electrodes are placed close together, usually

Learn More

- How to measure the total voltage in the battery cabinet

- How much does it cost to replace a battery cabinet in Portugal

- How long does it take to repair a mobile lithium battery cabinet

- How to install the crossbeam of the battery cabinet

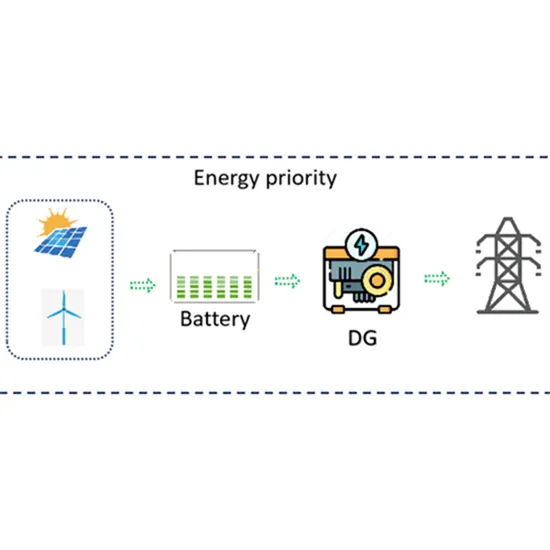

- How to check the battery photovoltaic of the energy storage cabinet

- How much does a lithium battery cost in an energy storage cabinet

- How to make a good brand of battery cabinet

- How to judge the quality of the battery cabinet

- How to discharge the battery in the battery cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.