How to Choose the Right Outdoor Battery Cabinet for Solar

May 7, 2025 · Compare top outdoor battery cabinets for solar systems. Learn about durability, weatherproofing, and security to choose the best cabinet for your needs.

Battery Cabinet Inspection Checklist | HuiJue Group E-Site

The Future of Cabinet Diagnostics With solid-state batteries entering commercial deployment, inspection paradigms are shifting. Tesla''s Q3 2024 patent filing reveals self-healing cabinet

Battery Storage Cabinets: A Comprehensive Buyer''s Guide

Jan 23, 2025 · High-quality cabinets with fireproofing, ventilation, and modular designs come at a higher price. You may qualify for government incentives or rebates when purchasing a battery

UPS And Battery Preventive Maintenance Scope Of Supply

Check integrity of battery cabinet (if applicable). Visual inspection of the battery cabinet and/or room to include. Check for NO-OX grease or acceptable compound on all connections (if

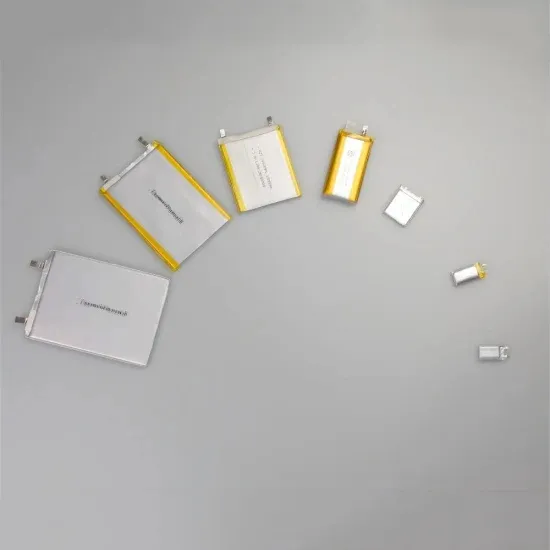

How to Detect the Quality of Lithium-ion Batteries

Assessing the quality of a lithium-ion battery requires a combination of visual inspection, performance testing, and verification of technical specifications. Start with a visual check: high

What Happens to Battery Safety Cabinets After a Fire Event?

May 29, 2025 · During these events, the cabinet experiences multiple types of damage: structural stress from intense heat, potential chemical contamination from battery electrolytes, and

Lithium Ion Battery Storage Cabinet | Storage Cabinet Supplier

We are a supplier of high-quality Lithium Ion Battery Storage Cabinet, featuring a powder-coated steel chamber with self-closing, oil-damped doors for safe storage and controlled battery

Lithium battery capacity cabinet principle and maintenance

May 29, 2025 · The key to maintaining lithium battery capacity division cabinets is regular maintenance and overhaul. Including cleaning equipment, tightening connectors, checking the

Battery cabinets prevent and reduce the risk of lithium batteries

To address this issue, manufacturers have developed a new type of safety equipment: battery storage cabinets, also known as lithium-ion battery charging and storage cabinets, designed to

How to Distinguish the Lithium Battery Quality Standards

Jan 8, 2025 · This article outlines six methods to assess the quality of lithium batteries: inspecting exterior and packaging, detecting capacity, evaluating voltage stability, investigating charging

Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Battery Storage Cabinets: Your Key to Efficient Power

Sep 30, 2024 · Battery storage cabinets are essential for keeping your energy systems safe, efficient, and long-lasting. They protect your batteries from hazards, improve their

Key Considerations for Installing a Lithium Battery Cabinet

Installing a lithium battery cabinet like Pytes'' V - BOX - OC needs attention to various factors. Space, environment, accessibility, security, foundation, electricals, and ventilation are crucial

The Hidden Dangers of Improper Lithium Battery Storage

May 14, 2025 · Lithium-ion battery storage cabinets like ESTEL reduce fire risks, toxic emissions, and property damage by offering fire-resistant and controlled environments.

Battery Cabinet

Feb 28, 2025 · To check for inadvertent grounding of the battery, use a digital multi-meter set to the DC Volts scale to measure the voltage between any battery terminal and either the cabinet

Battery cabinets for uninterruptible power supplies

Enerpower''s battery cabinets are designed to provide a complete, integrated battery management solution, ensuring optimal protection and long life for your critical equipment. Main Features of

Battery Cabinet Solutions: Ensuring Safe Storage and

Lithium-ion batteries are essential in powering tools, devices, and energy systems across industries, but they also come with inherent fire and explosion risks. To address these

What Is a Battery Rack Cabinet and Why Is It Essential?

Jun 14, 2025 · A battery rack cabinet is a specialized enclosure designed to securely house multiple batteries in energy storage systems. It ensures thermal management, safety, and

BATTERY CABINET INSPECTION AND MAINTENANCE

Using specialised storage and handling solutions like lithium-ion battery cabinets, fire suppression granules and lithium-ion battery charging stations, you''re not just keeping your workplace safe;

Inspection Checklist for Your Lithium-ion Battery

Apr 4, 2024 · Every week, do a check of the battery cabinet. This should include the daily task, plus some other key tasks including: REMEMBER: Consider

Understanding the Lithium

Mar 17, 2025 · Lithium - battery aging cabinets are equipped with advanced control systems that can precisely regulate charging and discharging parameters. For example, they can control

6 FAQs about [Check the quality of the battery cabinet]

How to check the battery capacity?

The capacity of a battery can be checked by measuring the discharge time (hours) at a constant current (I). The voltage usually remains the same when batteries are stacked in series, and the capacity is identical when batteries are stacked in parallel. Therefore, the voltage remains constant. Capacity (C) = discharge time (hours) × constant current (I).

How do you test a battery?

Battery Load Test: Perform a load test by providing a 200A load for 10-15 seconds. The voltage per battery should not fall below 9.6 V DC. Open/Short Circuit Check: Make sure the battery system has no open or short circuits. According to the inspection results, follow these recommendations:

What is a battery inspection checklist?

Regular battery inspections assist to ensure optimal performance & safety. Following this checklist makes sure that all important components are evaluated and any necessary steps are performed to keep the system operational. This detailed Battery Inspection Checklist ensures battery performance and safety.

How do I know if a battery is good?

Record the battery’s model. Voltage: Take note of the battery’s voltage rating. Ah/CCA: Display the battery’s capacity in ampere-hours (Ah) or cold-cranking amps (CCA). Unit Number: Write down the machine unit number in which the battery is placed. Note the machine’s model.

How do you check a battery in a washing machine?

Unit Number: Write down the machine unit number in which the battery is placed. Note the machine’s model. Last Fitment Date: Mention the date that the battery was last installed in the machine. The first level of inspection involves a thorough visual examination of the battery’s physical condition.

Why do you need a battery inspection?

Battery inspections are essential for ensuring the longevity and effective operation of electrical systems, particularly in industrial & commercial hardware. Regular inspections help to prevent unexpected failures, decrease downtime, and ensure the battery runs at its full capacity.

Learn More

- Bamako quality assurance battery cabinet price

- Battery Cabinet Quality Summary

- Malawi quality battery cabinet merchants

- Swedish quality battery cabinet recommendation

- Beirut quality battery cabinet price

- New energy battery cabinet performance check

- How to check the battery photovoltaic of the energy storage cabinet

- UPS battery cabinet voltage check

- How to check the network battery cabinet model

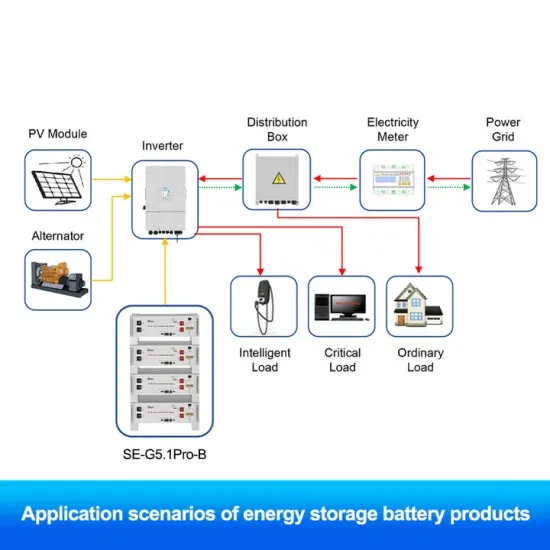

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.