UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Powerware 9395 Integrated Battery Cabinet (Model IBC

Jun 17, 2016 · 1 Introduction During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load.

164201687_1085_Rev_4_Web

Feb 28, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Model 1085 or 1085HR with a single battery voltage range is available to meet

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

How to check the battery status of the communication

Battery monitoring for communication network cabinets. EnerSys® has launched the ODYSSEY® Connect battery monitoring system, featuring proprietary technology to

Installing Network Cabinets, IT Cabinets, and Battery Cabinets

Moving Network Cabinets, IT Cabinets, and Battery Cabinets (Optional) Installing Side Panels for IT Cabinets (Optional) Taking Out rPDU Cables (Optional) Taking Out Industrial Connectors

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the

Eaton 93PM UPS 100-500 kVA User s and installation guide

Aug 27, 2024 · The purpose of the UPS Battery Switchgear is to ease the installation of external battery cabinets or battery racks. The UPS Battery Switchgear offering contains models with

Battery Cabinet

Feb 28, 2025 · To check for inadvertent grounding of the battery, use a digital multi-meter set to the DC Volts scale to measure the voltage between any battery terminal and either the cabinet

How Can Rack Mountable Battery Backups Optimize Network Cabinet

Mar 18, 2025 · Rack mountable battery backups maximize space efficiency in network cabinets by integrating vertically into standard 19-inch racks. They provide scalable power redundancy,

Eaton 9355 UPS (20/30 kVA) user guide

Dec 17, 2019 · Extended Battery Cabinet Optional EBCs are available with 2 strings or 4 strings, providing up to 2.7 hours of extended runtime. Options Cabinet The Options Cabinet is

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · battery cabinet are battery disconnect circuit breaker alarm lead assemblies. Refer to the power system installation manual to use these alarm leads to connect the battery cabine

Eaton-Battery-Handbook-BAT11LTA.PDF

Apr 20, 2018 · Eaton batteries are backed by our service network of trained and qualified battery service engineers who are available to install and maintain your batteries. Beyond the

List of battery models for DC distribution cabinets

EverExceed VRLA battery assembly cabinets are very durable, and easy to install.Engineered for use with most type of battery terminal models, these cabinets can fit a wide variety of

UPS backup power 10 buying tips

Oct 6, 2024 · Selecting the right UPS battery backup for your network closet or IDF can be a confusing process. This uninterruptible power supply (UPS) buying guide is designed to help

What Are Battery Rack Cabinets and Why Are They Essential?

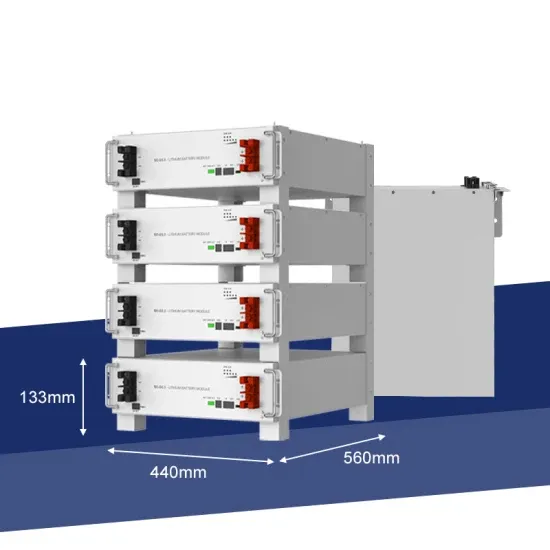

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

The three-phase UPS battery handbook

Apr 3, 2025 · The battery or battery cabinet will also feature a sticker for each time the batteries have been recharged while in storage. Stored batteries require charging periodically to avoid

How do I locate battery information regarding multiple types of

Oct 19, 2016 · I am looking for battery information required for shipping Cisco switches and servers as it is required for shipment. If they contain a battery, need to know type (Lithium

Liebert® GXT4 Installer/User Guide

May 7, 2019 · The products covered by this instruction manual are manufactured and/or sold by Vertiv. This document is the property of Vertiv and contains confidential and proprietary

6 FAQs about [How to check the network battery cabinet model]

How do I connect a ups to a battery cabinet?

Locate the UPS-to-battery cabinet breaker sensing cable inside the first battery cabinet. Mate the connector on this cable with the matching connector in the cabinet (see Drawing 164201536-8 on page A-17). Route the other end of this cable through conduit (top or bottom entry) to UPS cabinet and connect to terminal strip TB2.

What is a battery cabinet?

The battery cabinet is designed for industrial or computer room applications and should be handled with appropriate care. This battery cabinet contains LETHAL VOLTAGES. All repairs and service should be performed by AUTHORIZED SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE PARTS

How do I install a battery cabinet?

The installer should be familiar with the installation requirements and techniques to be used in securing the battery cabinet to a relay rack or wall. The battery cabinet is designed to mount on a wall or a standard 23” wide relay rack. Refer to Figure 3 and install the 23” relay rack mounting angles to the battery cabinet.

How do I install a battery cabinet breaker?

Locate the battery cabinet-to-battery cabinet breaker sensing cable in the first battery cabinet. Route this connector into the cabinet to the immediate left and mate with the matching connector in that cabinet (see Drawing 164201536-8 on page A-17). If installing multiple battery cabinets, proceed to Step 3; otherwise, proceed to Step 5.

How do I connect a battery to a ups?

Connect and route cables from positive (+) and negative (–) terminals in the bottom of the first battery cabinet into the UPS cabinet. Connect the (+) lead to terminal E4 (+) and the (–) to terminal E5 (–) in the UPS cabinet.

How do I connect A Powerware 9390 ups to a battery cabinet?

Refer to the appropriate Powerware 9390 UPS Installation and Operation Manual, as referenced in paragraph 1.6, for UPS cabinet terminal locations. A UPS‐to‐battery wiring harness is supplied inside the first battery cabinet. Use pressure and bus bar terminations, as necessary, for connecting cables between the UPS and battery cabinet.

Learn More

- How to check the model of lithium iron phosphate battery station cabinet

- How to check the battery photovoltaic of the energy storage cabinet

- How to view distributed power generation at the battery exchange cabinet site

- How to return batteries to the battery cabinet

- How is the battery technology of photovoltaic energy storage cabinet

- How long does it take to repair a mobile lithium battery cabinet

- How much does a new energy battery cabinet cost per kilowatt-hour

- How to choose the main incoming wind power of UPS battery cabinet

- How to assemble the lithium battery station cabinet

Industrial & Commercial Energy Storage Market Growth

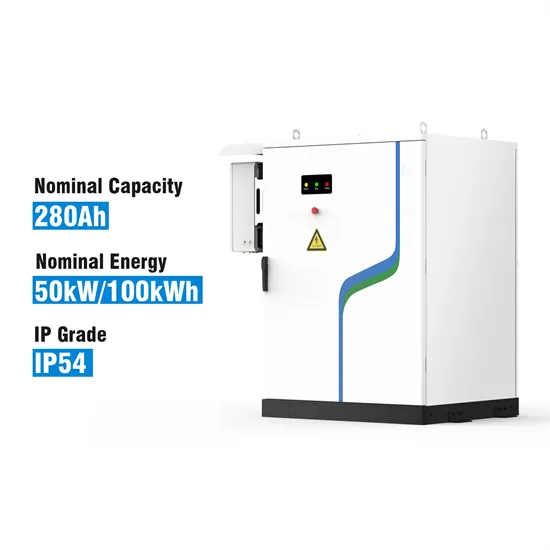

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

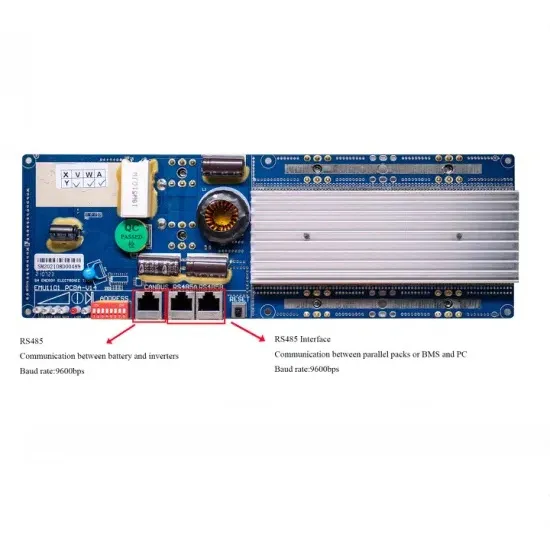

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.