BATTERY INSPECTION CHECKLIST

Oct 10, 2024 · Note: Battery should be Replaced if ~ Point 2,4 & 7: Badly damage ~ Point 16: < 6,5 VDC or < 300A Battery should be Recharged if ~ All Visual Inspection OK ~ Point 16 in

Battery Cabinets Manufacturer

Jan 31, 2025 · As a trusted battery cabinet manufacturer, we specialize in designing high-quality cabinets that ensure the safe storage of batteries. Our battery cabinets are built to protect

Choosing the Right Lithium Ion Battery Cabinet: A Complete

May 1, 2025 · Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and storage solutions to protect

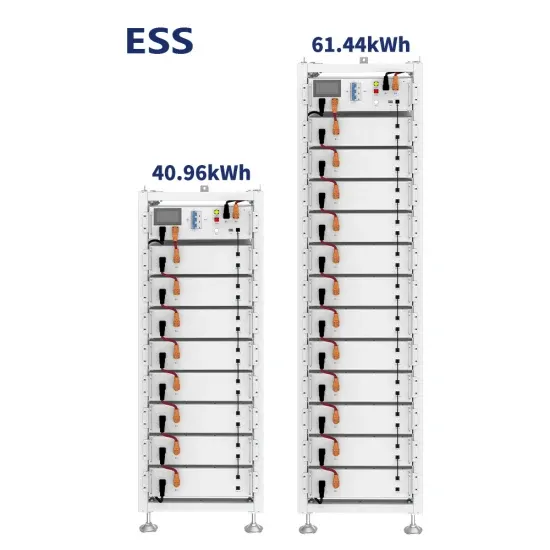

Energy Storage Battery Pack Enclosure size optimization and

May 9, 2025 · In-depth analysis of ESS Battery Enclosure size matching and compatibility optimization technology, covering large-capacity battery cells, CTP integration, liquid cooling

Lithium-Ion Battery Charging Cabinet: Safe, Compliant, and

Aug 15, 2025 · High-quality charging cabinets are purpose-built with materials and features designed to address the unique hazards of lithium-ion battery chemistry. Fire-resistant steel,

Specs Vertiv GXT4-48VBATTE UPS battery cabinet

Aug 10, 2024 · Recommended to protect mission-critical equipment, Liebert GXT4 is a true on-line UPS that delivers continuous, high-quality AC power with no break when transferring to

Lithium Ion Battery Storage Cabinet | Storage Cabinet Supplier

We are a supplier of high-quality Lithium Ion Battery Storage Cabinet, featuring a powder-coated steel chamber with self-closing, oil-damped doors for safe storage and controlled battery

How to Choose the Right Battery Cabinet for Your Needs

Jan 30, 2025 · Choosing the right battery cabinet involves careful consideration of your needs, safety features, build quality, and maintenance. Think about how the cabinet will be used, and

New UL Standard Published: UL 1487, Battery Containment

2 days ago · Learn about the first edition of UL 1487, the Standard for Battery Containment Enclosures, a binational standard for the United States and Canada published by UL

Battery Storage Cabinets: A Comprehensive Buyer''s Guide

Jan 23, 2025 · Battery storage cabinets play a vital role in energy systems. They protect batteries from damage, reduce safety risks, and improve performance. You need one to ensure your

US-HXCAB-RS-002 new table

Jun 3, 2020 · The HX battery cabinet offering now makes the DataSafe HX battery the ideal choice to optimize your UPS system installation, while offering flexibility in allowing customized

What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · Battery energy storage cabinets must comply with several critical criteria: 1. Material durability, ensuring resilience against environmental factors, 2. Adequate thermal

GE Industrial Solutions SG Series UL LISTED BATTERY CABINETS

PAGE 1 GE Digital Energy Power Quality Installation – Operation – Maintenance Guide Uninterruptible Power supply Digital Energy™ SG Series UL LISTED BATTERY CABINETS

Maximize Safety and Space: The Essential Guide to Battery Storage Cabinets

Summary: Battery storage cabinets are crucial for maximizing safety and organization in battery management. They provide a secure, organized space for batteries, reducing hazards like

Do Lithium Ion Batteries Require A Battery Room? Storage

Apr 16, 2025 · In summary, lithium-ion batteries do not always require a dedicated battery room; however, proper storage requirements, including temperature, humidity, and ventilation, are

Energy storage cabinet quality standards

Nov 16, 2024 · Energy storage cabinets, typically equipped with advanced battery systems, store electricity during periods of low demand or when renewable energy sources, such as

Comprehensive Guide to Lithium Battery Cabinet Safety and

A high-quality lithium battery cabinet plays a crucial role in ensuring fire safety, minimizing chemical hazards, and meeting workplace regulations. This blog provides a complete overview

Energy Storage Cabinet: From Structure to Selection for

For renewable system integrators, EPCs, and storage investors, a well-specified energy storage cabinet (also known as a battery cabinet or lithium battery cabinet) is the backbone of a

Battery Cabinet Performance Testing: The Critical Gateway to

Can your battery cabinets withstand real-world operational stresses while maintaining optimal efficiency? As global energy storage capacity surges past 1,500 GWh in 2024, performance

6 FAQs about [Battery Cabinet Quality Summary]

What is a battery cabinet?

A battery cabinet is a particular type of storage cabinet that reduces the risks associated with lithium-ion batteries. These innovative cabinets create a safer environment in which workplaces can charge and store their li-ion cells.

What should a battery cabinet have?

Handles – provides an easy way to handle the battery cabinet. Battery holding brackets – they ensure the battery is always in a fixed position (no movement). Cooling plates – some have cooling plates that help to control the enclosure temperature. Insulation system – insulation is also a safety measure a battery cabinet should have.

What rating should a battery cabinet have?

Indoor battery cabinet should have at least NEMA 1 rating. On the other hand, outdoor enclosures for batteries should have a NEMA 3R rating. It is important to note that the NEMA and IP rating varies depending on where you will install the enclosure. Indoor Battery Box Enclosure 2. Mounting Mechanism for Battery Cabinet

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

Why should you have a battery cabinet?

For example, dropping a battery or leaving it in a hot location can result in irreversible damage to the battery cell, which can lead to ignition or explosion. Providing a battery cabinet can reduce these risks by encouraging safe handling and storing practices within your team.

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

Learn More

- How to judge the quality of the battery cabinet

- Egyptian quality battery cabinet recommendation

- Beirut quality battery cabinet price

- Check the quality of the battery cabinet

- Malawi quality battery cabinet merchants

- Swedish quality battery cabinet recommendation

- Base station energy storage battery cabinet base station

- Indonesia Energy Storage Cabinet Battery Wholesale

- HXD1C battery cabinet function

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.