UPS Battery Sizing

Apr 8, 2012 · Example of UPS battery sizing. Select the battery model number and quantity (using the typical watts per cell table) for a 300 kVA UPS, 94% efficiency, power factor of 0.8, for a

How to choose the quantity of UPS batteries

Aug 15, 2025 · How to Calculate the Number of Batteries Equipped with UPS. Battery calculation method: For example, a 40KVAUPS with a DC voltage of 384V and 32 12V batteries per

Sizing for UPS batteries

5 days ago · To achieve optimal performance, properly sizing the UPS batteries is essential. This guide provides a detailed overview of how to determine the right battery size for commercial

Liebert ITA2 External Battery Cabinet System

The Vertiv Liebert ITA2 is a compact, rack-tower convertible uninterruptible power system (UPS) that employs true online, double-conversion technology that continuously conditions and

Vertiv EnergyCore Battery System

Feb 13, 2025 · EnergyCore Battery Cabinet The Vertiv EnergyCore is the first lithium-ion battery cabinet engineered specifically for data center use. Its compact design, proven safety features,

UPS Battery Sizing Calculator – IEEE & IEC Guide with Formulas

Apr 20, 2025 · Calculate required battery capacity (Ah), series & parallel battery counts and total runtime factors. Includes inverter/rectifier efficiency, depth-of-discharge and derating. If using

How to choose the quantity of UPS batteries

Aug 15, 2025 · How to Calculate the Number of Batteries Equipped with UPS Battery calculation method: For example, a 40KVAUPS with a DC voltage of 384V and 32 12V batteries per

How to Calculate the Number of Batteries for UPS Systems

Jan 21, 2025 · An Uninterruptible Power Supply (UPS) system is a critical component of modern power protection, providing short-term power backup to ensure the continuous operation of

Vertiv HPL 9540A Lithium-ion Battery Energy Storage

Sep 9, 2019 · The Right Battery for the High Performer If the UPS is only as good as the battery, it''s important to select the right one for the application. There are a variety of lithium-ion

Flyer_Battery_Cabinet_English

Oct 17, 2012 · Remark: This cabinet can accommodate 2 strings of 44 battery blocks each. A combination of internal-external batteries is not possible. When connecting this external

Eaton UPS fundamentals handbook

Jul 2, 2025 · Positive grid corrosion has been the most common end-of-life factor for UPS batteries, which is a result of the normal aging process due to UPS battery chemistry and

How To Correctly Size A UPS Battery

The battery within a UPS must be sized to provide a specified runtime (also known as battery autonomy), in minutes or hours, at a specific load. Load-specific factors are incorporated into a

Ups Battery Cabinets | Batteries And Power Supplies

Its new auto detection feature makes installation easy and fast ensuring the UPS configuration is complete and accurate for the solution installed. Power and communications ports allow up to

6 FAQs about [UPS battery cabinet battery quantity]

How are UPS batteries sized?

UPS batteries are sized in ampere-hours (Ah), referring to the amps they can supply per hour. The battery within a UPS must be sized to provide a specified runtime (also known as battery autonomy), in minutes or hours, at a specific load.

How do you measure UPS battery capacity?

The capacity of UPS batteries is measured in ampere-hours (AH). This unit defines the battery’s ability to deliver a specific current over time. Sizing the battery correctly ensures the UPS can support the connected load during power outages for the desired duration. Calculate the total power consumption of all connected equipment.

How many batteries do I need for a 300 kVA ups?

Select the battery model number and quantity (using the typical watts per cell table) for a 300 kVA UPS, 94% efficiency, power factor of 0.8, for a backup time of 15 minutes. The UPS battery bus voltage is 480 V. The typical table is for 12 V batteries (six cells of 2 V each). Quantity of batteries per bank = 480/12 = 40 batteries

How does the size of a UPS battery affect its capacity?

The size of a UPS battery affects its capacity, measured in volt-ampere hours (VA-h) or amp-hours (Ah). A bigger battery can give more power for a longer time. Choosing the right UPS battery size is key. It makes sure you have enough power backup, giving you the time to safely shut down or switch to another power source during an outage.

How much battery capacity does a ups need?

Step 5: Verify the Final Answer The final battery capacity required for this setup is 267 AH, ensuring the UPS can provide sufficient backup power for 2 hours while accounting for energy losses and battery aging. Maintain a stable ambient temperature around 25°C.

Why is a ups Battery sizing important?

A UPS is vital to maintain continuous power during outages, voltage sags, and transient electrical events. Correct battery sizing ensures autonomy, prevents over-discharge, optimizes costs, and meets IEEE and IEC standards. Calculate required battery capacity (Ah), series & parallel battery counts and total runtime factors.

Learn More

- 24 UPS battery cabinet installation site

- UPS battery cabinet size base station

- UPS battery cabinet is made of aluminum

- UPS battery cabinet voltage check

- 8 UPS battery cabinet dimensions

- About UPS lithium battery site cabinet

- How to make a UPS battery cabinet

- UPS battery cabinet module

- Israel UPS battery cabinet full set production direct sales

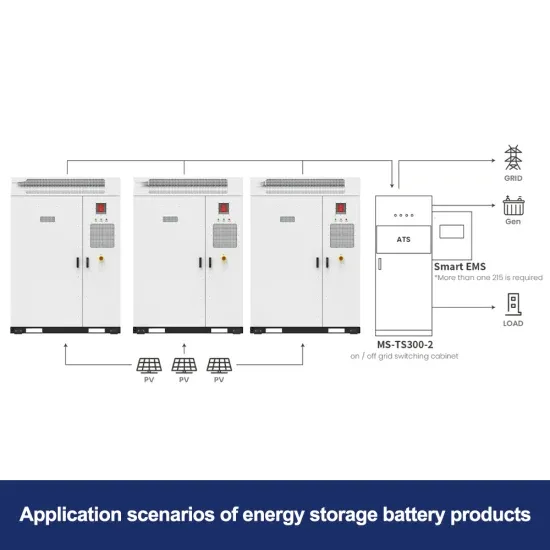

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

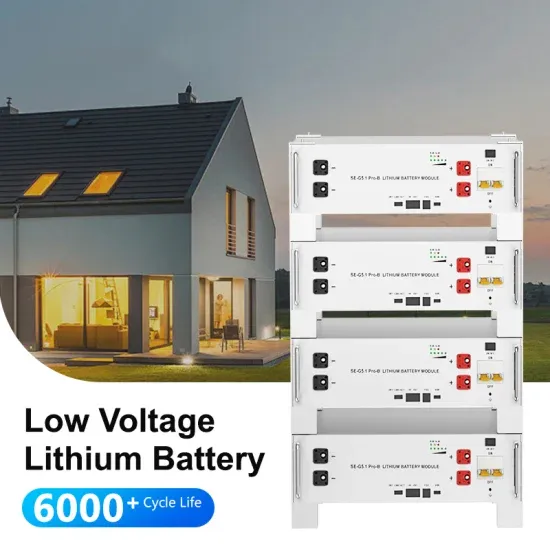

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.