China Distribution Panel Ups Cabinet, Distribution Panel Ups Cabinet

The Distribution Panel Ups Cabinet is a key item within our extensive Power Distribution Cabinet & Box selection.To distinguish between suppliers in China, evaluate their manufacturing

UNDERSTANDING UPS SYSTEMS AND BATTERIES

Jul 17, 2024 · Battery types Batteries are available in a range of technologies, including lead-acid, nickel- cadmium, lithium ion, lithium-sulfur, aluminum-ion, nickel-metal, and more. Of all these,

China Ups Battery Cabinet: Made-in-China Ups Battery Cabinet

China Ups Battery Cabinet Directory provides list of Made in China Ups Battery Cabinet Products supplied by reliable China Ups Battery Cabinet Manufacturers, Traders and Companies.

Custom Aluminum Battery Cabinet for Bad Environment with

May 13, 2024 · Product Description Custom Aluminum Battery Cabinet for bad environment with CE&Rohs UPS battery cabinet is safe to use , Electronics, Filter,

China Ups Battery Cabinet, Ups Battery Cabinet

China Ups Battery Cabinet wholesale - Select 2025 high quality Ups Battery Cabinet products in best price from certified Chinese UPS Battery manufacturers, Storage Battery suppliers,

VRLA battery cabinets

3 days ago · - Designed according to the specific UPS model for easy connections, correct recharge current and appropriate discharge rating to optimize battery life. - Modular hot-swap

Battery Backup Systems

Aug 14, 2023 · Battery Backup Systems Consolidated battery backup system (BBS) designed to power ATC, NEMA M, P & 336 (or similar style) trafic controller cabinets Ideal solution for

Battery Storage Cabinet | AEC UPS

Jul 25, 2025 · The battery cabinet for UPS | UPS is an accessory designed to extend the autonomy of the UPS. Each UPS has its own external battery cabinet and the number of

BATTERY CABINETS-Battery Cabinet-KEBOS POWER CO., LTD.-

Battery cabinets for all KEBOS UPS from 1KVA up to 1200KVA Power Range.The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 17AH to 250AH.The

Choosing Battery Enclosure Material: Metal or

Feb 7, 2025 · Selecting the right material is critical when it comes to battery enclosures for lithium battery applications. The enclosure protects the battery

6 FAQs about [UPS battery cabinet is made of aluminum]

Does unified power offer battery cabinets?

Unified Power offers a complete line of battery cabinets for both UPS and Telecom Applications. These cabinets can be configured to match OEM cabinets and offer a competitive option for system upgrades or new projects. Features Space saving foot print is the industry’s most compact design.

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

Are ups and battery cabinets dangerous?

The UPS and/or battery cabinets might be configured to look like standard computer equipment racks. There are two primary hazards of concern: electrical and fire. Open rack batteries expose potentially lethal voltage to any person coming in contact with them.

What material should a battery box be made of?

In most cases, you will find aluminum and stainless steel battery cabinets. Of course, we have galvanized steel, plastic, and composite materials. A good material for the battery box should be: So far, aluminum and stainless steel guarantee better performance. Apart from these 4, you may classify battery box enclosures depending on:

Do battery cabinet enclosures have a DIN rail?

Many enclosures have DIN rail. Electronic components –modern battery cabinet enclosures have sensors for smoke, shock, humidity, temperature, and moisture. These are safety measures to ensure the environment within the battery cabinet is safe. However, such enclosures are costlier.

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

Learn More

- UPS battery cabinet placed close to the ground

- Can I open the battery cabinet after the UPS is turned off

- UPS battery cabinet voltage check

- Is the new energy battery cabinet made of aluminum alloy

- UPS battery cabinet production and sales

- UPS battery cabinet battery quantity

- UPS battery cabinet is 3p wind power

- Israel UPS battery cabinet full set production direct sales

- Irish UPS battery cabinet manufacturer

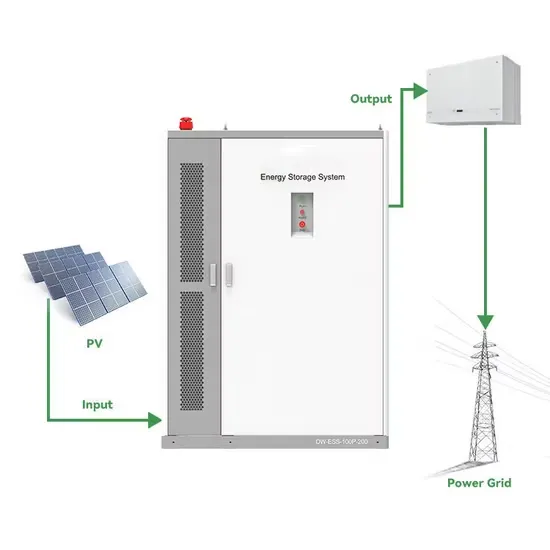

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.