A Comprehensive Guide To Safe Battery Storage | UPS Pune: The Best UPS

Authorised personnel must receive battery safety training, and access to the battery room must be restricted to authorised personnel. Exhaust systems must be installed in battery rooms, and

ZincFive BC Series UPS Battery Cabinets

Jun 9, 2023 · ZincFive BC Series UPS Battery Cabinet are carefully designed and manufactured to ensure that they are safe and reliable products when used properly. To ensure the safe and

UPS isolated neutral | Information by Electrical Professionals

Sep 25, 2009 · The manufacturer says that when there''s a standby genset with a 4-pole ATS, during the switchover to the generator startup in the event of an emergency, the UPS might

Eaton UPS fundamentals handbook

Jul 2, 2025 · Handbook. From plug and receptacle charts and facts about power problems to an overview of various UPS topologies and factors affecting battery life, you''ll find a wealth of

Eaton EBC Installation and Operation Manual

Sep 2, 2024 · Chapter 1 Introduction The Eaton® External Battery Cabinet (EBC) provides extended emergency short-term backup power for the 93E 80-200 kVA, 93E 300–400 kVA

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

Battery Cabinets. Vertiv Liebert Series 610 300-450kVA Multi

Refer to Figures 26 through 28 . The battery cabinet cells range from 90 to 150 ampere-hours. The same model battery cabinet may be paralleled in multiple cabinet strings for additional

BC Series UPS Battery Cabinets

Nov 8, 2023 · Safety Symbols ZincFive BC Series UPS Battery Cabinet are carefully designed and manufactured to ensure that they are safe and reliable products when used properly. To

Just bought my first UPS. Where is a safe place

Feb 22, 2011 · I bought a APC UPS XS 1300 today, and I currently have it set up on the floor next to my desk (see pic below.). The floor is carpeted. Is it safe to

System earthing arrangements for installations comprising UPSs

4 days ago · When batteries are not installed in a cabinet, i.e. generally in a special room, the measures presented at the end of this chapter should be implemented. Note: The TN system

General requirements for the installation of UPS

Oct 21, 2023 · Install battery protection devices close to the battery, ideally in the battery rack or in a nearby enclosure. If multiple battery banks are used, it''s

Just bought my first UPS. Where is a safe place

Feb 22, 2011 · biggest problem with carpet or being with in few inches of the floor is dust. Think about UPS is the fans in them never kick on until it is operating

MISSION CRITICAL FACILITIES DESIGN

Apr 30, 2015 · When commercial power is interrupted in mission critical facilities, businesses are placed at significant risk to lose revenues, clients, and/or corporate image. The emergency

How to design a grounded power supply system

Transformerless uninterruptible power supply (UPS) systems operate ungrounded during power transfer to a backup source, but a robust grounding design can accommodate the requirement

Eaton-Battery-Handbook-BAT11LTA.PDF

Apr 20, 2018 · The battery or battery cabinet will also feature a sticker for each time the batteries have been recharged while in storage. Stored batteries require charging periodically during

VertivTM Liebert® ITA2 Battery Cabinet

Feb 27, 2020 · Refer to the illustration, "Cabling 3U Cabinets in Parallel," above, and connect the UPS-to-battery cable to Connectors A on each battery cabinet in the battery string.

Guidelines for storage & usAGE of lead acid batteries

May 19, 2022 · Lead-acid batteries are the most widely used electrical energy storage, primarily for uninterrupted power supply (UPS) equipment and emergency power system (inverters).

Can the battery cabinet be located together with the

Do battery cabinets need to be locked? Battery cabinets must enclose the batteries behind locked doors accessible only to authorized personnel. As long as the cabinets are kept locked, they

PDU8000 电池开关柜-T 快速指南 (02408391)

Sep 14, 2023 · C:024083913 Tools / 安装工具 5 Installing a Battery Switch Cabinet / 安装电池开关柜 PDU8000 Battery Switch Cabinet-T Quick Guide 5.1 Checking Before Installation / 安装前

Analysing Battery Cabinet and Battery Racks

Apr 29, 2022 · As per the manufacturers of Industrial Battery Cabinet, the battery racks should ideally be close to the UPS, while the battery cabinets should be adjacent to the set-up of the

BC Series UPS Battery Cabinets

Jun 9, 2023 · Safety Symbols ZincFive BC Series UPS Battery Cabinet are carefully designed and manufactured to ensure that they are safe and reliable products when used properly. To

6 FAQs about [UPS battery cabinet placed close to the ground]

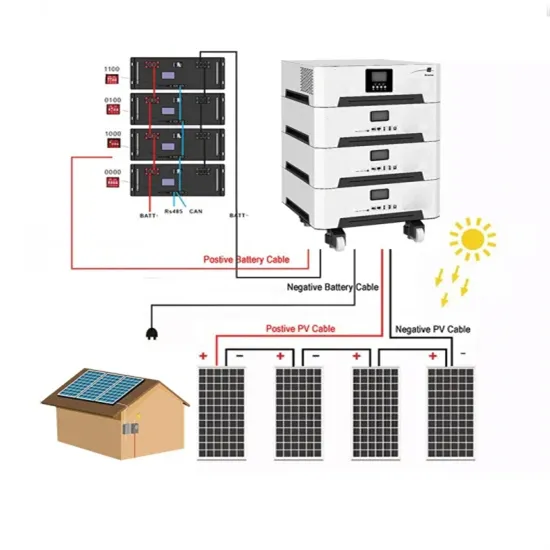

How do I WIRE an external battery cabinet?

If you purchased an external battery cabinet, an electrician must wire the battery to the UPS as described in Chapter 7, “External Battery Cabinet Installation.” Continue to the startup section in the Eaton FERRUPS FE/QFE UPS (500 VA–18 kVA) User's Guide. Hardwired Installation... Page 6 Battery Cabinet Installation” for wiring connections.

Can a battery be installed in a cabinet?

This component can disturb the operation of certain protection devices, notably RCDs used for the protection of persons. (see Fig. N23) All installations satisfy the applicable requirements because the equipment is housed in cabinets providing a degree of protection IP 20. This is true even for the battery when it is housed in a cabinet.

Where should the ups be installed?

The UPS should ideally be installed close to the loads. If the distance between the load and the UPS is greater, we must take into account the voltage drop based on the length of the cable and take appropriate measures, such as oversizing the cable.

Where should a battery protection device be installed?

Install battery protection devices close to the battery, ideally in the battery rack or in a nearby enclosure. If multiple battery banks are used, it’s recommended to have a common isolator with a fuse or an MCCB (Molded Case Circuit Breaker) and an individual battery isolator for each battery string.

Where should a UPS terminal be located?

Terminals are typically located at the bottom, and many UPS units have provisions for bottom cable entry. Due to limited space and bending requirements, it’s best to use single-core flexible copper cables. If armored aluminum cables are used, elevate the UPS system to ensure the required cable bending radius.

How to choose the right cables for UPS installation?

Choosing the right cables for UPS installations is critical. Incorrect cable selection can lead to problems like overheating, fire risks, and early failure. It’s also important to pick the best installation method and routing. Use the same cable size for input and output, ensuring it can handle the thermal current continuously.

Learn More

- UPS battery cabinet has voltage to ground

- How big a battery cabinet can be placed in the center box

- 32 battery cabinet UPS installation site

- How to choose the main incoming wind power of UPS battery cabinet

- Standard distance between UPS battery cabinet and host

- Prague UPS battery cabinet quotation

- UPS battery cabinet is made of aluminum

- How big a battery can be placed in the a32 battery cabinet

- UPS battery cabinet battery quantity

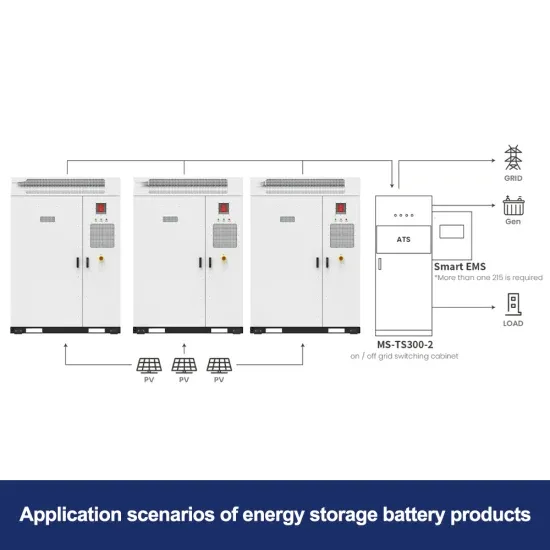

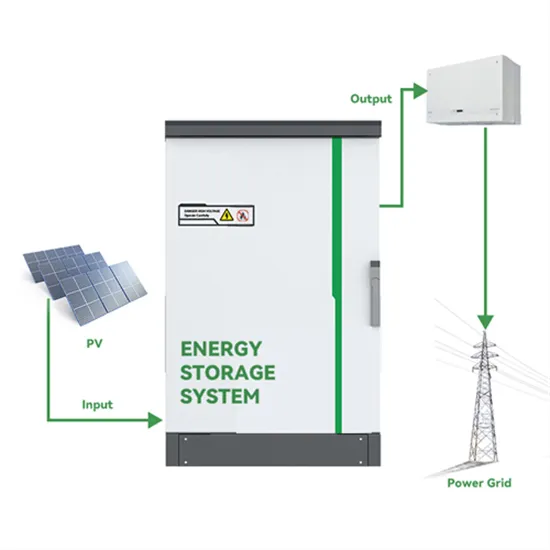

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.