Eaton-Battery-Handbook-BAT11LTA.PDF

Apr 20, 2018 · The battery or battery cabinet will also feature a sticker for each time the batteries have been recharged while in storage. Stored batteries require charging periodically during

Installation and design requirements of large

Apr 7, 2022 · 2. Basic installation design parameters that users should consider when purchasing UPS Due to the user''s load and the power factor of the UPS,

Eaton s lithium-ion UPS battery Q&A

Mar 21, 2025 · This document will serve as a guide for Eaton salespersons, sales support personnel, engineering clients, and end users who have questions regarding the lithium

Stationary UPS Sizing Calculations – Part Seven

5 days ago · Preferably the UPS has to be installed close to the loads. If the distance between the load and the UPS is higher, we must consider the voltage drop based on the distance of the

Placement of UPS. Minimum distance between several UPS. Back-UPS

Jun 29, 2021 · Make sure that you keep your APC UPS in a cool, dry location with plenty of ventilation. Ideally, the temperature where your UPS is kept should not >exceed 75° F (24° C).

General requirements for the installation of UPS

Oct 21, 2023 · The UPS should ideally be installed close to the loads. If the distance between the load and the UPS is greater, we must take into account

Eaton UPS fundamentals handbook

Jul 2, 2025 · Handbook. From plug and receptacle charts and facts about power problems to an overview of various UPS topologies and factors affecting battery life, you''ll find a wealth of

Installation Environment and Clearance Requirements

Do not install the UPS in environments with conductive metal scraps in the air. The optimal operating temperatures for valve-regulated lead-acid (VRLA) batteries are 20–30°C. Operating

UPS + Isolation Transformer Battery Backup

Aug 26, 2020 · Inadequate (much shorter than usual) backup time, premature low battery alarm sounds, and persistent Low/Replace Battery LED illumination are all good signs that the

Eaton three-phase UPS battery handbook

Apr 3, 2025 · Battery failure is a leading cause of UPS load loss. Knowing how to properly maintain UPS batteries will help you manage your IT power more efficiently and avoid power

Requirements for a Third Party Battery Solution

The distance between the battery bank and the UPS must not exceed 200 m (656 ft). Contact Schneider Electric for installations with a longer distance. NOTE: To minimize the risk of

Easy UPS Modular Battery Cabinet

Sep 18, 2020 · When replacing batteries, always replace with the same type and number of batteries or battery packs. Refer to the label in the classic battery cabinet for information on

Ventilation and Thermal Management of Stationary

Jan 10, 2023 · The purpose of the document is to build a bridge between the battery system designer and ventilation system designer. As such, it provides information on battery

第四期 UPS电源系统配置 之 电池柜

Oct 20, 2022 · 大家也可以通过关注公众号"UPS电源系统配置",了解更多知识,快捷使用小程序。 1. 进入"UPS电源系统配置"的电池柜界面 2. 电池柜的命

Liebert EXM 80kVA ~ 200kVA UPS User Manual

Jan 19, 2024 · Note 1: When the battery cabinet is installed near the UPS, the maximum allowable ambient temperature is dependent on the battery rather than the UPS. Note 2: If the UPS is

Guidelines for storage & usAGE of lead acid batteries

May 19, 2022 · There are primarily three kinds of batteries used in UPSs—vented lead acid (VLA) (also called flooded-cell),valve-regulated lead-acid (VRLA), and sealed or maintenance-free

Stationary UPS Sizing Calculations – Part Seven

5 days ago · Stationary UPS Sizing Calculations – Part Seven in Article " Stationary UPS Sizing Calculations – Part Six ", we explained the following: 1-

Battery Room Ventilation and Safety

Mar 15, 2023 · This course describes the hazards associated with batteries and highlights those safety features that must be taken into consideration when designing, constructing and fitting

UPS WITH A BATTERY SYSTEM 101. EDUCATION FOR

Jan 10, 2023 · The most common topology of a UPS with a battery system is the dual conversion technology with a line up and match battery cabinet with VRLA batteries. The following outline

UNDERSTANDING UPS SYSTEMS AND BATTERIES

Jul 17, 2024 · Battery types Batteries are available in a range of technologies, including lead-acid, nickel- cadmium, lithium ion, lithium-sulfur, aluminum-ion, nickel-metal, and more. Of all these,

6 FAQs about [Standard distance between UPS battery cabinet and host]

What are the floor space requirements for UPS?

Floor Space Requirements. Preferably the UPS has to be installed close to the loads. If the distance between the load and the UPS is higher, we must consider the voltage drop based on the distance of the cable and suitable action like oversizing the cable needs to be considered.

How to choose the right cables for UPS installation?

Choosing the right cables for UPS installations is critical. Incorrect cable selection can lead to problems like overheating, fire risks, and early failure. It’s also important to pick the best installation method and routing. Use the same cable size for input and output, ensuring it can handle the thermal current continuously.

How much space do you need for UPS?

Keep at least 1 meter of clear area in front of the unit for service personnel. Confirm that the floor can support the UPS and batteries, considering the unit’s weight, which varies based on capacity and type. What is the general arrangement of UPS system? Most UPS units operate optimally at temperatures below 40°C (104°F).

How to choose the right ups?

Preferably the UPS has to be installed close to the loads. If the distance between the load and the UPS is higher, we must consider the voltage drop based on the distance of the cable and suitable action like oversizing the cable needs to be considered. Most of the UPSs are designed for a maximum operating temperature of 40°C.

What temperature should a ups room be?

For maximum service life, plan the equipment room so that normal operating temperatures are between 25-35°C. The UPS room should be relatively free of dust and dirt and other airborne contaminates as heavy layers of dust will reduce the cooling efficiency of the electronic components.

Does the size of ups differ between internal and external batteries?

Note#2: dimension of UPS can differ between the one with internal batteries and the one with external batteries. But the dimensions will not differ for the ones with internal batteries even if the number of internal battery strings changes as shown in below table-2. UPS output disconnecting device.

Learn More

- About UPS lithium battery site cabinet

- Emergency Battery Cabinet Standard

- Irish UPS battery cabinet manufacturer

- How to choose the main incoming wind power of UPS battery cabinet

- Can I open the battery cabinet after the UPS is turned off

- UPS battery cabinet rack weight

- UPS battery cabinet battery quantity

- UPS battery cabinet processing manufacturer

- How to determine the support frame of UPS battery cabinet

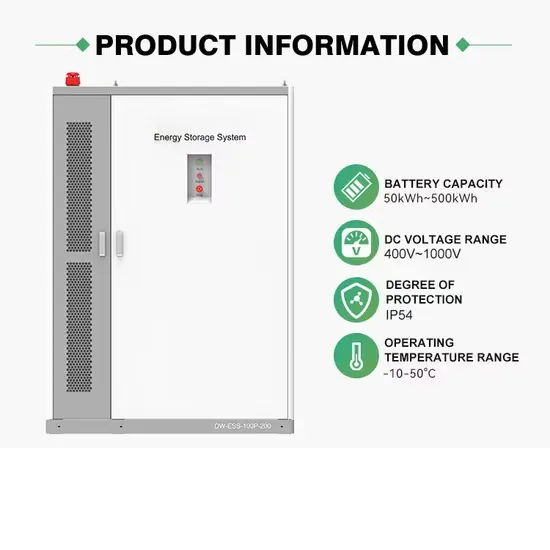

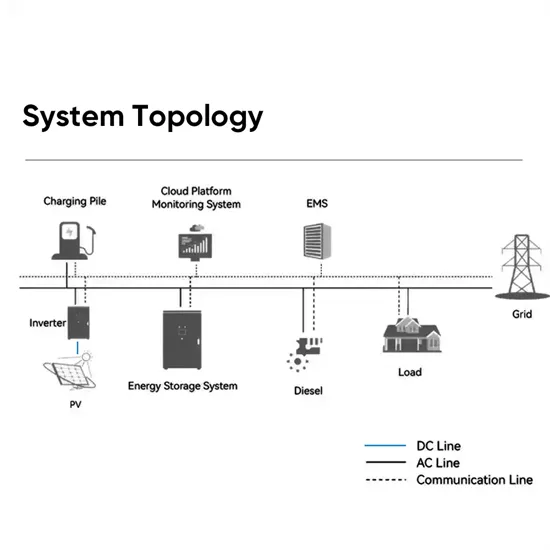

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

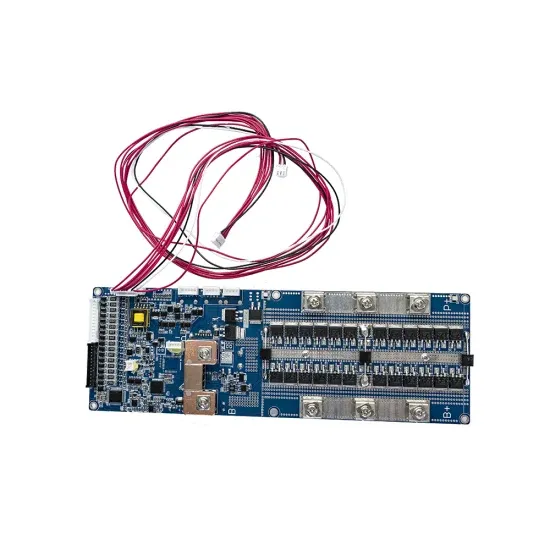

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.