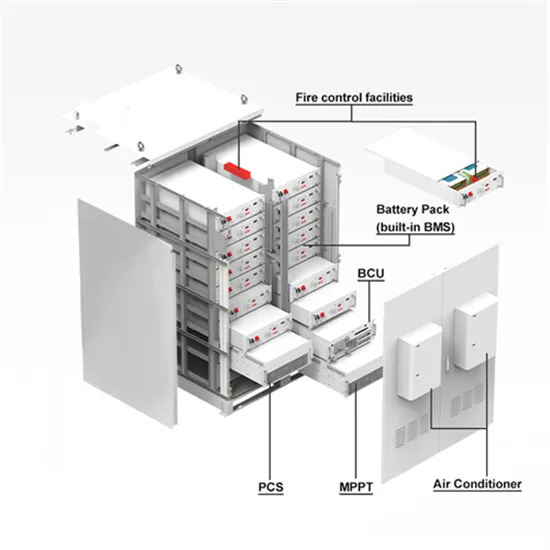

Structural composition of energy storage cabinet

The battery energy storage system is installed in a container-type structure, with built-in monitoring system, automatic fire protection system, temperature control system, energy

Battle for the EV Battery Box

Mar 17, 2023 · Aluminum battery enclosures typically deliver a weight savings of 40% compared to an equivalent steel design. According to Asfeth, the alloys best suited for battery enclosures

Constellium aluminum EV battery enclosures

Feb 19, 2021 · Aluminum is the dominant material for electric vehicle (EV) battery enclosures for one simple but significant factor: lightweighting capability. All

Battery Cabinet Aluminum Frames | HuiJue Group E-Site

The answer often lies in battery cabinet aluminum frames, which account for 68% of high-performance energy storage systems globally. But what exactly makes aluminum the material

Aluminum Battery Enclosure Design

Feb 11, 2021 · Aluminum as sheet and extruded profiles is the preferred material for BEV body structure, closures and battery enclosures. Aluminum battery enclosures or other platform

Why Aluminum Alloy is Revolutionizing Energy Storage Battery

Enter aluminum alloy for energy storage battery boxes, the unsung hero quietly transforming how we store solar and wind energy. The global energy storage market, valued at $33 billion [2],

Aluminum Battery Enclosure Design

Feb 11, 2021 · Historically high battery cost ($/kWh) and low storage density (Wh/kg) made value of light weight construction obvious = savings just from downsized battery packs easily paid for

The Difference Between Steel-shell, Aluminum

Nov 10, 2020 · The shell materials used in lithium batteries on the market can be roughly divided into three types: steel shell, aluminum shell and pouch cell

Aluminum-ion battery outperforms lithium

Feb 3, 2025 · Retains capacity after thousands of cycles with improved safety, sustainability, and affordability. Researchers have developed an aluminum-ion battery that outperforms lithium

Application and process analysis of aluminum alloy in new energy

Apr 25, 2025 · With the rapid development of new energy vehicles and energy storage industries, lightweight, high safety and efficient thermal management have become core demands. Our

Aluminum Alloy for New Energy Power Battery Case Market

Mar 21, 2025 · Aluminum alloy suppliers for new energy vehicle (NEV) power battery cases face **intensifying cost pressures** driven by volatile raw material prices, energy-intensive

Energy Storage Battery Pack Enclosure size optimization and

May 9, 2025 · In-depth analysis of ESS Battery Enclosure size matching and compatibility optimization technology, covering large-capacity battery cells, CTP integration, liquid cooling

Battery aluminum tray, aluminum for new energy vehicles

Oct 25, 2022 · Among them, the body includes a body frame made of high-performance aluminum profiles and skins and doors made of high-precision aluminum sheets; aluminum alloy wheels

6 FAQs about [Is the new energy battery cabinet made of aluminum alloy ]

Are aluminum battery enclosures a good choice?

Aluminum battery enclosures typically deliver a weight savings of 40% compared to an equivalent steel design. According to Asfeth, the alloys best suited for battery enclosures are the 6000-series Al-Si-Mg-Cu family — alloys that are also highly compatible with end-of-life recycling, he said.

What are energy power battery shells made of?

The new energy power battery shells on the market are mainly square in shape, usually made of 3003 aluminum alloy using hot rolled deep drawing process. Depending on the design requirements of the power battery, the thickness and width can be customized.

Are aluminum battery enclosures recyclable?

Aluminum battery enclosures or other platform parts typically gives a weight saving of 40% compared to an equivalent steel design. Aluminum is infinitely recyclable with zero loss of properties. At end of life 96% of automotive aluminum content is recycled. Recycling aluminum only requires 5% of the energy needed for primary production.

What material is used in power battery aluminum trays?

Chalco's production of power battery aluminum trays mostly uses 6-series 6061 aluminum plate as the raw material for battery aluminum trays, which can meet the characteristics of high precision, corrosion resistance, high temperature resistance, and impact resistance to protect the battery core.

Which aluminum alloy is used in power batteries?

Aluminum alloy is a commonly used material for power batteries, and there is an urgent need to focus on research, development, and upgrading of products and alloy materials. At present, the conventional aluminum alloys used in power batteries mainly include 1-series, 3-series, 5-series, and 6-series.

What are the advantages of aluminum frame & aluminum plate structure battery shell?

The aluminum alloy frame and aluminum plate structure battery shell have flexible structural design, obvious weight reduction and mature technology. The extruded aluminum frame can provide high rigidity and high strength, and the aluminum plate stamping parts are sealed.

Learn More

- New Energy Battery Cabinet 372KWh

- New Energy Battery Cabinet Base Station Energy Equipment

- New Energy Battery Cabinet Project Address

- New Energy Retrofit Battery Cabinet

- How thick is the armor of the new energy battery cabinet

- New energy battery cabinet fixing plate

- Kuwait City New Energy Battery Cabinet Professional Communication Power Supply

- Kigali New Energy Battery Cabinet Base Station Power Generation Store

- New Energy Battery Cabinet Test Standards

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.