How to Assemble a Lithium-Ion Battery Pack

Oct 7, 2024 · In this guide, we provide step-by-step instructions, tips, and safety precautions to help you assemble a reliable battery pack with a BMS module,

From Raw Materials to Finished Product: The

Nov 10, 2024 · From obtaining raw lithium brine and extracting and purifying raw material to manufacturing and testing Li-ion cells to assembling the cells and

How Are Lithium Battery Packs Assembled?

Aug 18, 2025 · By following the key steps involved in lithium battery pack assembly, including cell selection and testing, cell arrangement and connection, BMS integration, and final assembly

Mastering the Art of Lithium Battery Pack

May 1, 2023 · Join me on an adventure into the fascinating world of lithium battery pack assembly. As we explore the intricate craft of assembling these powerful

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this step-by-step

Spot Welding vs Soldering Lithium Batteries Explained

May 17, 2025 · Understand the difference between spot welding and soldering lithium batteries, including their applications, advantages, and limitations for battery assembly.

How to Build a Lithium Battery: Step-by-Step for Beginners

Feb 22, 2024 · Before assembling the lithium battery pack, you need to check whether the lithium battery cell and the protective circuit board are intact and ensure that their specifications and

What are lithium ion batteries

Jul 9, 2025 · 🔋 Lithium-ion batteries have revolutionized the way we power our lives, from smartphones and laptops to electric vehicles and off-grid solar systems. However, when you

Lítium akkumulátorok ponthegesztéshez kockázat nélkül

Jun 27, 2025 · Spot welding is a crucial aspect of battery technology, particularly when learning how to spot weld lithium batteries for assembling reliable battery packs. This precise technique

Methods and precautions for lithium battery

Jan 29, 2024 · Li-ion battery is a high energy density battery which is widely used in mobile electronic devices, electric vehicles and energy storage systems,

Assembling and Testing Lithium-ion Battery

Jan 25, 2025 · Assembling a lithium-ion battery pack is a meticulous process that requires careful planning and precise execution. It involves several critical

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · CMB''s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium),

Beginner-Friendly Tips for Assembling Lithium Battery Packs

May 7, 2025 · Effective planning lays the foundation for a reliable lithium battery pack. You should start by defining the application requirements, such as voltage, capacity, and size constraints.

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

Jun 15, 2025 · In this step-by-step guide, as a professional lithium battery pack manufacturer, I''ll walk you through the entire DIY battery pack assembly process to help you build a safe, high

How to Build Your Own Battery Pack: A Step-by-Step Guide

Feb 21, 2025 · Building your own battery pack can be an exciting and rewarding project, allowing you to customize power solutions for various applications, from electric bikes to solar energy

How to Build Your Own Battery Pack

Apr 5, 2025 · Building your own battery pack is a rewarding project that allows you to create a customized power source for various devices, from electric vehicles to solar setups. Whether

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · The paper analyzes the design practices for Li-ion battery packs employed in applications such as battery vehicles and similar energy storage systems. Twenty years ago,

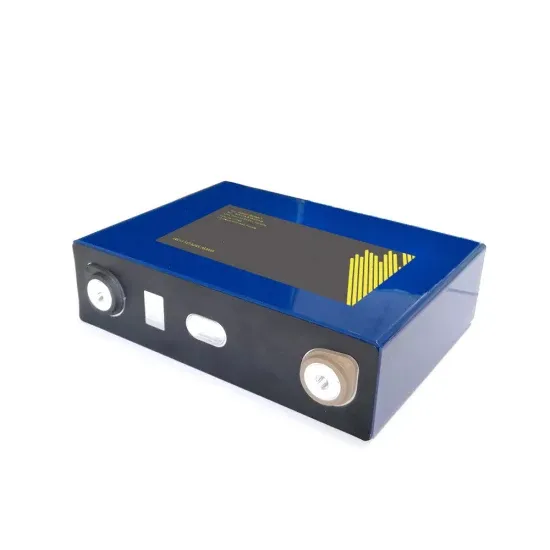

Factory Price LTO 12V 30Ah 35Ah 40Ah 45Ah 6S1P Battery

Acrylic Case 12V 40Ah LTO Lithium Titanate Battery Yinlong 66160 6S1P LTO 30ah 35ah 40Ah 45ah Battery for Car Audio The LTO battery is the most safety lithium battery at present will

Methods and precautions for assembling lithium batteries

3. Avoid short circuits: Short circuits in lithium batteries can cause excessive current, leading to fires and explosions. Therefore, when assembling and using lithium batteries, metal or

Efficient Battery Module Assembly Platform: Automated Lithium

Discover our state-of-the-art Battery Module Assembly Platform designed for efficient and precise lithium-ion battery module production. Suitable for manual, semi-automated, or fully automated

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Diferent shapes of the lithium-ion cell Nomenclature of lithium-ion cell/battery Overview of Li-ion battery packs Assembling Process Detailed flowchart for Li-ion battery pack

How to Build a LiFePO4 Battery Pack: A Step-by-Step Guide

3 days ago · Build a custom LiFePO4 battery pack safely. This guide provides step-by-step instructions on wiring, BMS installation, and pro tips for performance and longevity. Ideal for

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Each phase plays a critical role in ensuring the performance, safety, and reliability of the battery module. With proper attention to quality and

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Among various energy storage technologies, lithium-ion battery packs have emerged as the preferred choice due to their high energy density, long cycle life, and

6 FAQs about [Lithium battery suitable for assembling battery packs]

What is a high-performance lithium battery pack?

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the heart of this burgeoning industry lies a meticulously orchestrated assembly process, where individual lithium-ion cells are transformed into powerful energy storage systems.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

Which battery cells are used in a CMB battery pack?

CMB’s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium), LFP (Lithium Iron Phosphate Chemistry) and LiPo (Lithium Polymer).

Why is quality control important in a lithium battery pack assembly?

Consequently, this intricate step paves the way for efficient power transfer and optimal pack performance. Quality control is a cornerstone of the lithium battery pack assembly process.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

Learn More

- Do lithium battery packs need additional containers

- Suitable for iron anchor tool lithium battery

- How many lithium battery packs are needed for 60v

- Lithium batteries are divided into cells and battery packs

- The voltage of several lithium battery packs is consistent

- Equipment needed to process lithium battery packs

- Processing various types of lithium battery packs

- Reference price of good lithium battery packs in Southern Europe

- 42 lithium battery packs in 14 strings

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.