Which battery is better for power tools?-Product News-Power Tool

Jul 28, 2022 · At present, the technology of lithium iron phosphate batteries is insufficient compared with nickel-hydrogen batteries, so the battery consistency is relatively poor, and the

Charging Lithium Batteries with Alternator: A

Aug 16, 2025 · Understanding Alternators and Lithium Batteries Before we dive into the details of charging lithium batteries with an alternator, let''s first

Iron Anchor Lithium Battery Brushless Electric Hammer Drill

Aug 20, 2024 · Iron anchor lithium battery brushless dual-purpose light home improvement impact drill - Anchor Impact Drill, Electric Drill, Drill Hole Electric Hammer Q: What is the voltage of

Deployment strategies for Li-rich cathode materials in batteries

Jun 23, 2025 · Lithium-rich cathode materials face challenges due to the irreversibility of redox processes at high voltages, limiting their practical use. However, their significant potential is

Chinese Battery + PCM + Charger supplier | YUNTONG

Li-ion Battery, Suitable for GPS, PDA, and Power Tool Charger, 7.4V Suitable for 2S LiFePO4 Battery Charger for 6 to 10 Cells Ni-MH/Ni-CD Battery Pack, 0.9A or 1.8A Adjustable Charge

How To Choose A Power Tool Battery?

Aug 4, 2025 · Lithium iron phosphate batteries for power tool batteries have certain advantages, and their high-temperature resistance is better than other types of lithium-ion batteries. At the

Anchor anchor anji 16.8v brushless lithium electric drill dce8

For home decoration, diy crafts, and furniture installations, you can never live without a reliable electric drill! anchor iron anchor''s 16.8v brushless lithium electric drill dce8 is really the most

Expert Solutions for Efficient and Reliable anchor battery

About anchor battery In the realm of modern construction and home improvement, anchor battery have become indispensable tools. These power-driven devices are designed to drill holes or

Lithium Iron Phosphate Battery Packs: Powering the Future

Apr 22, 2025 · 1. Introduction In the dynamic landscape of energy storage technologies, lithium - iron - phosphate (LiFePO₄) battery packs have emerged as a game - changing solution.

Iron Anchor Electric Hammer | Lithium Battery Heavy-Duty

Mar 9, 2025 · Iron anchor lithium battery heavy duty brushless rechargeable handheld impact drill - Anchor Impact Drill, Electric Pick, Anchor Electric Hammer Q: Is the Iron Anchor Electric

Exploring sustainable lithium iron phosphate cathodes for Li

Lithium iron phosphate (LFP) cathodes are gaining popularity because of their safety features, long lifespan, and the availability of raw materials. Understanding the supply chain from mine

Fe, N co-doped graphene as a multi-functional anchor

Mar 1, 2019 · Abstract Application of lithium-sulfur battery is still hindered by the poor cycling life, rapid capacity decay and severe self-discharge, which are mainly caused by the well-known

How to Choose the Right Lithium-Ion Battery-Powered Power Tools?

Lithium-lon Battery-Powered Power Tools have become mainstream in modern industrial, construction, and home improvement sectors due to their exceptional portability, high

Lithium Battery Storage & Charging Cabinets

Battery storage cabinet, ideal for storing small lithium batteries as used in devices such as power tools. Sturdy unit is manufactured with heat-insulating, double walled steel, and features a

6 FAQs about [Suitable for iron anchor tool lithium battery]

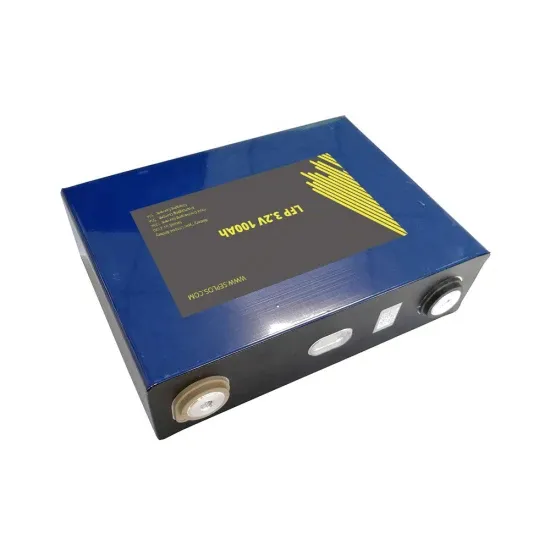

What are the advantages of lithium iron phosphate batteries for power tool batteries?

Lithium iron phosphate batteries for power tool batteries have certain advantages, and their high-temperature resistance is better than other types of lithium-ion batteries. At the same time, it can achieve discharge performance above the 30C rate. It has ideal results when used in normal and wide-temperature environments.

What is a lithium ion battery used for?

As an energy storage device integrating high energy density and high voltage, lithium-ion batteries have been widely used in mobile and wireless electronic equipment, power tools, hybrid and electric vehicles and other fields. What types of power tool batteries are there?

What are the different types of power tool batteries?

There are many types of power tool batteries, with lithium-ion (Li-ion) batteries being the most common because of their high energy density, long life and light weight. They are critical for construction, carpentry and home improvement work. How To Choose A Power Tool Battery?

Do power tool batteries meet high rate discharge performance?

If the power tool battery is made of ordinary lithium-ion battery, it must meet the high-rate discharge performance to meet the working requirements of the power tool. However, ordinary lithium-ion batteries cannot achieve higher rate discharge performance due to cost and material limitations.

What are the disadvantages of lithium iron phosphate batteries?

At present, the technology of lithium iron phosphate batteries is somewhat inadequate compared with nickel-metal hydride batteries, the consistency of the batteries is relatively poor, and the safety of the battery pack is slightly worse than that of nickel-metal hydride batteries.

Which power tool battery is the most expensive?

Among power tool batteries, polymer lithium-ion batteries should be the most expensive. Polymer lithium-ion batteries are not only higher in energy density but also the best in achieving ultra-high rate discharge performance.

Learn More

- Lithium iron phosphate tool battery

- Rwanda lithium iron phosphate battery pack

- What is the actual life of a 60v lithium iron phosphate battery pack

- Imported lithium iron phosphate battery pack

- Syria cylindrical lithium iron phosphate battery

- 60kwh lithium iron phosphate battery pack price

- Liquid-cooled energy storage lithium iron phosphate battery station cabinet

- Zhongya lithium iron phosphate battery pack customization

- 280ah lithium iron phosphate energy storage battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.