Are Battery Packs Lithium? Explore Portable Chargers, Safety,

Dec 27, 2024 · Most battery packs, especially portable chargers, use lithium-ion batteries. These batteries are efficient and lightweight, which suits portable devices.

2021 Lithium Battery Guidance Document

Dec 16, 2020 · The provisions of the DGR with respect to lithium batteries may also be found in the IATA lithium Battery Shipping Guidelines (LBSG) 8th Edition. In addition to the content

Lithium Battery Storage Container Market

Aug 30, 2024 · The lithium battery storage container market is experiencing accelerated growth driven by several key factors. The increasing integration of renewable energy sources into

What is the difference between storage and transportation containers

There are currently no comparable regulations for storage. Nevertheless, manufacturers of storage boxes regularly carry out appropriate tests. The right container depends on the type

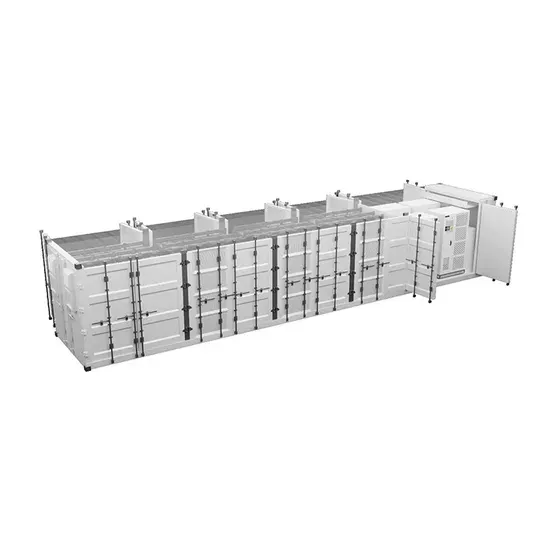

Designing a BESS Container: A Comprehensive Guide to Battery

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

Battery Transportation Requirements

For example, lithium batteries must be packaged in a strong, rigid outer packaging that is resistant to damage during transport. The packages must also be marked with specific labels and

Guide to Shipping Batteries Overseas by Air and

Sep 28, 2022 · This guide has been written to address this issue and give clear and correct advice about sending lithium and lithium-ion batteries abroad no

Detailed Understanding of the Containerized Battery System

Dec 13, 2024 · The containerized battery system has become a key component of contemporary energy storage solutions as the need for renewable energy sources increases. This system is

Lithium Battery Packaging: A Comprehensive Guide to Safe

Jul 9, 2025 · Without proper packaging, lithium-ion batteries can short-circuit, overheat, or leak hazardous materials. That''s why certified, purpose-built packaging solutions are necessary to

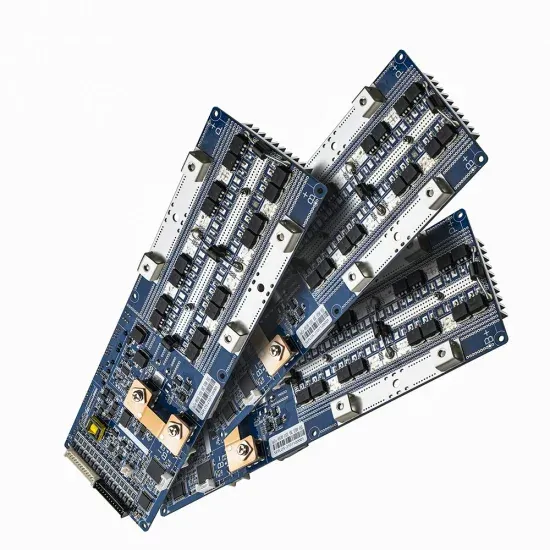

How Do Lithium-Ion Battery Packs Function?

Feb 26, 2025 · Lithium-ion battery packs work by moving lithium ions between the anode and cathode, generating energy to power devices like smartphones and electric vehicles.

What Are Lithium Battery Storage Containers and Why Are

Apr 11, 2025 · Lithium battery storage containers are specialized units designed to safely store and manage lithium-ion batteries, mitigating risks like thermal runaway, fires, and explosions.

University of Pennsylvania

Jul 25, 2024 · 1.0 Purpose and Applicability 1.1 It is the policy of the University of Pennsylvania in coordination with the Office of Environmental Health and Radiation Safety to provide the

Revolutionizing Lithium Battery Transport: Exploring

Sep 26, 2024 · Battery Module Packs The rapid shift toward electrification across industries has led to a surge in the use of lithium-ion batteries. These batteries are vital for powering a wide

Lithium battery transport: all you need to know

Dec 20, 2022 · The growing demand for electrification has led to the introduction of regulations, classifications and certifications for lithium battery transport.

6 FAQs about [Do lithium battery packs need additional containers ]

What are the requirements for packaging a lithium battery?

These regulations specify the type of packaging that must be used, as well as the labeling, documentation, and handling requirements that must be followed. For example, lithium batteries must be packaged in a strong, rigid outer packaging that is resistant to damage during transport.

How to pack a lithium battery?

Always pack lithium batteries as per IATA and DOT regulations. Good packing lowers risks and follows safety rules. Keep correct paperwork for all lithium battery shipments. This avoids fines and keeps things running smoothly.

What are the regulations for storing lithium batteries?

These regulations depend on the size (watt hour) of the battery and condition of the battery (damaged vs. non-damaged). Storing lithium batteries presents unique challenges because there are both national regulations and unique ordinances to follow, while some countries don’t have specific rules for them.

How do I identify a lithium battery hazardous goods container?

Except for vehicles driven by lithium batteries (pure electric or hybrid), containers containing lithium battery hazardous goods must have Class 9 hazardous goods labels and UN number markings affixed to each side and each end of the container (for lithium-ion battery energy storage systems, on two opposite sides).

Are lithium batteries safe to ship?

There are very specific regulations that govern the proper packaging of lithium batteries for shipping. These regulations are in place to ensure the safe transportation of lithium batteries and to minimize the risk of fire or explosion during transport.

How to transport a lithium battery safely?

Proper packaging, labeling, and compliance with regulations are crucial for safe lithium battery transport. Trust Epec’s expertise for a hassle-free, compliant solution. Lithium-ion and lithium polymer cells and both non-rechargeable and rechargeable battery packs need to be managed to ensure safety during transportation.

Learn More

- Do lithium battery packs need voltage division

- How many watts of inverter do I need for a 20A lithium battery

- Where to buy lithium battery packs in Izmir Türkiye

- How many amperes are there in 40 lithium battery packs of 36v

- The voltage of several lithium battery packs is consistent

- Lithium batteries are divided into cells and battery packs

- Where to assemble lithium battery packs in Macedonia

- Power lithium battery packs can be mixed

- How many strings are there of 21 volt lithium battery packs

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.