Lithium Battery Basics: A Crash Course

Apr 29, 2021 · When several cells are put together in a single structure, they make up a battery module (or pack). As mentioned above, a cell normally has a voltage of around 3-4V, but

What are The Differences Between Fixed Capacity and

Mar 27, 2025 · In the lithium battery production process, "capacity determination" and "capacity division" are two crucial links, especially playing a decisive role in the performance and

LFP Vs Lithium Ion: Pros And Cons?

May 26, 2025 · LFP (Lithium Iron Phosphate) batteries prioritize safety and longevity with stable thermal performance, ideal for stationary storage and EVs requiring frequent cycling.

Battery Management System Voltage Division

Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically organized in a row x column matrix

Understanding the Relationship Between Lithium-ion Cells and Battery Packs

Jul 11, 2025 · Technical Foundations: How Lithium-ion Cells Form a Battery Pack. Series Connection: Increases voltage (e.g., 4S1P = 4 cells in series, 1 parallel group). Parallel

2022 Lithium Battery Guidance Document

3 days ago · Lithium-ion batteries (sometimes abbreviated Li-ion batteries) are a secondary (rechargeable) battery where the lithium is only present in an ionic form in the electrolyte. Also

Custom Lithium Ion Battery Packs vs Off-the-Shelf: What Engineers Need

Jul 21, 2025 · Development timelines represent a critical design parameter when selecting between . custom lithium ion battery packs and off-the-shelf solutions. Standard battery packs

Helpful Guide to Lithium Batteries in Parallel and

Apr 23, 2024 · In actual use, lithium batteries need to be combined in parallel and series to obtain a lithium battery pack with a higher voltage and capacity to

How Do Lithium-Ion Battery Packs Function?

Feb 26, 2025 · Lithium-ion battery packs work by moving lithium ions between the anode and cathode, generating energy to power devices like smartphones and electric vehicles.

Introduction: What Is a Lithium-Ion Battery Pack?

Jul 4, 2025 · Learn the differences between 18650, 21700, and custom lithium-ion battery packs. Understand voltages like 11.1V and 14.8V, and how to choose the right Li-ion battery pack for

Do Lithium Batteries Need a Management System (BMS)?

May 15, 2024 · Most of the time, it is used for 3.7V or 7.4V battery packs, it has four basic functions: overcharge, overdischarge, overcurrent and short circuit. Some batteries may also

What is the meaning of Li-ion battery capacity division?

Lithium battery capacity division is an adjustment method for lithium-ion battery packs, mainly to solve the problems caused by the difference in electrical performance of the single cells in the

Do You Need Fuse Wire for Lithium Battery Packs? Safety,

Apr 18, 2025 · In conclusion, when selecting a fuse wire for lithium battery packs, factor in the battery''s maximum current output, the type of fuse, and environmental conditions.

Lithium Series, Parallel and Series and Parallel

Mar 23, 2021 · 1. What is a BMS? Why do you need a BMS in your lithium battery? The primary function of a BMS is to ensure that each cell in the battery remains within its safe operating

The Ultimate Guide to Lithium Battery Packs: Everything You Need

Feb 14, 2025 · Lithium battery packs have become an indispensable part of modern life, powering everything from smartphones to electric vehicles. Their lightweight, high energy density, and

Battery guidance document

Feb 3, 2025 · • UN 3090, lithium metal batteries prepared in accordance with PI 968 and • UN 3480, lithium-ion batteries prepared in accordance with PI 965, and • UN 3551, sodium ion

Lithium Rechargeable Batteries – IBEX Resources

Good Resources Battery University Lithium Cell Voltage 3.0 to 4.2V (cell voltage typically specified as 3.7V) Series battery packs: 2 cells in series: 6.0 to 8.4V (7.4V typ) 3 cells in

SOC Estimation of Lithium-Ion Battery Pack Based on

Mar 19, 2025 · To meet practical usage requirements, lithium-ion batteries usually need to form a battery pack. However, due to production deviations and different usage environments, there

6 FAQs about [Do lithium battery packs need voltage division ]

Why do lithium ion batteries need to be connected in series?

To meet the power and energy requirements of the specific applications, lithium-ion battery cells often need to be connected in series to boost voltage and in parallel to add capacity . However, as cell performance varies from one to another [2, 3], imbalances occur in both series and parallel connections.

Do lithium-ion batteries need a battery pack?

To meet practical usage requirements, lithium-ion batteries usually need to form a battery pack. However, due to production deviations and different usage environments, there are inconsistencies between batteries within the battery pack. This makes it challenging to estimate the state of charge (SOC) of the battery pack accurately.

What is the nominal voltage of a lithium ion battery?

The nominal voltage is the average voltage during a discharge. Normally, the cell voltage for lithium-ion batteries is around three to four volts (V). Several cells, therefore, are needed to form a pack to achieve the voltage required for a certain application, for instance, 48 V.

What happens if a battery pack is in series?

For components in series, the current through each is equal and the voltage drops off. In a simple model, the total capacity of a battery pack with cells in series and parallel is the complement to this.

How is cell voltage determined in a lithium ion battery?

The cell voltage is determined by its two electrodes: the negative (anode) and the positive electrode (cathode). The nominal voltage is the average voltage during a discharge. Normally, the cell voltage for lithium-ion batteries is around three to four volts (V).

Why do lithium batteries need balancing?

When several lithium cells are connected in series, it is the variation between series sections that requires balancing to be used. The problem with leakage and charge efficiency is that differences in these have a cummulative effect, and battery imbalance grows with each charge/discharge cycle.

Learn More

- Do lithium battery packs need additional containers

- The voltage of several lithium battery packs is consistent

- Lithium battery pack fast charging voltage

- Lithium battery pack 1000V high voltage charging and discharging

- 42 lithium battery packs in 14 strings

- How fast is considered fast charging for lithium battery packs

- Full-charge voltage of lithium battery pack

- Equipment needed to process lithium battery packs

- How many amperes are there in 40 lithium battery packs of 36v

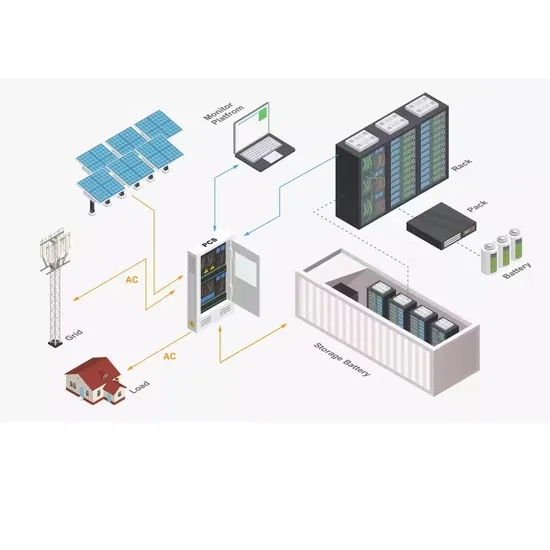

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.