Lithium Series, Parallel and Series and Parallel

Mar 23, 2021 · Lithium Series, Parallel and Series and Parallel Connections Introduction Lithium battery banks using batteries with built-in Battery Management Systems (BMS) are created by

How to check the number of strings and parallels of new energy batteries

How many strings are 48V20AH lithium battery packs? How to calculate how many strings and parallels are needed for a set of lithium batteries Therefore, the lithium battery must also be

How to check the number of strings and parallels of new energy batteries

How to calculate how many strings and parallels are needed for a set of lithium batteries Therefore, the lithium battery must also be about 58v, so it must be 14 strings to 58.8v, 14

16 strings of lithium iron phosphate batteries placed

How many cells are in a set of lithium iron phosphate batteries? The whole set of batteries is 14 strings multiplied by 10 cells = 140 cells. Summary: Series and parallel have their own

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However,

How Many Cells in a Lithium Battery Pack? A Complete

Mar 14, 2025 · Lithium batteries use multiple cells. For example, a lithium-ion battery has 3 cells for 11.1 volts, 4 cells for 14.8 volts, or 10 cells for 37 volts. Cells can be arranged in series to

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

How many strings of lithium iron phosphate batteries

The whole set of batteries is 14 strings multiplied by 10 cells = 140 cells. Summary: Series and parallel have their own advantages for lithium iron phosphate batteries. Series and parallel

A New Equalization Method for Lithium-Ion Battery Packs

May 21, 2024 · With the rapid development of society, people''s demand for energy is increasing, and all walks of life around the world are gradually transforming into low-carbon [1 – 5]. Lithium

Consistency evaluation of Lithium-ion battery packs in

Dec 20, 2024 · During the service process of lithium-ion battery packs, there is inconsistency among the cells in the pack, resulting in a significant decline in bat

State of Charge Imbalance Classification of Lithium-ion

Oct 2, 2022 · New York, NY, USA agl2142@columbia Abstract—Lithium-ion battery strings are important modules in battery packs. Due to cel. variation, strings may have im-balanced

基于可重构电路的串联电池动态分组主动均衡方法-《郑州大学

Mar 10, 2025 · LI J B, MENG H J, PI Z J, et al. Application status and development trends of the lithium primary batteries [J]. Chinese Journal of Power Sources, 2018, 42 (5): 725-727.

How many strings of 24V lithium iron phosphate batteries

How many cells are in a set of lithium iron phosphate batteries? The whole set of batteries is 14 strings multiplied by 10 cells = 140 cells. Summary: Series and parallel have their own

Cell-balancing currents in parallel strings of a battery system

Jul 30, 2016 · Lithium-ion batteries are attractive for vehicle electrification or grid modernization applications. In these applications, battery packs are required to have multiple-cell

Cell-balancing currents in parallel strings of a battery system

Jul 30, 2016 · Reliability and safety are important and timely issues for lithium-ion batteries [1] that shall be addressed by stakeholders in all sectors where large battery packs are required to

A novel active equalization method for lithium-ion batteries

May 1, 2015 · Therefore, cell equalization is essentially required. In this paper, we propose a novel active equalization method based on the remaining capacity of cells which is feasible for

A Novel Active Cell Balancing Approach Based on

Oct 2, 2024 · In recent years, the advancements in deep reinforcement learning (DRL) have made it a viable tool for battery management systems (BMS) in EV''s. In this research paper, a new

How many strings are there of 42 lithium batteries

Therefore, the lithium battery must also be about 58v, so it must be 14 strings to 58.8v, 14 times 4.2, and the iron-lithium battery is fully charged to about 3.4v, four strings must...

Onlin free battery calculator for any kind of battery : lithium

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Calculate the number of series and parallel connections for lithium

May 19, 2024 · Series parallel connection of lithium batteries is particularly common in some PACK factories. Generally, lithium battery packs are composed of batteries in series parallel

State of Charge Imbalance Classification of Lithium-ion

Oct 2, 2022 · Abstract—Lithium-ion battery strings are important modules in battery packs. Due to cell variation, strings may have im-balanced state of charge levels, reducing pack capacity and

42 lithium battery packs in 14 strings

Abstract—Lithium-ion battery strings are important modules in battery packs. Due to cell variation, strings may have im-balanced state of charge levels, reducing pack capacity and exacerbating

State-of-charge estimation and uncertainty for lithium-ion battery strings

Apr 15, 2014 · Some earlier discussions on merits and drawbacks of various methods for SOC estimation, primarily for lead-acid battery packs, are already in the literature [14].

How many strings are 48V20AH lithium battery

Mar 3, 2021 · The whole set of batteries is 14 strings multiplied by 10 cells = 140 cells. Summary: Series and parallel have their own advantages for lithium iron

(PDF) Equalization circuit topologies of lithium battery strings

Sep 1, 2020 · Lithium batteries are widely applied in new energy vehicles and related energy storage industries due to their superior performance. The application of an equalization circuit

Optimal fast charging strategy for series-parallel configured lithium

Jan 1, 2025 · The limited charging performance of lithium-ion battery (LIB) packs has hindered the widespread adoption of electric vehicles (EVs), due to the complex arrangement of numerous

Few-shot fault diagnosis for lithium-ion battery packs based

Apr 15, 2025 · Therefore, precisely diagnosing faults within lithium-ion battery packs, especially in scenarios where fault data is limited (few-shot conditions), is a crucial challenge that is vital for

Battery Pack Calculator | Good Calculators

Battery Pack Calculator Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and

基于充电电压的串联电池组早期多故障诊断

Dec 10, 2023 · The timely detection and accurate identification of various fault types in battery packs are critical to the safe operation of electric vehicles and

6 FAQs about [42 lithium battery packs in 14 strings]

How many strings should a lithium battery have?

Therefore, the lithium battery must also be about 58v, so it must be 14 strings to 58.8v, 14 times 4.2, and the iron-lithium full charge is about 3.4v, it must be four strings of 12v, 48v must be 16 strings, and so on, 60v There must be 20 strings in parallel with the same model and the same capacity.

How many lithium batteries can be connected in series?

Lithium battery pack 48V20AH generally single lithium battery is 3.5V, so 48V lithium battery pack needs 48/3.5=13.7, just take 14 in series. If the manufacturer has provided a set of 12V lithium batteries, then 4 can be connected in series. As long as the output voltage is 48V, the current is 2A or 4A.

Can a lithium ion battery pack have multiple strings?

Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However, sometimes it may be necessary to use multiple strings of cells. Here are a few reasons that parallel strings may be necessary:

How many cells are in a set of lithium iron phosphate batteries?

The whole set of batteries is 14 strings multiplied by 10 cells = 140 cells. Summary: Series and parallel have their own advantages for lithium iron phosphate batteries. Series and parallel lithium battery packs have different methods and achieve different goals.

What are the different types of lithium battery packs?

Lithium battery series and parallel: There are both parallel and series combinations in the middle of the battery pack, which increases the voltage and increases the capacity. Such as 4000mAh, 6000mAh, 8000mAh, 5Ah, 10Ah, 20Ah, 30Ah, 50Ah, 100Ah and so on. Take 48V 20Ah lithium battery pack as an example Lithium Battery PACK

What is lithium iron phosphate battery pack?

When lithium iron phosphate battery packs are assembled, different capacities and different voltages are generally realized in parallel or in series. In the lithium battery pack, multiple lithium batteries are connected in series to obtain the required operating voltage.

Learn More

- How many strings are there of 21 volt lithium battery packs

- How many amperes are there in 40 lithium battery packs of 36v

- Power lithium battery packs can be mixed

- Lithium batteries are divided into cells and battery packs

- The voltage of one of the lithium battery strings is low

- Do lithium battery packs need additional containers

- 5 12v lithium battery packs

- How fast is considered fast charging for lithium battery packs

- Where to assemble lithium battery packs in Macedonia

Industrial & Commercial Energy Storage Market Growth

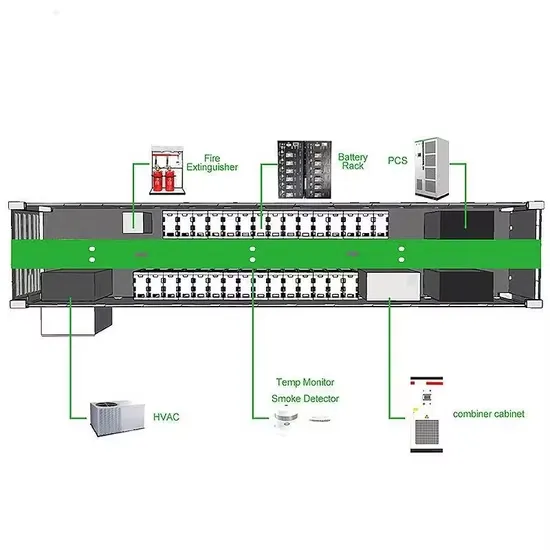

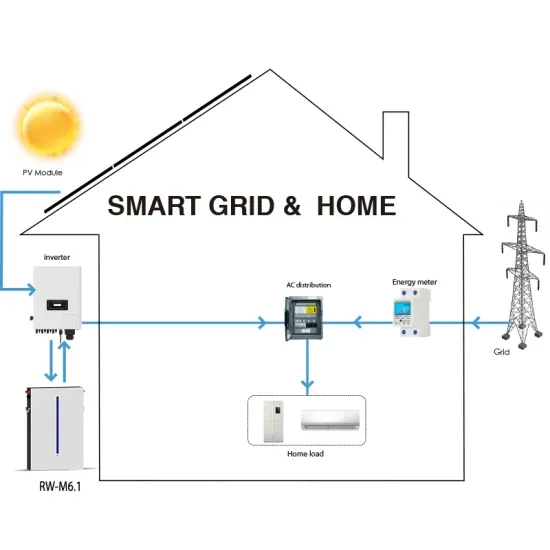

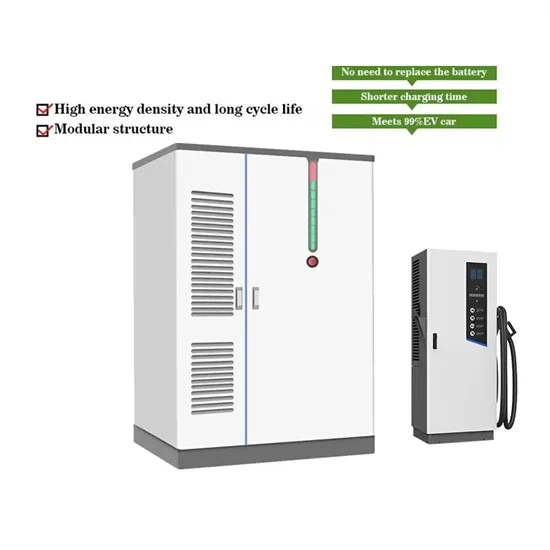

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.