Analysis of lithium battery voltage and its

2 days ago · In the initial phase of charging, the lithium battery voltage is usually low, and as the internal chemical reactions of the battery gradually reach

What voltage is too low for lithium battery?

The critical low-voltage threshold for lithium-ion batteries is 2.5V per cell, below which irreversible damage occurs due to copper dissolution and SEI layer breakdown. Discharging below

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · One multi-purpose output is used to signal if discharging must stop due to a low cell voltage, and the other output is used to stop charging due to a high cell voltage (in the

Lithium Battery Voltage Chart: 3.2V, 3.7V, 4.2V

Jan 4, 2024 · What is a Battery Voltage Chart? A battery voltage chart is a critical tool for understanding how different lithium-ion batteries perform under specific

Understanding Lithium Battery Low Voltage

Mar 4, 2025 · Conclusion Understanding low voltage cutoff in lithium batteries is crucial for anyone who relies on these energy storage solutions. By preventing

Common Lithium-ion Battery Problems and How

Nov 15, 2018 · If the voltage is below 2V, the internal structure of lithium battery will be damaged, and the battery life will be affected. Root cause 1: High self

Lithium Ion Battery Voltage Chart: A Comprehensive Guide

Jun 22, 2025 · Lithium-ion batteries are widely used in various applications, including electric vehicles, portable electronics, and renewable energy systems. One of the critical aspects of

White Paper on Active Current Balancing and Intelligent

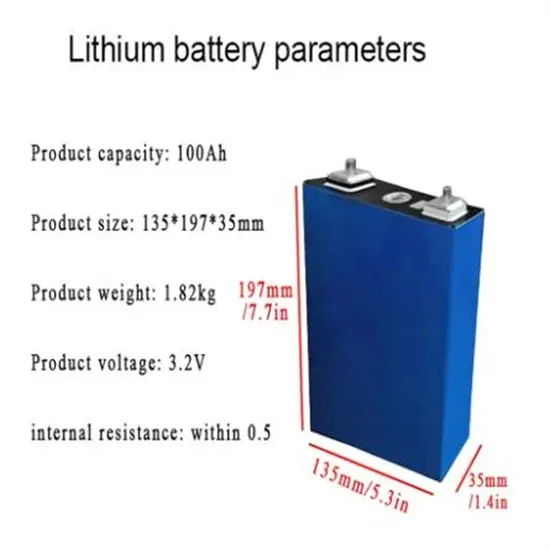

Dec 12, 2024 · The voltage of a single lithium-ion battery cell is low. If 3.2 V LFP cells are adopted, 160 cells need to be connected in series to provide the battery voltage of 512 V DC.

State-of-charge estimation and uncertainty for lithium-ion battery strings

Apr 15, 2014 · The state-of-charge (SOC) estimation is of extreme importance for the reliability and safety of battery operation. How to estimate SOC and, to some de

State of Charge Imbalance Classification of Lithium-ion

Oct 2, 2022 · Abstract—Lithium-ion battery strings are important modules in battery packs. Due to cell variation, strings may have im-balanced state of charge levels, reducing pack capacity and

White Paper on Active Current Balancing and Intelligent

Dec 10, 2024 · Although lithium-ion batteries have many advantages, challenges exist in actual application. This paper analyzes and describes voltage balancing management of lithium-ion

A Low Cost and Fast Cell-to-Cell Balancing Circuit for

Jan 14, 2024 · Abstract: This paper proposes a fast cell-to-cell balancing circuit for lithium-ion battery strings. The proposed method uses only one push-pull converter to transfer energy

What to do if the lithium battery voltage is low? What is the

If the voltage is low due to battery aging, you may need to consider replacing a new battery. For over-discharge, avoid similar behavior again and charge the battery in time to restore its voltage.

State of Charge Imbalance Classification of Lithium-ion

Oct 2, 2022 · I. INTRODUCTION hundred of cells [1]. For proper functioning, the battery management system (BMS) must monitor each individual cell. Typically the voltage, current,

Paper Title (use style: paper title)

Jan 13, 2024 · Constant current and constant voltage controller and fuzzy controller are designed and simulated to evaluate the charging time for series-connected lithium-ion batteries.

State-of-charge estimation and uncertainty for lithium-ion battery strings

Apr 15, 2014 · The most accurate method for SOC estimation in strings is the one similar to that used in the single cells based on the OCV = f (SOC) correspondence, based on

6 FAQs about [The voltage of one of the lithium battery strings is low]

What causes low voltage in a lithium battery?

Root cause 1: High self-discharge, which causes low voltage. Solution: Charge the bare lithium battery directly using the charger with over-voltage protection, but do not use universal charge. It could be quite dangerous. Root cause 2: Uneven current.

What happens if a lithium-ion battery reaches a low charge level?

When a lithium-ion battery reaches a low charge level, several consequences arise. Firstly, a noticeable voltage drop leads to diminished power output. This voltage drop affects the functionality of electronic devices powered by these batteries, often resulting in reduced performance or complete shutdown.

What should you know about lithium ion batteries?

The most important key parameter you should know in lithium-ion batteries is the nominal voltage. The standard operating voltage of the lithium-ion battery system is called the nominal voltage. For lithium-ion batteries, the nominal voltage is approximately 3.7-volt per cell which is the average voltage during the discharge cycle.

What is the voltage of a lithium ion battery?

Additionally, the voltage of lithium-ion battery systems may differ slightly due to variations in the specific chemistry. For example, the nominal voltage of LiFePO4 batteries (a lithium-based popular alternative) is 3.2V per cell which is significantly lower than Litium-ion batteries’ average voltage (3.7V).

What is a low battery in a lithium ion battery?

Low Battery in Lithium-ion Batteries A low lithium-ion battery is a critical stage where the battery’s charge diminishes significantly, nearing depletion. Lithium-ion batteries exhibit distinct behavior as they approach low charge levels, unlike traditional battery types like alkaline or nickel-cadmium.

Why do lithium batteries change voltage?

These changes are closely related to the battery’s internal chemical reactions and physical characteristics. In the initial phase of charging, the lithium battery voltage is usually low, and as the internal chemical reactions of the battery gradually reach equilibrium, the voltage rises.

Learn More

- Tajikistan low rate lithium battery pack

- Cylindrical low temperature lithium battery

- Full-charge voltage of lithium battery pack

- How many strings are there in a 12v lithium battery pack

- How many strings are there of 21 volt lithium battery packs

- What is the use of high voltage lithium battery pack

- Lithium battery pack medium and high voltage box

- High voltage lithium battery pack protection solution

- The voltage of lithium battery pack fluctuates

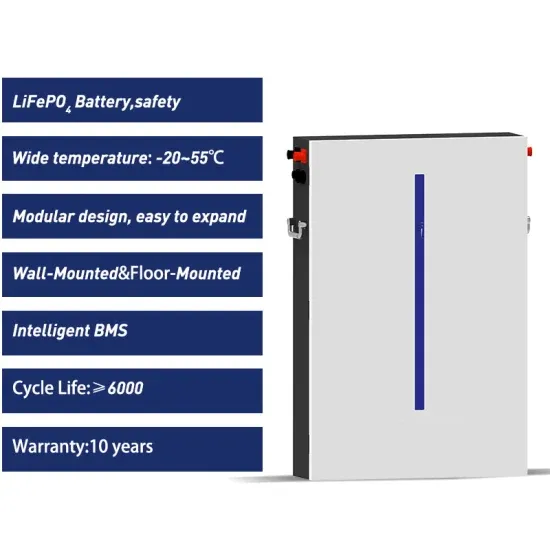

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.