Balancing Topology Research of Lithium-Ion Battery Pack

May 11, 2023 · The battery balancing system is based on energy, which is mainly to form energy conduction between high-power batteries and low-power batteries, so as to improve the

Lithium Battery Basics: A Crash Course

Apr 29, 2021 · What is the difference between a cell and a module? What is form factor? And why is it handy to know about C-rate? Regardless of whether you''re considering a career at a

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

5 days ago · Learn the differences between battery cells, modules, and packs. See how each layer works, why BMS and thermal systems matter, and where these components fit in EVs

Explore Battery Cells, Modules, And Packs: Key Differences

Understanding the distinctions between these battery components is essential for selecting the right battery configuration for specific applications. While battery cells serve as the

Cell geometry influences on the vibration performance of lithium

Feb 15, 2025 · Lithium-ion batteries are rechargeable energy storage systems in which lithium ions travel between negative and positive electrodes during charging and discharging [1]. In

The difference between steel-shell, aluminum

Nov 6, 2020 · The shell materials used in lithium batteries on the market can be roughly divided into three types: steel shell, aluminum shell and pouch cell

Lithium-ion cells, batteries, and other emerging storage

Jan 1, 2022 · Discussion then proceeds to lithium ion battery packs for automotive use. This includes brief description of high voltage battery pack systems. This is divided into the high

What is Battery Cell, Battery Module, and Battery

Jul 15, 2024 · It is important to understand the difference between a battery cell, battery module and battery pack if you work in industries such as electric

Integration issues of lithium-ion battery into electric vehicles

Feb 1, 2016 · In this work, the integration of Lithium-ion battery into an EV battery pack is investigated from different aspects, namely different battery chemistry, cell packaging, electric

What is the packaging technology of soft pack Li

Jun 11, 2022 · A Lithium-ion battery consists of positive electrode, negative electrode, electrolyte, diaphragm, etc. and shell packaging. According to the

Battery Management System of Electric Vehicle

Oct 28, 2022 · Battery Management System of Electric Vehicle Yuanjian Zhang and Zhuoran Hou Abstract Lithium-ion rechargeable cells have the highest energy density and are the standard

What Is A Lithium-Ion Battery Cell, Module, and Pack

Jan 30, 2024 · At the heart of every lithium-ion battery system is the individual cell. A battery cell is the basic building block that stores electrical energy through electrochemical reactions. In

Power Battery Basics: Cells, Modules & Packs Explained

Jan 4, 2024 · Today, we''ll explore the three most crucial elements: cells, battery modules, and battery packs. 1. Cells: The Building Blocks. Cells serve as the fundamental building blocks of

What is the difference between battery cells, battery

Feb 15, 2024 · In terms of shape, battery cell can be divided into square and cylindrical shapes. From the electro-hydraulic material, it can be divided into polymer lithium-ion batteries and

What is the difference between battery cells, battery

Feb 15, 2024 · The battery cell is the smallest unit that makes up the battery. The battery cell usually consists of a positive electrode, a negative electrode, a separator and an electrolyte

Prismatic Cells: structure, advantages and disadvantages

Apr 18, 2025 · The Lithium-ion batteries are divided into prismatic cells (such as commonly used cell phone battery cells), cylindrical lithium batteries (such as 18650, 18500, etc.), and pouch

Evaluation method for consistency of lithium-ion battery packs

Feb 1, 2024 · The promotion of electric vehicles (EVs) is important for energy conversion and traffic electrification, and the amelioration of fossil energy exhaustion and greenhouse gas

A complete analysis of battery cells, modules, battery packs

The battery cell is the basic unit of a battery, responsible for storing and releasing electrical energy. Lithium-ion battery cell packaging is primarily categorized into hard-shell and soft-shell

Battery Cells vs. Modules vs. Packs: How to Tell the Difference

5 days ago · Battery Cells vs. Modules vs. Packs: How to Tell the Difference Batteries drive almost everything—from pocket-size gadgets to electric vehicles (EVs) and grid storage. Yet

Lithium Battery Guidance Document

Jan 25, 2016 · Lithium Battery – The term "lithium battery" refers to a family of batteries with different chemistries, comprising many types of cathodes and electrolytes. For the purposes of

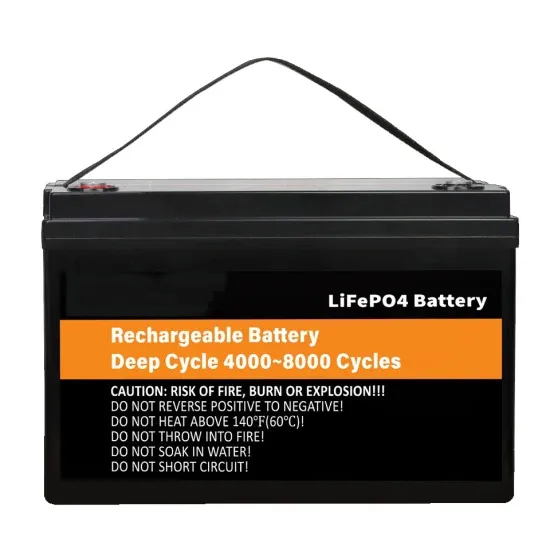

6 FAQs about [Lithium batteries are divided into cells and battery packs]

What is the structure of a lithium battery?

The general structure of lithium batteries is a cell, battery module and battery pack. Battery cell technology is the cornerstone of battery systems. The process of assembling lithium battery cells into groups is called PACK, which can be a single battery or a battery module connected in series and parallel.

What is a lithium battery module pack?

Lithium batteries are an essential part of modern technology, powering everything from smartphones to electric vehicles. While the terms “battery cell,” “battery module,” and “battery pack” are often used interchangeably, the battery cell module pack refers to different stages of the battery’s construction.

What are the different types of lithium ion battery cells?

Lithium-ion battery cells come in three main formats: cylindrical, prismatic, and pouch cells. Cylindrical battery cells were the first lithium-ion batteries to achieve mass production. They’re made by winding the cathode, anode, and separator in a specific order into a cylinder shape and then housing it in a metal casing.

How a battery pack works?

In the battery pack, to safely and effectively manage hundreds of single battery cells, the cells are not randomly placed in the power battery shell but orderly according to modules and packages. The smallest unit is the battery cell. A group of cells can form a module. Several modules can be combined into a package.

What is the process of assembling lithium battery cells into groups?

The process of assembling lithium battery cells into groups is called PACK, which can be a single battery or a battery module connected in series and parallel. The battery cell refers to the most basic component of the battery. Usually, an electrochemical device is enclosed in a metal casing.

What is the difference between battery module and battery pack?

The primary distinction between a battery module and a battery pack lies in their scale and functionality. A battery module is a smaller unit that contains a group of interconnected cells, often with its own BMS. It is a component within a larger battery pack, which consists of multiple modules arranged in a specific configuration.

Learn More

- How many lithium battery packs are needed for 60v

- 5 12v lithium battery packs

- The voltage of several lithium battery packs is consistent

- Lithium battery suitable for assembling battery packs

- 16 cells to make a lithium battery pack

- Where to assemble lithium battery packs in Macedonia

- Do lithium battery packs need additional containers

- Processing various types of lithium battery packs

- Power lithium battery packs can be mixed

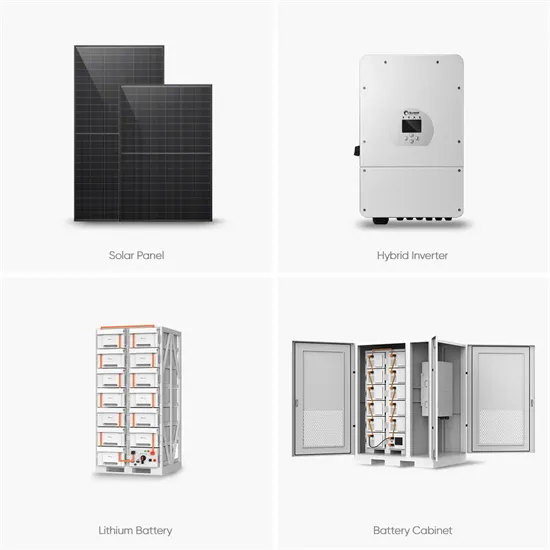

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.