How many 21700 cells are needed for a 60v battery pack

Which 18650 Battery Is Best For Your Ebike (A Helpful Chart) In total, thirteen 18650 battery cells are needed in a series connection for 48V. The nominal voltage of 18650 lithium-ion battery

Understanding the 60V Lithium Battery: Voltage, Capacity,

Feb 18, 2025 · Among the variety of lithium batteries available on the market, the 60V lithium battery stands out due to its powerful performance and versatility. In this article, we will explore

How many amperes is a 60v lithium battery pack

What Happens If You Build A Lithium Ion Battery Pack Without A BMS. Lithium-ion battery packs are composed of many lithium-ion cells in a complex series and parallel arrangement. Many

Typical Charging Time for a 60V Lithium Ion Battery

Jun 19, 2025 · The 60V lithium ion battery offers a balanced compromise between power and charging time, making it ideal for many modern electric vehicles. >>See also Top Questions

A Technical Guide to Electric Scooter Batteries

3 days ago · The battery is your electric scooter''s "fuel tank." It stores the energy that is consumed by the DC motor, lights, controller, and other accessories.

How Many 60 Volt Lithium Battery Packs Are Needed A

Whether you''re designing a solar storage system or powering industrial equipment, calculating how many 60 volt lithium battery packs you need depends on three key factors: energy

Battery Pack with Li-ion 60V for 2000 W BLDC Motor

Aug 22, 2018 · To be fair am very new to batteries management and DIY Battery packs, learning to make my own battery pack with 18650 li-ion batteries My Questions 1. i bought Kunray

How Many Cells in Series Are Needed for a 48V Battery?

Short answer: A 48V battery typically requires 13–16 lithium-ion cells in series, depending on cell chemistry. Lithium iron phosphate (LiFePO4) cells need 15–16 cells (3.2V each), while

Optimal Lithium Battery Charging: A Definitive

Mar 12, 2024 · Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

How many cells are needed for a 60v lithium battery pack

To successfully create a 60V lithium ion battery pack, you will need several key components: Lithium Ion Cells: These are the core energy storage units; typically, you will need cells rated

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

How many lithium battery packs are needed to charge 60v

Lithium Ion Battery Voltage Table This applies most lithium ion battery packs and chemistries which have with a nominal voltage of 3.6 V, full charge of 4.2 V and full discharge of 3.0 V.

Battery Pack Calculator | Good Calculators

Battery Pack Calculator Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and

How Can You Create Your Own 60V Lithium Ion Battery Pack?

Jul 19, 2024 · Creating your own 60V lithium ion battery pack can be an empowering project that enhances your understanding of energy storage systems while providing a reliable power

How many strings are 48V20AH lithium battery

Mar 3, 2021 · The whole set of batteries is 14 strings multiplied by 10 cells = 140 cells. Summary: Series and parallel have their own advantages for lithium iron

How many strings are there of 60v lithium battery pack

How many strings should a lithium battery have? Therefore,the lithium battery must also be about 58v,so it must be 14 stringsto 58.8v,14 times 4.2,and the iron-lithium full charge is about 3.4v,it

How many lithium battery packs are needed to charge 60v

Nominal voltage chart for 60V (16S) Li-Ion Ebike batteries showing the percentage. 16 Cells x 4.2 Volts/Cell = 67.2 Volts Fully Charged Voltage (V)... Assumptions: Your pack uses typical

How Many Lithium Batteries Are Needed for a 60V Golf Cart?

Aug 8, 2024 · Since most lithium batteries have a nominal voltage of 3.2V per cell (LiFePO4 chemistry), you need 20 cells in series (3.2V × 20 = 64V nominal) or commonly, lithium battery

How Many Strings of 60V Lithium Battery Packs Are Ideal

Summary: Determining the optimal number of 60V lithium battery strings depends on voltage requirements, energy capacity, and application scenarios. This guide explains key calculation

6 FAQs about [How many lithium battery packs are needed for 60v]

How do I calculate the capacity of a lithium-ion battery pack?

To calculate the capacity of a lithium-ion battery pack, follow these steps: Determine the Capacity of Individual Cells: Each 18650 cell has a specific capacity, usually between 2,500mAh (2.5Ah) and 3,500mAh (3.5Ah). Identify the Parallel Configuration: Count the number of cells connected in parallel.

How many cells do I need to create a battery pack?

So, you would need 42 cells in total to create a battery pack with 24V and 20Ah using cells with 3.7V and 3.5Ah. 1. Why do I need to connect cells in series for voltage? Connecting cells in series increases the overall voltage of the battery pack by adding the voltage of each individual cell.

What are the different types of lithium battery packs?

Lithium battery series and parallel: There are both parallel and series combinations in the middle of the battery pack, which increases the voltage and increases the capacity. Such as 4000mAh, 6000mAh, 8000mAh, 5Ah, 10Ah, 20Ah, 30Ah, 50Ah, 100Ah and so on. Take 48V 20Ah lithium battery pack as an example Lithium Battery PACK

How do you calculate the voltage of a battery pack?

The voltage of a battery pack is determined by the series configuration. Each 18650 cell typically has a nominal voltage of 3.7V. To calculate the total voltage of the battery pack, multiply the number of cells in series by the nominal voltage of one cell.

How do you calculate the number of cells in a battery pack?

To calculate the number of cells in a battery pack, both in series and parallel, use the following formulas: 1. Number of Cells in Series (to achieve the desired voltage): Number of Series Cells = Desired Voltage / Cell Voltage 2. Number of Cells in Parallel (to achieve the desired capacity):

What is a lithium-ion battery pack?

Lithium-ion batteries, particularly the 18650 battery pack design, have become the industry standard for many applications due to their high energy density and long lifespan. Understanding how to calculate a lithium-ion battery pack's capacity and runtime is essential for ensuring optimal performance and efficiency in devices and systems.

Learn More

- How fast is considered fast charging for lithium battery packs

- Equipment needed to process lithium battery packs

- How many amperes are there in 40 lithium battery packs of 36v

- How much does a lithium battery pack cost per kilowatt-hour

- How long can the lithium iron phosphate battery of the energy storage cabinet be used

- How to change the lithium battery station cabinet to photovoltaic power supply

- How much electricity can the Czech Brno lithium battery pack store

- How long does it take for the lithium iron phosphate battery station cabinet to charge the base station

- How to start charging the base station lithium battery

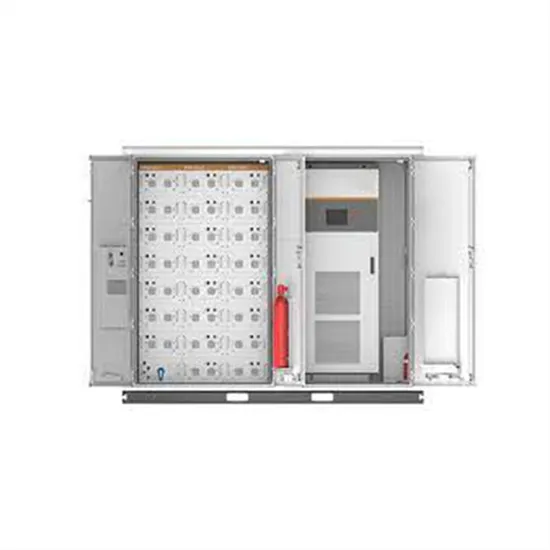

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

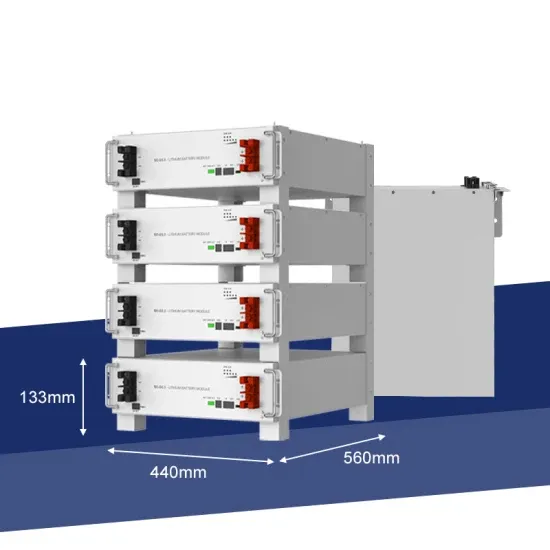

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.