DIY Lithium Ion: A Guide To Making Your Own Battery

Dec 31, 2023 · Choosing the Right Lithium Ion Cells When embarking on the journey of creating your own lithium ion battery, selecting the appropriate lithium ion cells is a critical decision that

How Many Cells in a Lithium Battery Pack? A Complete

Mar 14, 2025 · The arrangement and number of cells impact the battery pack''s overall capacity and performance. Users should consider these factors when selecting or building a battery

How to build your own lithium ion battery pack

Pack NCR18650B 3400mAH Li-ion Battery To build your own battery pack, you will need a few essential components such as battery cells, a battery mana. ement system, a battery

How to Build a Lithium Battery: Step-by-Step for Beginners

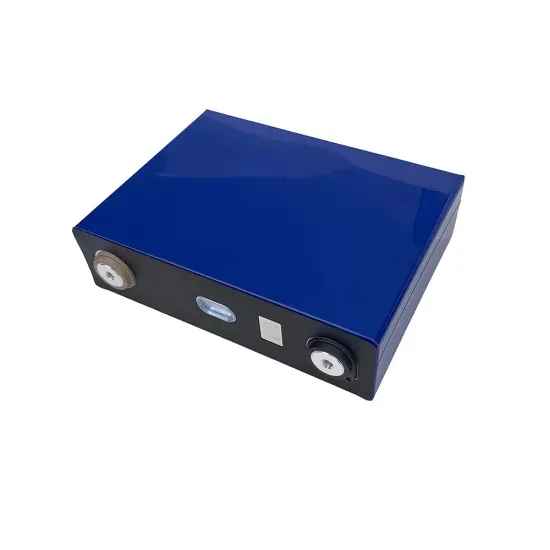

Feb 22, 2024 · How to build a lithium battery pack? 1. Prepare materials and tools. The following materials and tools are required to assemble the lithium battery pack. a. Lithium battery cell:

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Proper assembly is crucial for maximizing the safety, efficiency, lifespan, and performance of a lithium battery pack, making it essential for reliable and long-term usage.

Lithium Battery Assembly: Cell Stack Setup Tips

Apr 9, 2025 · A cell stack is the backbone of any lithium battery system. It''s the structured grouping of individual battery cells that deliver the desired power

How to Build a Lithium Ion Battery Pack? A Step by Step

Apr 9, 2025 · Below is a list of materials and tools that need to be prepared in how to build a lithium ion battery pack that is efficient and safe. Select the appropriate battery cells, such as

BU-305: Building a Lithium-ion Pack

Oct 25, 2021 · BU-305: Building a Lithium-ion Pack Building a Li-ion battery pack begins by satisfying voltage and runtime requirements, and then taking loading, environmental, size and

Building 12V Battery Packs with 18650 Cells: A Guide

Jun 8, 2024 · To build a 12V battery pack with 18650 cells, connect four cells in series (3.7V each) to achieve approximately 14.8V nominal. Use appropriate battery management systems (BMS)

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP). Modules: Groups of

How to Make a 24V Battery Pack

Apr 10, 2025 · Creating a 24V battery pack involves connecting two 12V batteries in series or assembling individual lithium cells to achieve the desired voltage and capacity. Have you ever

DIY Professional 18650 Battery Pack

In this Instructable, I will show you, how to make a 18650 battery pack for applications like Power Bank, Solar Generator, e-Bike, Power wall etc. The fundamental is very simple: Just to

3.2V LiFePO4 Cell Configurations To Build 12V,

Jul 7, 2023 · A 16-cell LiFeP04 51.2V pack offers superior performance compared to that of a 15-cell 48V pack with the same grade cells as the 16-cell pack.

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

6 FAQs about [16 cells to make a lithium battery pack]

Should you build a lithium-ion battery pack from 18650 cells?

As you can see, there is quite a bit to consider when building a lithium-ion battery pack from 18650 cells. It can be quite difficult for a busy person to take the time to learn all of these terms when they really just want a battery. Before you build, make sure you check out our comprehensive guide on safety when working with lithium-ion cells.

What are the basic components of a lithium-ion battery pack?

Before diving into the design process, it's crucial to understand the fundamental components of a lithium-ion battery pack: Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP).

How to build a battery using lithium ion cells?

To build a battery using lithium-ion cells that is close to 12V without going too much over is going to be a 3S configuration. This is because lithium-ion cells have a nominal voltage of 3.7V. So, 3 cells in series would give you a voltage of 11.1V. Remember, connecting cells in series adds their voltage but does not change their mAh.

How many lithium ion cells to make a 100Ah battery?

You would need 120 2500mAh lithium-ion cells to make a 100Ah battery. As you can see, there is quite a bit to consider when building a lithium-ion battery pack from 18650 cells. It can be quite difficult for a busy person to take the time to learn all of these terms when they really just want a battery.

How many lithium ion cells should a 24 volt battery pack have?

We have already determined that we need to run a 24-volt load. When building a 24-volt battery pack, it's best to use 7 cells in series. This is because lithium-ion cells have a depleted voltage of about 2.6 volts, a nominal voltage of 3.7 volts, and a fully charged voltage of 4.2 volts.

What are the components of a battery pack?

Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP). Modules: Groups of cells assembled together in a specific configuration (series, parallel, or a combination) to achieve the desired voltage and capacity.

Learn More

- What equipment is needed to make lithium battery pack

- 4V large capacity lithium battery pack accessories

- Lithium battery assembly pack equipment

- 36v lithium battery pack self-discharge

- 36v lithium battery pack to 12v

- 60kwh lithium iron phosphate battery pack price

- 12v80ah lithium battery pack

- Austria forklift lithium battery pack wholesale

- 18V 2A lithium battery pack

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.