XiCha Forklift Lithium Battery – XiCha Part Co., Ltd. –

Based in Shanghai, XiCha Part specializes in advanced lithium battery solutions and industrial vehicle components. With years of expertise in the forklift industry, we focus on high

What Are Industrial Lithium Forklift Batteries?

Jul 23, 2025 · Industrial lithium forklift batteries are advanced energy storage systems designed for material handling equipment, utilizing lithium-ion chemistry (e.g., LiFePO4) for higher

OEM portable forklift lithium battery pack Factory,Wholesale

Lifttop specializes in production portable forklift lithium battery pack with 21+ years of industry experience,wholesale high quality portable forklift lithium battery pack at lifttops . 50000+

How to Select the Best Wholesale Forklift Lithium Battery

Dec 17, 2024 · Wholesale forklift lithium batteries are essential for enhancing the efficiency and performance of electric forklifts. These batteries offer high energy density, long lifespan, and

Why Are High-Capacity Lithium Batteries the Best Choice for Forklifts

High-capacity forklift power batteries are essential for efficient and prolonged industrial operations. Selecting the right manufacturer and supplier ensures optimal performance, longevity, and

China Forklift Lithium Battery Manufacturers Suppliers

A high-tech enterprise: Specializing in the research, production, sales and market application development of lithium-ion power batteries, battery packs, battery management systems,

Why Switch To Forklift Lithium Battery For Industrial

Apr 28, 2025 · Forklift lithium batteries offer 2-3x faster charging, 50%+ lifespan gains, and zero maintenance versus lead-acid. With 30% energy savings and opportunity charging

forklift battery packs, forklift battery packs Suppliers and

59693 forklift battery packs products are offered for sale by suppliers on Alibaba , of which lithium ion batteries accounts for 86%, forklifts accounts for 2%, and other batteries accounts

lithium batteries Austria | B2B companies and suppliers

We can offer not only EXIDE NP accumulators but also Tadiran lithiumbatteries (formerly Sonnenschein lithium), NiCd batteries, starter batteries, and power supplies of every

Wholesale 48V 450AH Forklift Battery factory and suppliers

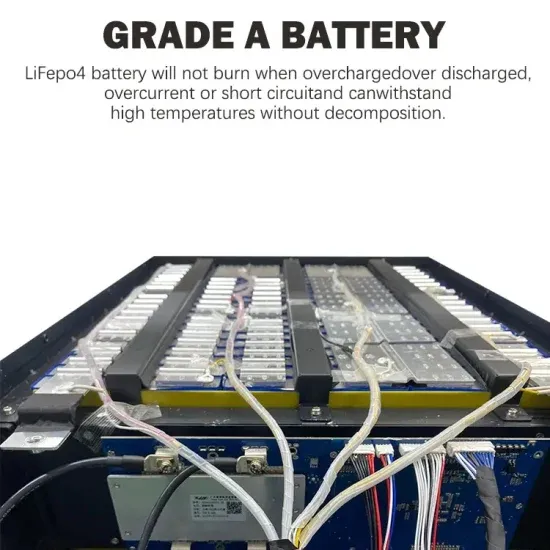

Feb 8, 2025 · Our Battery Cells High-Capacity 48V 450Ah Forklift Battery:Made with high-quality battery cellsExcellent energy density and power outputFast charging capabilitiesCost-effective

Lithium-Ion Forklift Battery: A Full Resource Guide

Sep 10, 2024 · Lithium Ion Forklift Batteries have revolutionized material handling. This guide covers their benefits, charging, maintenance, and key features.

Fork Lift Batteries (Fork lift storage battery, Forklift battery)

Feb 18, 2025 · Fork Lift Batteries - You find here 41 suppliers from China Australia Germany Austria Italy Switzerland Poland Sweden and Iran. Please obtain more information on spare

How Much Does a Forklift Battery Weigh? A Comprehensive

Feb 27, 2025 · Forklift batteries are the powerhouse behind material handling operations, with weights ranging from 1,000 to 4,000 pounds depending on critical factors like voltage,

Top 5 Forklift Lithium-Ion Battery Suppliers in Europe 2025

May 10, 2025 · Lithium-ion forklift batteries offer faster charging, longer operational life, and virtually maintenance-free use compared to lead-acid batteries. They enable opportunity

What Are Forklift Battery Sizes and Configurations?

Sep 23, 2024 · Understanding forklift battery sizes and configurations is essential for optimizing performance in material handling operations. This guide will help you navigate through various

6 FAQs about [Austria forklift lithium battery pack wholesale]

What is a lithium forklift battery?

These lithium forklift batteries designed with high quality LiFePO4 lithium batteries, built in last 4000 times cycle life. Available in various 24V, 36V, 48V, and 80V configurations suitable for Class I, II, and III material handling equipment. Specialized In Providing Custom Lithium Battery Solutions ! Contact: [email protected] HOME

How long does a lithium forklift battery last?

Overall savings are quite significant for the lithium battery. How Long Does A Forklift Battery Last? Lithium forklift batteries usually last for 4,000 times cycles, while lead acid batteries for 1,000 to 1,500 times cycles. Also the lithium batteries are lower maintenance than lead acid batteries.

Are lithium forklift batteries safe?

However, the lithium forklift batteries are seal. So there is no potential for acid spills, corrosion, sulfation, or any sort of contamination in the workplace. IIn fact, so far, there have been no cases of safety hazards in forklift lithium batteries.

What is a 36V forklift battery?

The 36V forklift batteries are designed for mid-sized electric equipment, such as: Narrow aisle forklifts 3 wheel sit-downs There is a typical 36V 800Ah forklift battery spec that we designed. 36V 800Ah forklift battery 48V Forklift Battery The 48V forklift batteries are designed for large electric equipment, such as: Counterbalanced forklifts

What is the difference between lead acid and lithium forklift batteries?

Lithium forklift batteries usually last for 4,000 times cycles, while lead acid batteries for 1,000 to 1,500 times cycles. Also the lithium batteries are lower maintenance than lead acid batteries. Lead acid batteries need to be kept topped up with water to protect the lead plates inside them.

What is a wet battery in a forklift?

Lead-acid Batteries The most common forklift batteries, wet batteries are those that contain a charging plate suspended in a mixture of sulfuric acid and water. The battery works by suspending an electrolyte between 2 oppositely charged plates in a mixture of water and acid. Evaporation occurs during operation and charging.

Learn More

- Saudi Arabia Electric Forklift Lithium Battery Pack

- Liechtenstein electric forklift lithium battery pack

- Majuro lithium battery pack wholesale

- Which is the best lithium battery pack for forklift in Armenia

- Vienna lithium battery pack

- Tbilisi lithium battery pack equipment

- 36v lithium battery pack balancing

- Montevideo 12v lithium battery pack

- 4 5v lithium battery pack

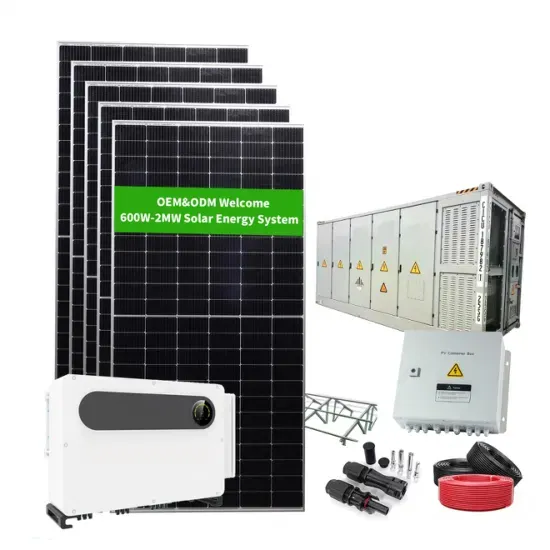

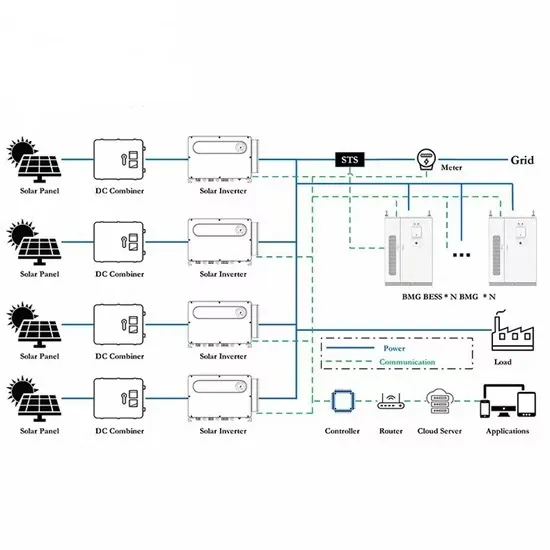

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.