What To Look For In An Electric Forklift Battery?

Jul 23, 2025 · Electric forklift batteries require evaluating voltage (24V–80V), capacity (100–1200Ah), and chemistry (LiFePO4 vs. lead-acid). Prioritize cycle life (2,000+ cycles for

Lithium Forklift Batteries: The Complete Guide [Pros, Cons,

Forklift lithium battery packs are advanced energy systems using lithium-ion cells (primarily LiFePO4) to power electric forklifts. With voltages of 24V to 80V and capacities from 100Ah to

How to Select the Right Lithium-Ion Forklift

Sep 10, 2024 · When selecting a lithium-ion forklift battery, it''s essential to choose the right voltage and capacity based on your forklift''s specifications. Voltage

Things to Consider When Using Lithium Batteries in

1 day ago · Why Lithium Batteries Are Changing Counterbalanced Forklifts The first thing to understand is why lithium batteries are so appealing in counterbalanced forklifts. Compared to

What Is the Typical Lifespan of a Forklift Battery Pack?

Jul 21, 2025 · A: A typical lithium-ion forklift battery pack can last approximately 5,000 charge cycles, offering an extended service life compared to lead-acid options. Q: What is the

Top 10 forklift battery suppliers in China in 2021

Nov 30, 2021 · The war of Lithium forklift battery The acceptance degree of lithium forklift battery is improving The production of lithium forklift battery still

BSLBATT Industrial Lithium Batteries

Jul 26, 1997 · Forklift Battery Specifications: Capacity, Size and Weight BSLBATT® has several standard battery types by voltage (24V, 36V, 48V, 72V, 80V, 96V, 121.6V, 144V) and different

How to choose forklift lithium batteries?

Aug 15, 2025 · How to choose a forklift lithium battery pack for electric forklifts? The first thing to do in finding high-quality products is to understand the manufacturer''s brand, scale, technical

Which Battery Type Is Best for Your Forklift:

4 days ago · Within the world of material handling, electric-powered vehicles typically utilise two types of batteries: lithium-ion (Li-ion) and lead-acid. Each

Lithium Forklift Batteries: The Complete Guide

Feb 7, 2025 · That includes: Key differences between lithium-ion and lead-acid The major features, advantages, and benefits of lithium-ion What you need to

What Are the Best Lithium-Ion Batteries for Forklifts in 2025?

Mar 7, 2025 · The best lithium-ion batteries for forklifts in 2025 combine long cycle life, rapid charging, maintenance-free operation, and compatibility with major forklift brands. Leading

Forklift Battery: Best Picks and Safety Practices | TRADESAFE

May 20, 2024 · Discover the forklift battery best picks in this buying guide. Find all you need to know about battery charging safety practices and maintenance tips.

How to Choose the Right Forklift Battery Pack for Your

Nov 15, 2024 · Lithium-ion forklift batteries are revolutionizing material handling operations by offering longer lifespans, faster charging times, and greater energy efficiency compared to

How to Choose the Right Forklift Battery Pack for Your Needs

Nov 13, 2024 · Choosing the right forklift battery pack is crucial for efficient operations in material handling. This guide will help you understand the manufacturing process, key features, and

Best 10 Lithium-Ion Forklift Batteries You Should Consider

Oct 25, 2024 · Ufine 48 V 100Ah LiFePO4 Battery. Specifications. Max. Charge/Discharge Current: 100A. Pros. Fast charging reduces downtime significantly. Environmentally friendly

XiCha Forklift Lithium Battery – XiCha Part Co., Ltd. –

Based in Shanghai, XiCha Part specializes in advanced lithium battery solutions and industrial vehicle components. With years of expertise in the forklift industry, we focus on high

Lithium battery fire!

Jun 20, 2025 · Lithium batteries on forklift trucks For fires associated with forklift lithium batteries, the recommended fire extinguisher type is typically a Class D fire extinguisher, specifically

The Lithium Battery Forklifts and How They Can Improve

Sep 28, 2021 · This guide is a thorough analysis of the advantages of lithium battery forklifts and how they differ from lead-acid models. Read more about it here.

Lithium-Ion Forklift Battery Manufacturers Companies

The Forklift Battery Manufacturer We especially offer a wide range of lithium iron Phosphate (LiFePO4) batteries for electric forklift truck, each specifically engineered to deliver a high

6 FAQs about [Which is the best lithium battery pack for forklift in Armenia]

What are the best lithium-ion forklift batteries?

The best lithium-ion forklift batteries prioritize energy density, safety, and ROI. Brands like Redway Power and Toyota lead with innovations in BMS and thermal management. By optimizing charging habits and leveraging warranties up to 10 years, businesses achieve 30% lower costs and 20% higher productivity.

What are the advantages of lithium ion forklift batteries?

Lithium-ion forklift batteries offer several advantages: Take less than two hours to recharge. Recycled up to three times longer. Safer than conventional batteries. 1. Ufine 48 V 100Ah LiFePO4 Battery Specifications Max. Charge/Discharge Current: 100A Pros Fast charging reduces downtime significantly.

How many lithium ion batteries do you need for a forklift?

So, you may need 2 to 3 lead-acid batteries per forklift for a multi-shift operation or you’ll experience downtimes. A lithium-ion forklift battery gets fully charged in 2 hours or less and does not require a cooling-off period. Plus, you can charge your Li-ion battery in 15-30-minute spurts, called opportunity charging.

How long do lithium ion forklift batteries last?

Lithium-ion forklift batteries last longer than lead-acid batteries. Whereas a lead-acid battery might last 1,500 cycles under good maintenance, a lithium forklift battery lifespan can last between 2,000 and 3,000 cycles. Lithium-ion forklift batteries are more expensive than lead-acid.

Are lithium forklift batteries better than lead-acid batteries?

Energy bills: Lithium forklift batteries are 30% more energy-efficient and charge 8X faster than lead-acid batteries. Downtime: Lithium batteries can be opportunity-charged during operator breaks and don’t need to be swapped, saving downtime and longer run times.

What is a lithium ion forklift battery?

Lithium-ion forklift batteries are composed of the following: 2 current collectors (positive and negative). To generate electric energy, different chemistries occur in lithium-ion batteries, with the most popular one for forklifts being lithium iron phosphate. The anode and cathode store the lithium.

Learn More

- Which is the best lithium battery pack for flashlight

- Which company has the best quality of monitoring lithium battery pack

- Tuvalu forklift lithium battery pack

- Which lithium battery is the best in Freetown

- Electric forklift lithium battery pack

- Vilnius electric forklift lithium battery pack

- Which lithium battery pack

- Liechtenstein electric forklift lithium battery pack

- Which brand of power lithium battery pack is good

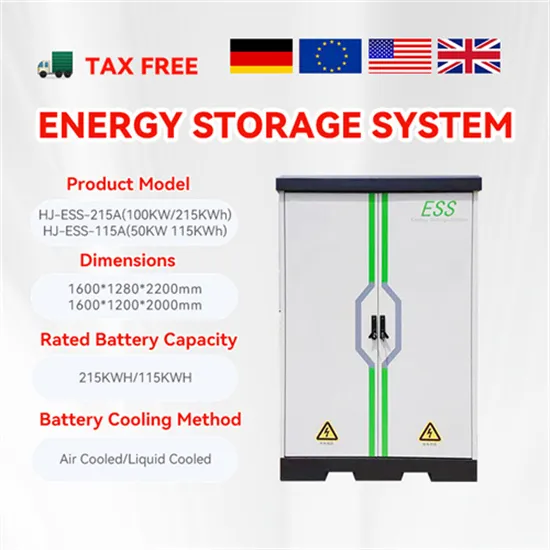

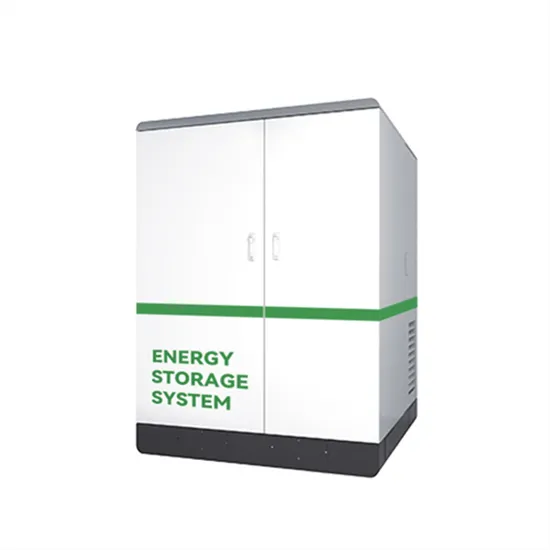

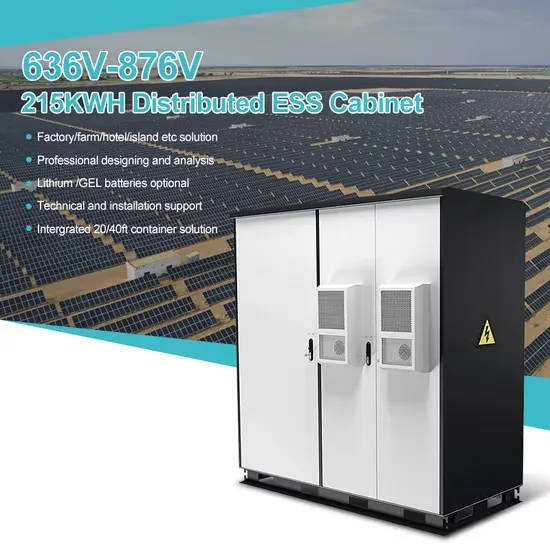

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

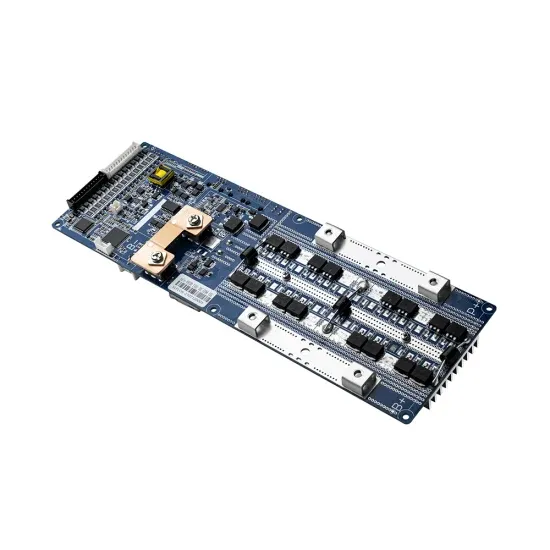

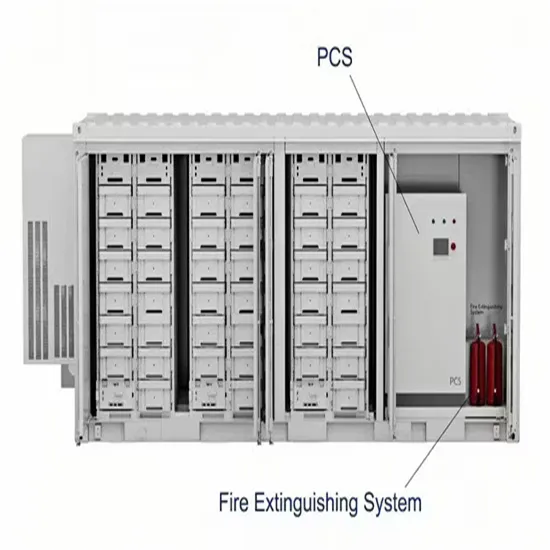

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.