How to Choose the Right Forklift Battery Pack for Your Needs

Nov 13, 2024 · Choosing the right forklift battery pack is crucial for efficient operations in material handling. This guide will help you understand the manufacturing process, key features, and

Fusion Battery The Future of Forklift Power

The Future of Forklift Power CLARK proudly offers a full line of electric forklifts that can be equipped with an aftermarket CLARK FUSION lithium-ion battery. With an operator-friendly

Lithium-Ion Forklift Battery: A Full Resource Guide

Sep 10, 2024 · Lithium-ion batteries have revolutionized the material handling industry, particularly in the operation of forklifts. This comprehensive guide will

Lithium-ion battery prices in Vilnius

The average price for a lithium-ion forklift battery is roughly $17-20k (about 2-2.5x more than a similar lead-acid battery). For that higher upfront price, an operation will save money on:

Lithium batteries for electric forklift trucks

The transition to lithium batteries for forklift trucks represents a decisive step forward. Not only do they replace lead-acid batteries, but they also enable you to switch from thermal forklifts to

The Ultimate Guide to Forklift Batteries

Electric forklifts are essential in modern logistics and warehousing operations, prized for their efficiency and lower environmental impact. Maximizing the useful life of your electric forklift

Top 10 forklift battery suppliers in China in 2021

Nov 30, 2021 · The war of Lithium forklift battery The acceptance degree of lithium forklift battery is improving Whether active or passive, lithium forklift

Lithium-Ion Batteries for Electric Forklifts: Benefits and

Reduced Environmental Impact: Electric forklifts powered by lithium-ion batteries produce zero emissions, making them a more environmentally friendly option compared to internal

Forklift Lithium Battery | EVlithium

Aug 14, 2025 · Forklift lithium batteries are a dependable and cost-effective power source that is designed to offer unbeatable performance in terms of efficiency, durability, and efficacy in all

XiCha Forklift Lithium Battery – XiCha Part Co., Ltd. –

Based in Shanghai, XiCha Part specializes in advanced lithium battery solutions and industrial vehicle components. With years of expertise in the forklift industry, we focus on high

Industrial Lithium Battery Manufacturers/Suppliers | BSLBATT Battery

Jul 26, 1997 · Industrial Lithium Battery Manufacturer Founded in 2012, BSLBATT is an innovative high-tech company that designs and manufactures intelligent lithium-ion batteries (up to 50%

Lithium-Ion Battery Packs for Electric Forklifts: Benefits, Specs

Aug 16, 2025 · Upgrade your forklifts with lithium-ion battery packs. Learn key benefits, specs, maintenance tips & why Shizen Energy India is the trusted choice

Lithium Forklift Batteries

Forklift Lithium Batteries More than 30,000 drivers choose BSLBATT lithium batteries. We provide more than 950 models of Lithium-ion batteries for electric industrial trucks. With 3000 cycle life,

Electric Forklift Lithium Battery Pack

Mar 27, 2025 · Name: Cold Chain Logistics Center Electric Forklift Lithium Battery Pack Project Product: Customer Customization Features: Extreme Temperature Operations: Operating in

Lithium-Ion Battery Packs for Electric Forklifts:

Aug 16, 2025 · Upgrading to lithium-ion battery packs for electric forklifts is a strategic investment decision that can help you realize benefits of forklift

BSLBATT Industrial Lithium Batteries

Jul 26, 1997 · Forklift Battery Specifications: Capacity, Size and Weight BSLBATT® has several standard battery types by voltage (24V, 36V, 48V, 72V, 80V, 96V, 121.6V, 144V) and different

Lithium and Lead Acid Batteries For Electric Forklifts | Total

Aug 19, 2025 · Switching from propane to electric forklifts powered by lithium-ion, TPPL, or lead-acid batteries is a game-changer. Our Electric Forklift Conversion Program has helped

What Are Lithium Forklift Batteries?

May 26, 2025 · Lithium forklift batteries are advanced power units using lithium-ion cells (e.g., LiFePO4) to energize electric forklifts in warehouses and logistics. They outperform lead-acid

5 FAQs about [Vilnius electric forklift lithium battery pack]

What is a lithium ion forklift battery?

Lithium-ion batteries are rechargeable batteries that use lithium ions as a key component of their electrochemistry. Lithium-ion batteries offer numerous advantages that make them increasingly popular in various applications, especially forklifts, unlike traditional lead-acid batteries. How Do Lithium-Ion Forklift Batteries Work?

Are lithium ion forklift batteries safe?

Lithium-ion batteries are considered safe for use in forklifts, as they do not emit toxic fumes and have built-in safety features to prevent accidents. How long do lithium-ion forklift batteries last? Lithium-ion batteries can last 2 to 4 times longer than lead-acid batteries, depending on usage and maintenance.

Do lithium-ion batteries need maintenance?

Although lithium-ion batteries require less maintenance than traditional batteries, some primary care is still necessary: Regular Monitoring: Regularly check the battery’s charge level to ensure optimal performance.

Do lithium ion batteries require a cooling-off period?

Dedicated Chargers: Lithium-ion batteries require specific chargers that match their voltage and current specifications. These chargers are often compact and user-friendly. No Cooling Period: Unlike lead-acid batteries, lithium-ion batteries do not require a cooling-off period after charging, allowing continuous operation. Part 4.

How long does it take to charge a forklift?

Forklifts can be charged in 15 to 30 minutes, making running multiple shifts without battery swaps possible. Dedicated Chargers: Lithium-ion batteries require specific chargers that match their voltage and current specifications. These chargers are often compact and user-friendly.

Learn More

- Electric forklift lithium battery pack

- Liechtenstein electric forklift lithium battery pack

- Saudi Arabia Electric Forklift Lithium Battery Pack

- Electric impact rammer lithium battery pack

- Electric lithium battery pack

- Which is the best lithium battery pack for forklift in Armenia

- Lithium battery pack electric wheel

- Rabat electric storage vehicle lithium battery pack

- Liberia electric storage vehicle lithium battery pack

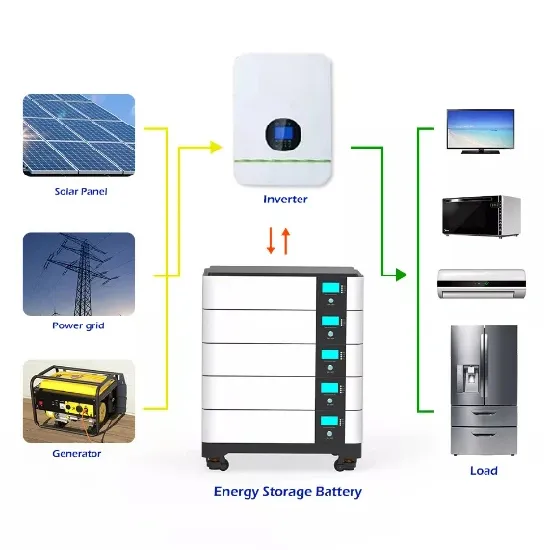

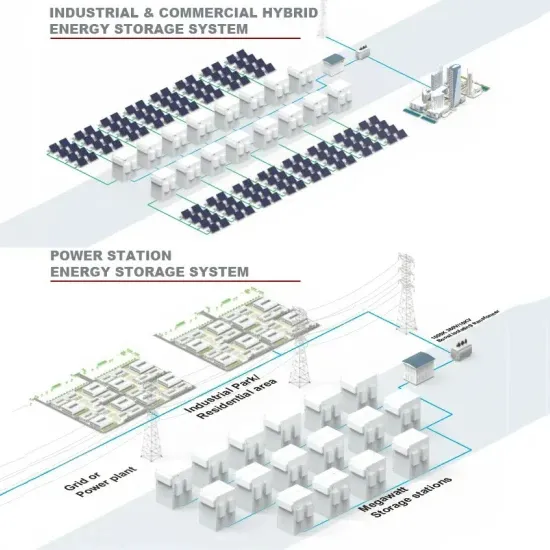

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.