How to Choose the Right Forklift Battery Pack for Your Needs

Nov 13, 2024 · Choosing the right forklift battery pack is crucial for efficient operations in material handling. This guide will help you understand the manufacturing process, key features, and

Lithium-Ion Forklift Battery Manufacturers Companies

The Forklift Battery Manufacturer We especially offer a wide range of lithium iron Phosphate (LiFePO4) batteries for electric forklift truck, each specifically engineered to deliver a high

ROYPOW® Official

4 days ago · Dedicated to the lithium-ion battery systems as one-stop solutions to achieve enegy innovation and build world-renowned renewable energy brand. At present, ROYPOW products

Lithium Forklift battery

Jul 26, 1997 · Industrial Lithium Battery Manufacturer Founded in 2012, BSLBATT is an innovative high-tech company that designs and manufactures intelligent lithium-ion batteries (up to 50%

Lithium Forklift Batteries: The Complete Guide

Feb 7, 2025 · That includes: Key differences between lithium-ion and lead-acid The major features, advantages, and benefits of lithium-ion What you need to

Tuvalu Forklift Lithium Battery Pack The Future of Efficient

With 92% of Tuvalu''s energy still imported through diesel generators, warehouses are turning to lithium forklift batteries to reduce operational costs. Unlike traditional lead-acid batteries

Lithium Forklift Batteries: The Complete Guide [Pros, Cons,

Sep 10, 2024 · Lithium-ion batteries have revolutionized the material handling industry, particularly in the operation of forklifts. This comprehensive guide will

Lithium Ion Forklift Batteries & LFP Batteries for

4 days ago · ROYPOW specializes in developing lithium forklift batteries, boosting truck productivity with more shifts and less charging time. Our cells range from

BSLBATT Industrial Lithium Batteries

Jul 26, 1997 · Forklift Battery Specifications: Capacity, Size and Weight BSLBATT® has several standard battery types by voltage (24V, 36V, 48V, 72V, 80V, 96V, 121.6V, 144V) and different

Lithium-Ion Battery Packs for Electric Forklifts: Benefits, Specs

Aug 16, 2025 · Upgrading to lithium-ion battery packs for electric forklifts is a strategic investment decision that can help you realize benefits of forklift lithium-ion over traditional lead acid in

How to Choose the Right Forklift Battery Pack for Your

Nov 15, 2024 · Lithium-ion forklift batteries are revolutionizing material handling operations by offering longer lifespans, faster charging times, and greater energy efficiency compared to

Industrial Lithium Battery Manufacturers/Suppliers | BSLBATT Battery

Jul 26, 1997 · Industrial Lithium Battery Manufacturer Founded in 2012, BSLBATT is an innovative high-tech company that designs and manufactures intelligent lithium-ion batteries (up to 50%

What Are Lithium Forklift Batteries?

May 26, 2025 · What defines lithium forklift battery technology? Lithium forklift batteries leverage LiFePO4 or NMC cells for high energy density (150–200 Wh/kg) and 2000–5000 cycle

6 FAQs about [Tuvalu forklift lithium battery pack]

Are lithium ion forklift batteries easy to charge?

Reduced Maintenance: Unlike lead-acid batteries, lithium-ion batteries require minimal maintenance. There is no need for watering or equalization, making them easier to manage. Part 3. Charging lithium-ion forklift batteries Charging lithium-ion batteries is straightforward but requires specialized chargers designed for their unique chemistry.

What are the different types of lithium forklift batteries?

They depend on the type of cathode material used in them. The common lithium forklift battery options include: Lithium iron phosphate (LFP) is the most popular lithium forklift battery type in the modern material handling industry. It offers higher safety, and current and has a lower environmental impact than other types of lithium-ion batteries.

How many lithium ion batteries do you need for a forklift?

So, you may need 2 to 3 lead-acid batteries per forklift for a multi-shift operation or you’ll experience downtimes. A lithium-ion forklift battery gets fully charged in 2 hours or less and does not require a cooling-off period. Plus, you can charge your Li-ion battery in 15-30-minute spurts, called opportunity charging.

How long do lithium ion forklift batteries last?

Lithium-ion forklift batteries last longer than lead-acid batteries. Whereas a lead-acid battery might last 1,500 cycles under good maintenance, a lithium forklift battery lifespan can last between 2,000 and 3,000 cycles. Lithium-ion forklift batteries are more expensive than lead-acid.

Where can I buy lithium forklift batteries?

You can send an enquiry through the BSLBATT website or purchase lithium forklift batteries through our global network of distributors.BSLBATT has 118 distributors and after-sales service centres in the USA, Europe, South Africa, Mexico, Brazil, Japan, and Australia, providing 24/7 technical support to ensure seamless operation.

Which industries benefit most from lithium-ion industrial forklift batteries?

Multi-shift applications such as food processing, manufacturing, 3PL, and other 24/7 material handling operations benefit most from lithium-ion industrial forklift batteries. Operations where forklifts work in cold environments also quickly benefit from lithium-ion batteries.

Learn More

- Liechtenstein electric forklift lithium battery pack

- Which is the best lithium battery pack for forklift in Armenia

- Saudi Arabia Electric Forklift Lithium Battery Pack

- Austria forklift lithium battery pack wholesale

- Intelligent home lithium battery pack in Antwerp Belgium

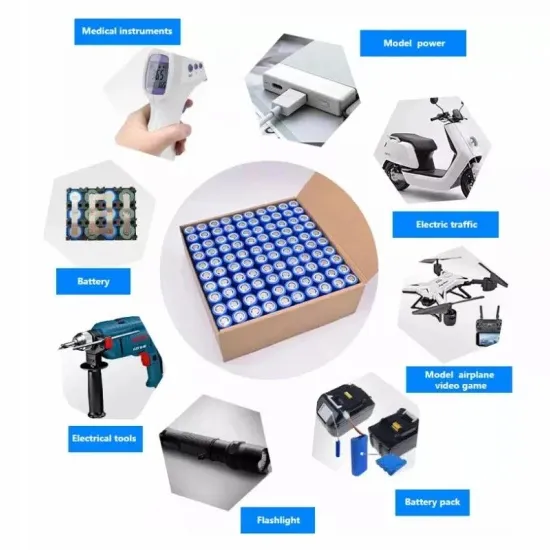

- Specialized in 60v lithium battery pack for electric tools

- Liberia electric storage vehicle lithium battery pack

- Electric flat car lithium battery pack

- Lithium battery pack 8s

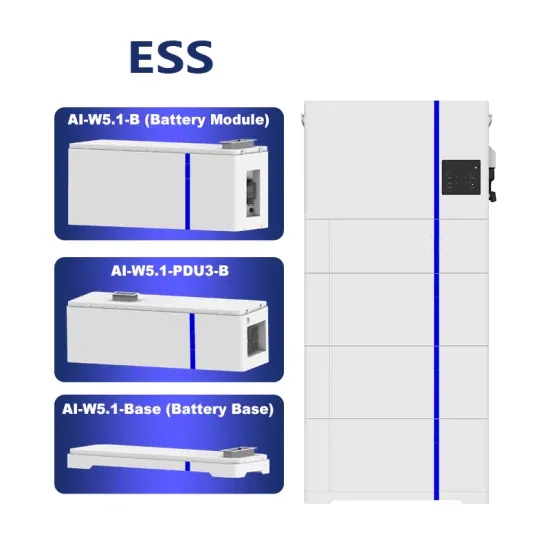

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.