Electric Flat Car 48v 320ah Longest Lasting Solar Batteryries Ev Pack

Our battery packs are tested under the condition of 0.5C charging ratio of 100% depth of discharge (DOD). If we use a 0.25C charging ratio, our battery packs can reach more than

Flat Circle Battery vs. Traditional Lithium-ion Cells

Apr 5, 2025 · Flat circle batteries vs lithium-ion cells A technical comparison of design performance safety cost and applications to help you choose the right

Will my battery go flat if I leave my EV parked

Aug 8, 2021 · The rate at which an EV''s high-voltage lithium-ion traction battery pack, the one that powers the wheels, loses charge if left idle is usually very

Enabling New EV Battery Chemistries Through Battery Pack

Jan 7, 2025 · This article discusses the changes in battery pack design that impact which cell chemistries can be used in a commercially viable way. An overview is given for future adoption

electric flat car battery for Electronic Appliances

Get the bestselling electric flat car battery on Alibaba at unrivaled discounts and enjoy high-performance output. The electric flat car battery are durable to ensure value for your money.

High-Capacity Electric Flat Car with Lithium Battery Power

Jul 31, 2025 · High-Performance electric flat car The electric flat car is a versatile and efficient material handling solution designed for various industrial applications. Powered by electric

High thermal performance lithium-ion battery pack including

Jun 1, 2014 · In this study, a novel Li-ion battery pack design including hybrid active–passive thermal management system is presented. The battery pack is suitable for using in

The Handbook of Lithium-Ion Battery Pack Design:

May 16, 2024 · Today he serves as chief customer officer for American Battery Solutions, a lithium-ion battery pack manufacturer based in Michigan and Ohio. He is founder and

Battery Cell, Module, Pack, what`s the Difference?

Nov 20, 2024 · As electric cars become increasingly common in our daily lives, terms like "battery cell," "module," and "pack" pop up frequently. But what

Introduction to Electric Vehicle Battery Modules and Packs

4 days ago · EV battery packs are full-sized batteries capable of powering an entire electric vehicle. The heaviest part of an EV at an average weight of 1,000 lbs (450 kg), it has an

Exploring the Power of Flat Lithium Ion Batteries

Jul 25, 2024 · Flat lithium-ion batteries power devices from phones to vehicles. This article explores their design, benefits, types, applications, charging, and

Revolutionizing the Road: The Power of Electric

Dec 16, 2023 · If you''re in the market for an eco-friendly and sustainable vehicle, then electric cars are definitely worth considering. Not only do they produce

Designing the Heart of Electric Vehicles: The

Nov 4, 2023 · At the heart of these cutting-edge vehicles lies the lithium battery pack, a sophisticated assembly that powers the EVs and stores electrical energy.

EV Battery Pack Designs: From Modules to Body-Integrated

Jun 4, 2025 · Individual cells (left) are grouped into modules, and modules into the full pack. Next-gen packs cut out the modules. Electric vehicles carry a whole power plant under their floors –

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Designing a Lithium-Ion Battery Pack: A Comprehensive Guide In recent years, the demand for efficient and powerful energy storage solutions has surged, primarily driven by

Top 7 EV Battery Pack Suppliers in China

Apr 23, 2025 · Explore the top 10 electric vehicle battery pack suppliers in China, providing innovative and efficient solutions for the EV market. 1. Leap Motor —

Optimization of liquid cooling and heat dissipation system of lithium

Aug 1, 2021 · A stable and efficient cooling and heat dissipation system of lithium battery pack is very important for electric vehicles. The temperature uniformity design of the battery packs has

6 FAQs about [Electric flat car lithium battery pack]

What are EV traction battery packs?

EV traction battery packs are the lifeblood of electric vehicles, enabling their environmental and economic benefits. Their design and functionality determine the range, efficiency, and overall user experience of EVs.

What are EV battery packs?

EV battery packs are the final product, assembled as well in series or parallel within a hard housing. They may also contain other components, including monitoring software and thermal management. As you can see, EV battery design has the elements arranged in a specific hierarchy.

What is a hybrid battery pack?

Commonly found in HEVs, small hybrid battery packs function in complement to the larger internal combustion engine (ICE). They are ideal for short distance trips (i.e., 30-50 miles), with longer distances reserved to the ICE. EV battery packs are full-sized batteries capable of powering an entire electric vehicle.

What is a traction battery pack?

They provide the power required to propel the vehicle by supplying electricity to the electric motor. Unlike conventional lead-acid batteries used in starter motors, traction battery packs are high-capacity lithium-ion (Li-ion) batteries engineered for sustained energy output, high energy density, and longevity.

How do EV batteries work?

Cells are grouped into modules, which are then assembled into a battery pack. This modular design allows scalability for different EV models. The BMS is the brain of the battery pack, responsible for monitoring cell voltages, managing temperature, and ensuring safe charging and discharging cycles.

What are EV battery modules?

EV battery modules each consist of a number of EV battery cells connected in series or parallel, forming units that produce the required voltage and energy capacity. EV battery packs are the final product, assembled as well in series or parallel within a hard housing.

Learn More

- Copenhagen electric storage vehicle lithium battery pack

- Liechtenstein electric forklift lithium battery pack

- Masai electric storage vehicle lithium battery pack

- Rabat electric storage vehicle lithium battery pack

- Specialized in 60v lithium battery pack for electric tools

- Battery pack uses lithium battery

- ASEAN lithium battery pack manufacturers

- New Zealand 40A lithium battery pack

- Power battery for lithium battery pack

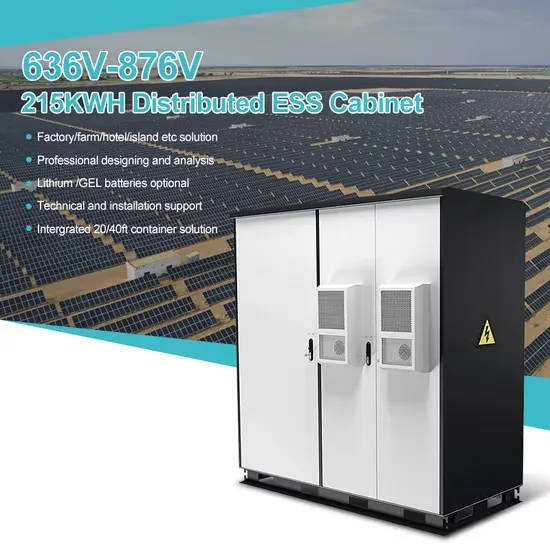

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

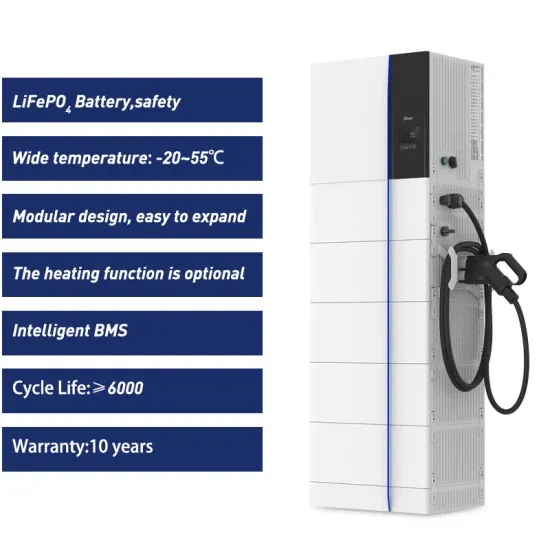

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.