China''s Solar Industry Absolutely Crushing It On Solar

Apr 14, 2025 · The Chinese manufacturer LONGi aims to shake up the global solar industry with a new 24.8% efficiency rating for its Hi-MO 9 solar module.

Research on hot spot risk of high wattage solar modules

Dec 1, 2021 · This research proves the effectiveness of using finite element analysis (FEA) to study the hotspot risk, and points out a new direction for how to control the hotspot risk of high

How many watts is a crystalline silicon solar panel? | NenPower

May 21, 2024 · How many watts is a crystalline silicon solar panel? A crystalline silicon solar panel typically produces between 250 and 400 watts, with the exact output contingent upon

Microsoft PowerPoint

Feb 24, 2011 · Crystalline silicon PV cells are used in the largest quantity of all types of panels on the market, representing about 90% of the world total PV cell production in 2008. The highest

Flexible silicon solar cells with high power-to-weight ratios

Jan 31, 2024 · It is found that the 57-μm flexible and thin solar cell shows the highest power-to-weight ratio (1.9 W g −1) and open-circuit voltage (761 mV) compared to the thick ones.

How many watts is the efficiency of silicon solar

May 16, 2024 · The average efficiency of silicon solar cells ranges from 15% to 22%, depending on the type of silicon used. Monocrystalline cells typically

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Solar Silicon Wafer Size M0 M2 G1 M6 M10 G12

Jan 8, 2024 · What do "M" and "G" stand for in solar wafer size? It begins with the letter "G", which means that the solar silicon wafer is full square Beginning

How many watts per kilogram of solar cell | NenPower

Aug 24, 2024 · The primary technologies employed in solar cells include silicon-based cells, thin-film cells, and emerging technologies such as perovskite and organic solar cells. Each type

Solar Panel Size & Weight: A Comprehensive Guide

Have you ever wondered how big solar panels are? Solar panel size range in a variety of sizes, factors such as solar cell type, total wattage and the type of panel all affect the overall size.

Microsoft PowerPoint

Feb 24, 2011 · Typical mono‐ and polycrystalline silicon solar cells (upper), and simplified cross‐section of a commercial monocrystalline silicon solar cell (lower) (© 2010 Sharp).

How To Calculate Solar Panel Output? – Glyde Solar

Modern solar panels are made of monocrystalline or polycrystalline silicon solar cells. Both produce equivalent amounts of energy, but monocrystalline panels use higher-grade silicon,

Installing Solar Systems in Panama

Jul 14, 2024 · What are solar panels? Solar panels, also known as photovoltaic (PV) panels, convert sunlight into electricity. They are composed of numerous solar cells made from

How Many Watts of Silicon Wafers Power Your Photovoltaic

Let''s start with a tasty metaphor: silicon wafers in solar panels are like pizza slices – their size, thickness, and quality determine how much energy you get. But instead of calories, we''re

Solar cell efficiency tables (version 57)

Nov 27, 2020 · World-record 20.6% efficiency 156 mm × 156 mm full-square solar cells using low-cost kerfless ultrathin epitaxial silicon & porous silicon lift-off

BR-041001 Crystalline Silicon_Catalog Layout

Laser-Based Manufacturing Processes on c-Si Solar Cells The use of lasers in making photovoltaic devices can both improve cell efficiencies and reduce overall manufacturing costs

60 Cell vs. 72 Cell Solar Panels: Which is Right

Aug 30, 2018 · There are many different types of solar panels available on the market, with options ranging in efficiency, wattage, manufacturer, appearance,

How Many Silicon Cells Are in a Solar Panel?

Apr 2, 2024 · In this section, we will analyze the silicon content in 1 kW solar panel batteries and tentatively estimate the silicon content of each that we are going to look into. One of the major

Silicon solar cells: toward the efficiency limits

Jun 5, 2023 · In this paper, we review the main concepts and theoretical approaches that allow calculating the e ciency ffi limits of c-Si solar cells as a function of silicon thickness. For a given

Silicon solar cells: materials, technologies, architectures

Jan 1, 2020 · A solar cell in its most fundamental form consists of a semiconductor light absorber with a specific energy band gap plus electron- and hole-selective contacts for charge carrier

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Monocrystalline silicon solar cells are more efficient than polycrystalline silicon solar cells in terms of power output. In order to increase

6 FAQs about [Wattage of Panama Silicon Solar Cells]

How many Watts Does a solar panel produce?

Residential solar panels typically range from 60 to 72 cells, providing power outputs between 250 and 400 watts. Commercial and utility-scale installations often employ larger panels with 96 or more cells to achieve higher power outputs, sometimes exceeding 500 watts per panel.

Can silicon solar cells improve power conversion efficiency?

Provided by the Springer Nature SharedIt content-sharing initiative Silicon solar cells are a mainstay of commercialized photovoltaics, and further improving the power conversion efficiency of large-area and flexible cells remains an important research objective1,2.

How many watts can a solar cell make?

Under standard conditions, a cell can make about 0.7 watts. Conditions are 1,000 W/m² sunlight, 25°C, and air mass 1.5. How can the power output of a single solar cell be calculated? To find a cell’s power, you multiply sunlight by cell efficiency. The formula is: Power Output = Solar Irradiance × Solar Cell Efficiency.

How much power does a solar panel make?

A single solar cell usually makes about 0.7 watts of power. This happens in normal test conditions. Conditions include bright sun, a temperature of 25°C, and atmospheric effects. The actual power made can change. It depends on the type of solar cell and the area’s weather. This info is key for figuring out how much power a solar panel can make.

Are thin-film solar panels better than crystalline silicon?

Thin-film panels are less efficient than crystalline silicon, with efficiencies around 7-13%, but they are lightweight, flexible, and can be produced at a lower cost. Residential solar panels typically contain 60 or 72 photovoltaic (PV) cells, though some smaller panels may have as few as 48 cells.

Are silicon solar cells a mainstay of commercialized photovoltaics?

Nature 626, 105–110 (2024) Cite this article Silicon solar cells are a mainstay of commercialized photovoltaics, and further improving the power conversion efficiency of large-area and flexible cells remains an important research objective 1, 2.

Learn More

- Wattage comparison between solar lights and LED lights

- Flexible monocrystalline silicon solar photovoltaic panels

- Panama Solar Lithium Battery Pack Introduction

- Solar cells with better energy storage

- Amorphous silicon solar inverter

- Polycrystalline silicon solar photovoltaic panel 1080x808

- Photovoltaic crystalline silicon solar panels

- Zambia Silicon Solar Panel Module

- Solar crystalline silicon photovoltaic panels

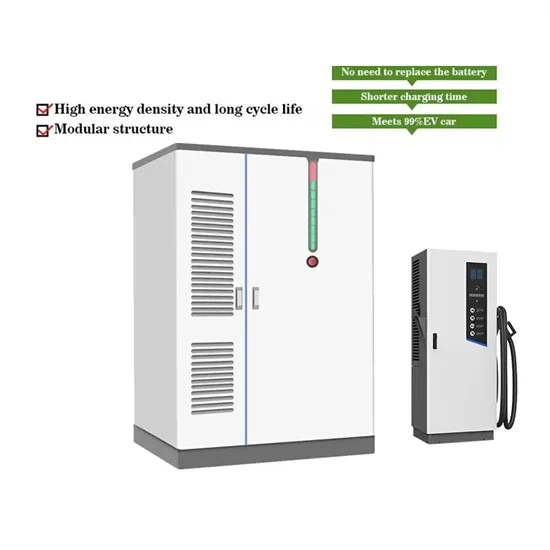

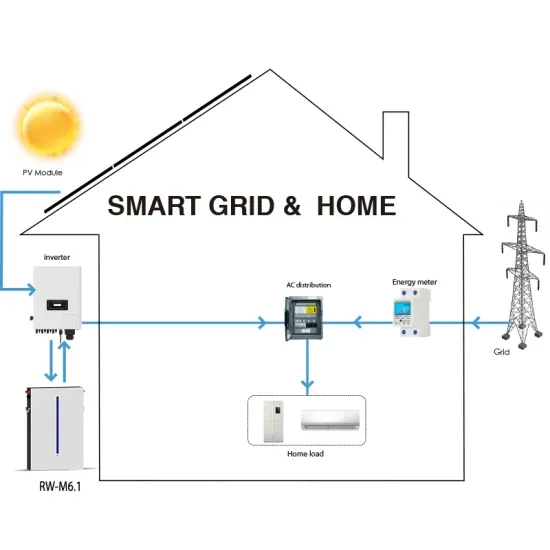

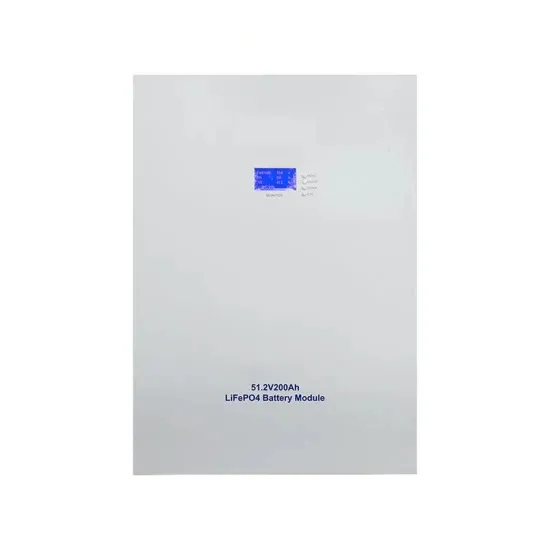

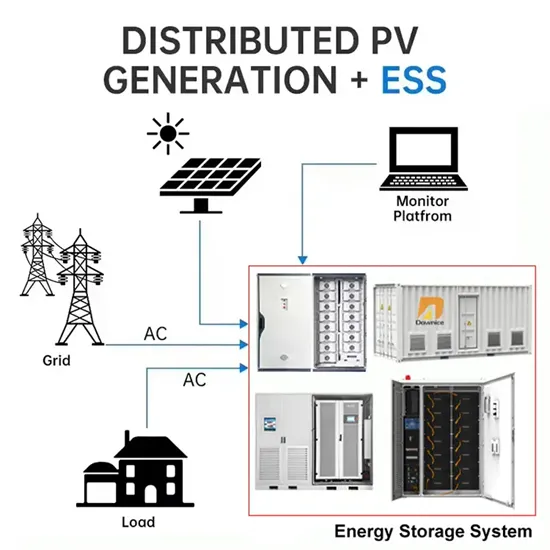

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.