The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Polycrystalline Solar Panels: What You Need To

Apr 17, 2024 · These polycrystalline solar panels hold a mosaic looking surface made up of numerous polycrystalline silicon. This is what makes these solar

Specifications and models of polycrystalline silicon

Sep 30, 2020 · Working Principle of polycrystalline solar panels: A polycrystalline solar panel is made up of several photovoltaic cells, each of which contains silicon crystals that serve as

Explained: Breaking Down the Solar Panel Triad –

Apr 25, 2025 · As solar energy adoption accelerates globally, understanding the differences between solar panel technologies is crucial for making informed decisions. The three primary

Monocrystalline vs. Polycrystalline Solar Cells

Dec 17, 2024 · Solar panels are composed of multiple solar cells, typically made from silicon or other semiconductors, which convert energy from sunlight into

How to Select the Best Polycrystalline Photovoltaic Panels

Choose poly panels with ≤0.15mm silicon cutting loss and oxygen-carbon ratio <1.0. Verify 17.5-19.2% STC efficiency using IV testers showing <2% deviation. Select 1.6mm anodized frames

Microsoft PowerPoint

Feb 24, 2011 · Crystalline and Polycrystalline Silicon PV Technology Crystalline silicon PV cells are used in the largest quantity of all types of panels on the market, representing about 90% of

Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · Monocrystalline photovoltaic panels are advanced devices designed to convert sunlight into electrical energy through a process called the photovoltaic effect. Their

Polycrystalline Solar Panel: Features, Working

Jun 15, 2024 · Polycrystalline solar panel working principle These solar panels are made of multiple photovoltaic cells. Each cell contains silicon crystals

Monocrystalline vs. Polycrystalline Solar Panels

May 5, 2023 · A solar panel is a composition of solar photovoltaic (PV) cells that absorb light from the sun and convert it into electricity. Typically, solar cells are made of silicon. There are two

China Polycrystalline Silicon Photovoltaic Panels

ORITRON is one of the most professional polycrystalline silicon photovoltaic panels manufacturers and suppliers in China. If you''re going to buy high quality polycrystalline silicon

Polycrystalline Solar Panel: Features, Working Principle,

Sep 19, 2024 · Polycrystalline or multi crystalline solar panels are solar panels that consist of several crystals of silicon in a single PV cell. Several fragments of silicon are melted together

What Is A Polycrystalline Solar Panel? | Definition, Cost,

Feb 11, 2025 · A polycrystalline solar panel, also known as a multi-crystalline solar panel, is a type of photovoltaic (PV) panel used to convert sunlight into electricity. These panels are

Monocrystalline, Polycrystalline, and Thin-Film

4 days ago · Difference Between Monocrystalline, Polycrystalline, and Thin-Film Solar Panels. Comparison Between Various Types of Solar Panels & Which

Polycrystalline solar panels: the expert guide [2025]

Jul 14, 2025 · In this guide, we''ll explain what polycrystalline solar panels are, how they''re made, and why they''ve fallen so far from their position as the most

Polycrystalline silicon | Solar Galaxy | 1300 339 596

Aug 11, 2025 · Polycrystalline silicon, often known as multicrystalline silicon, is a material composed of small silicon crystals or grains. This form of silicon is distinguished by its

What are polycrystalline silicon solar cells?

Sep 22, 2024 · In summary, polycrystalline silicon solar cells represent a crucial facet of the solar energy landscape, characterized by their unique advantages

Polycrystalline silicon solar cells

Jan 1, 2021 · The silicon demand for photovoltaic applications will be increased. The relations among the manufacturers of polycrystalline silicon with demand in the market from 2003 to

Monocrystalline vs Polycrystalline Solar Panels:

Apr 6, 2025 · As the global shift toward renewable energy accelerates, the choice between monocrystalline and polycrystalline solar panels emerges as a critical

Polycrystalline Silicon Solar PV Panels | U R Energy

Aug 10, 2025 · Go SOLAR, Go SAFE. Polycrystalline solar panels are easily installed and cared for. Browse our latest range of top quality polycrystalline silicon solar PV panels.

Polycrystalline silicon thin-film solar cells: Status and perspectives

Dec 1, 2013 · The present article gives a summary of recent technological and scientific developments in the field of polycrystalline silicon (poly-Si) thin-film solar cells on foreign

6 FAQs about [Polycrystalline silicon solar photovoltaic panel 1080x808]

What are polycrystalline solar panels?

The surface of these solar cells resembles a mosaic which comes under polycrystalline solar panel specifications. These solar panels are square in form and have a brilliant blue color due to the silicon crystals that make them up. These solar panels convert solar energy into power by absorbing it from the sun.

What is polycrystalline silicon?

Photovoltaic Energy Polycrystalline silicon plays a crucial role in solar energy production, particularly in the manufacturing of photovoltaic (PV) cells. There are two main types of photovoltaic panels: Monocrystalline panels – Made from single-crystal silicon, offering higher efficiency.

How are polycrystalline solar panels made?

The slabs of polycrystalline solar panels are created by melting several silicon shards together. The molten silicon vat used to make the polycrystalline solar cells is permitted to cool on the panel itself in this situation. The surface of these solar cells resembles a mosaic.

How do polycrystalline solar panels work?

Polycrystalline panels have a limited amount of electron movement inside the cells due to the numerous silicon crystals present in each cell. These solar panels convert solar energy into power by absorbing it from the sun. Numerous photovoltaic cells are used to construct these solar screens.

Can I buy a new polycrystalline solar system?

Polycrystalline solar panels now make up 0% of global production, so you almost certainly won’t find an installer offering to install a new polycrystalline system for any price. You can pay for used solar panels, but this is usually a bad idea.

What happened to polycrystalline solar panels?

As the International Energy Agency (IEA) wrote in 2024: “the transition to [monocrystalline] PV modules advanced in 2023, and [polycrystalline] disappeared from the market.” How are polycrystalline solar panels made? They’re made with polysilicon – hence the name – which is produced by heating up quartzite in temperatures of about 1,700°C.

Learn More

- Solar polycrystalline silicon photovoltaic panel manufacturers

- Monocrystalline silicon solar photovoltaic panel 400w

- 24V polycrystalline solar photovoltaic panel

- Cuban rooftop solar photovoltaic panel manufacturer

- Nauru Solar Photovoltaic Panel Source Manufacturer

- Angola Solar Photovoltaic Panel 13m x 24m

- How much does a 700W solar photovoltaic panel cost

- 20v20w solar photovoltaic panel

- Communication base station photovoltaic solar panel manufacturer

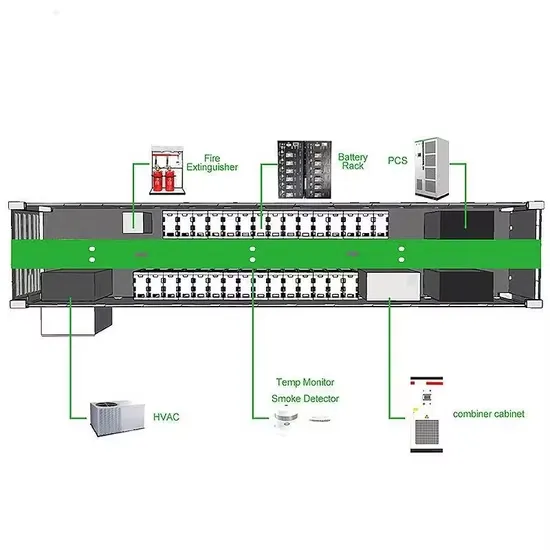

Industrial & Commercial Energy Storage Market Growth

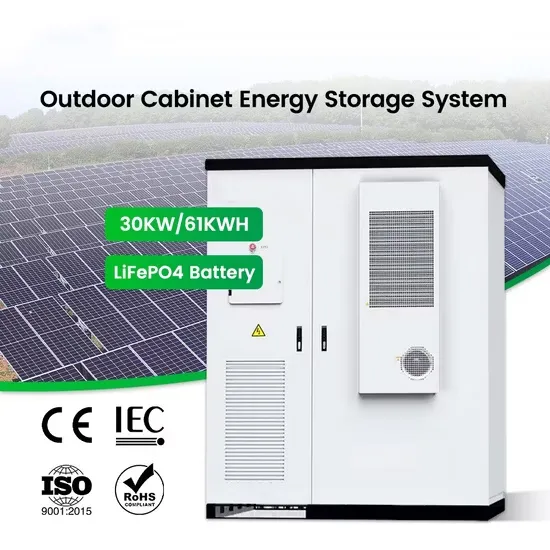

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.