Analysis of the degradation of amorphous silicon mini

Aug 24, 2023 · A sequential and extended tests were performed in our case on encapsulated amorphous silicon PV cells. The characteristics of the modules were monitored along the

Hybrid Solar System: How It Works and Its Benefits

Jun 27, 2024 · What is a Hybrid Solar System? A Hybrid Solar System contains solar panels, a hybrid inverter, and battery storage to create an uninterrupted

A Comprehensive Guide to Amorphous Silicon Solar Cells

Amorphous silicon solar cells offer a cost-effective and versatile alternative to traditional crystalline silicon technology. By using thin-film designs, advanced manufacturing, and innovative

Crystalline Silicon vs. Amorphous Silicon: the Significance of

Nov 21, 2020 · Firstly, the paper briefly introduces the structure of crystalline silicon, amorphous silicon, and hydrogenated amorphous silicon and highlights the structural differences. Then,

Environmental effects on a grid connected 900 W

Oct 1, 2011 · This study analyses the performance of a small scale, grid connected, thin-film amorphous silicon (a-Si) photovoltaic (PV) system located in Abu Dhabi. This investigation

Amorphous Solar Panel

Sep 7, 2021 · Constructed in a very similar fashion to the typical crystalline panels we''re so accustomed to seeing, amorphous solar panels offer highly efficient renewable energy at a

Holdings: Daily performance of kaneka g-sa060 amorphous silicon

Daily performance of kaneka g-sa060 amorphous silicon photovoltaic module based on solar irradiation and temperature in kangar malaysia as dc voltage source on spwm transformerless

The benefit of using p-a-SiOxCy:H as double window layers

2 days ago · n-type silicon solar cells with amorphous/crystalline silicon heterojunction rear emitter Parameters identification of the single-diode model for amorphous photovoltaic panels

Efficient and Flexible Thin Film Amorphous

Feb 10, 2017 · Thin-film amorphous silicon (a -Si:H) solar cells were subsequently constructed on the patterned PI flexible substrates. The periodic nanopatterns

Review: Progress in solar cells from hydrogenated amorphous silicon

Sep 1, 2017 · Hydrogenated amorphous silicon (a-Si:H) has played a crucial role therein—for decades already as intrinsic absorber layers with doped layers to build PIN junctions, and to

P‐9.2: ESL products with amorphous silicon solar cells

2 days ago · n-type silicon solar cells with amorphous/crystalline silicon heterojunction rear emitter Parameters identification of the single-diode model for amorphous photovoltaic panels An

Performance and Modeling of Amorphous Silicon

Oct 8, 2013 · CONCLUSIONS The 1-kW amorphous silicon PV roofing system has performed as expected, except for some minor inverter issues. The array appears to have stable performance.

Amorphous Silicon Solar Cells: Features and Applications

Oct 11, 2024 · Amorphous silicon solar cells have numerous benefits and applications in electronics, wearables, buildings, and more. Affordable, efficient, and flexible solar power

Amorphous and Nanocrystalline Silicon Solar Cells

Dec 16, 2016 · This chapter reviews some of the major thin silicon (Si) technologies, with emphasis on the amorphous silicon (a-Si:H) and nano-crystalline silicon (nc-Si:H) technology.

6 FAQs about [Amorphous silicon solar inverter]

What are amorphous silicon solar cells?

Amorphous silicon solar cells and other thin-film solar cells are the onl options available in terms of raw material availability when it comes to using sunlight t generate large amounts of electricity for human consumption. Big-scale production is simple

Are amorphous silicon thin film solar cells effective?

Amorphous silicon thin film solar cells’ poor efficiency and inconsistent performance are the main obstacles to their widespread industrial manufacturing, however, there are still many ways to make them more effective. The use of thin-film solar cells will be commonplace.

What is amorphous silicon?

Amorphous silicon (a-Si) i s a variant of silicon that lacks a defined crystalline structure. This material is used to manufacture solar cells and thin-film transistors integral to LCDs. Unlike crystalline silicon, amorphous silicon has a disordered structure that requires less silicon, making it cheaper to produce.

Are amorphous solar panels better than crystalline silicon?

Compared with crystalline silicon solar cells, panels made from amorphous silicon require less material, are more flexible and lighter, and are produced at lower costs, making them ideal for applications where flexibility and weight are critical.

Why are amorphous silicon solar cells ineffective?

The amorphous silicon structure’s long-range disordered random network topology greatly scatters the carriers, making it ineffective at efficiently gathering them. The conversion efficiency and stability of amorphous silicon solar cells are typically not improved by the monocrystalline silicon solar cells’ p-n structure.

What is an amorphous solar panel?

An amorphous solar panel operates on the same principle as a regular panel, using Si-based photovoltaic technology. However, instead of using individual cells made from Si wafers, it employs a thin layer of non-crystalline silicon that is applied to a substrate such as metal, glass, or plastic.

Learn More

- Solar power inverter silicon carbide

- Pure sine wave inverter amorphous

- Wholesale 500w solar inverter in Mongolia

- Solar Panel Inverter for Democratic Republic of Congo

- Do I need to buy an inverter when buying solar panels

- Cuba Solar Panel Inverter

- China 300 watt solar inverter in Zambia

- Aurora solar inverter factory in Brasilia

- Can the inverter be connected to solar panels

Industrial & Commercial Energy Storage Market Growth

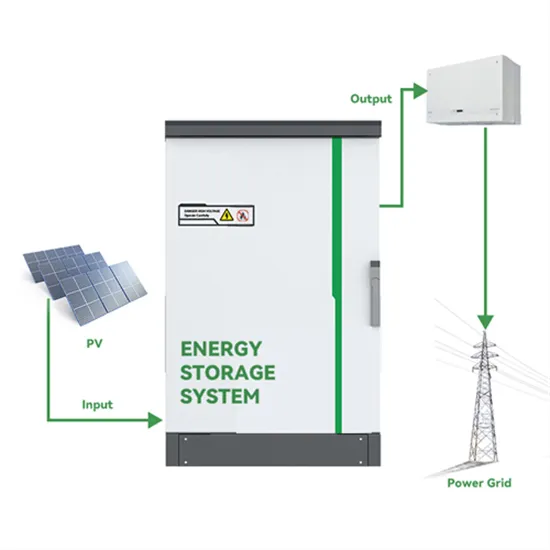

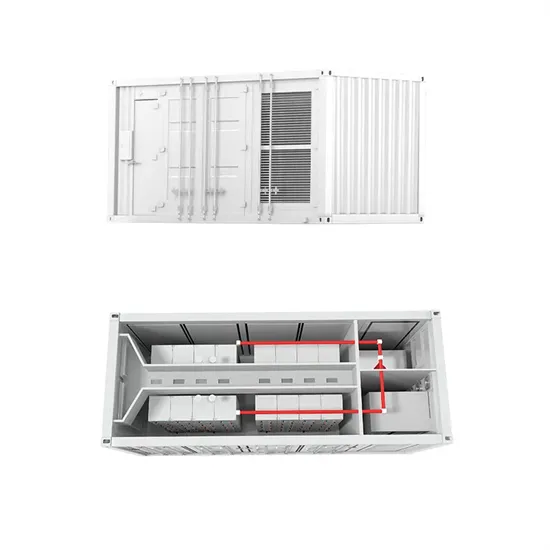

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.