Changes and challenges of photovoltaic inverter with silicon carbide

Oct 1, 2017 · Silicon carbide (SiC) devices can break through the technical limitations of silicon (Si) devices. Thus, SiC devices are considered as the foundations of next-generation high

Semiconductor technology in solar inverters: future

Mar 10, 2025 · Semiconductor technology in Solar Inverter s: future development trends 1. Current status of semiconductor technology in solar inverters 1.1 Application of traditional silicon-based

Solar Power Needs Silicon Carbide

May 14, 2021 · Regardless of where you put the solar farm, it needs a power electronic converter to tie it to the grid. The converter consists of an optional voltage boost stage and an inverter to

How solar inverters are cashing in on silicon

Jul 27, 2023 · Silicon carbide (SiC) power semiconductors, making headlines for their vital role in electric vehicle (EV) inverters and charging infrastructure

How Silicon Carbide is Changing Solar Power

May 28, 2020 · Silicon carbide enables solar inverters to be lighter, smaller and more efficient. Using silicon carbide power components instead of silicon for

How silicon carbide helps maximize efficiency in

Jan 19, 2024 · This translates to higher energy yields, which are imperative for maximizing the output of power converters in renewable systems such as solar inverters, energy storage

Industrial & Commercial Solar Systems | SiC

5 days ago · Industrial and commercial facilities often have expansive, flat roof space – an ideal location for installing large-scale solar systems to generate

Silicon Carbide in Solar Energy Systems: Improve Efficiency

Jul 23, 2025 · Silicon Carbide (SiC) is rapidly transforming solar energy technology by offering superior efficiency, reliability, and sustainability for modern photovoltaic (PV) systems. With

Silicon carbide photovoltaic cells

Si-rich-silicon carbide Photovoltaic Density functional theory ABSTRACT Silicon carbide has been used in a variety of applications including solar cells due to its high stability. The high bandgap

Silicon Carbide Is Changing the Game of Solar

Mar 11, 2020 · Image used courtesy of UnitedSiC The inverter that occupies the center-right portion of the illustration is best served through the employment of

The Rise of Silicon Carbide (SiC): Why EVs and Solar Inverters

Jun 27, 2025 · In summary, silicon carbide is revolutionizing the way we approach power electronics, particularly in electric vehicles and solar inverters. Its unique properties offer

Top Silicon Carbide (SiC) Wafer Suppliers: A Comprehensive

5 hours ago · Here''s a quick look at what they focus on: SiC Wafers: The basic building blocks for all SiC devices. EV Inverters: Key components for electric vehicles. Solar Inverters: Used in

Wolfspeed unveils cutting-edge silicon carbide module

Sep 23, 2024 · Wolfspeed, Inc. (NYSE: WOLF), the global leader in silicon carbide technology, today unveiled a silicon carbide module designed to transform the renewable energy, energy

How Wolfspeed silicon carbide is changing solar

Oct 20, 2023 · One specific area where silicon carbide has positively impacted the sustainability of solar power generation designs is in the design of highly

Silicon Carbide Semiconductors -The Next Key Technology

Jul 30, 2024 · For applications such as electric vehicles (EVs) and solar panels, silicon carbide (SiC) semiconductors are rapidly gaining traction as a technology that can enable necessary

Research of Solar Inverter Based on Silicon Carbide JFET Power

Jan 1, 2012 · Compared to silicon power devices, the silicon carbide power device is more suitable for solar power inverter due to its good electric characteristics. This paper presents

Silicon Carbide: Fueling the Green Energy Revolution

Jul 18, 2025 · Due to these properties, silicon carbide has become essential in any application dealing with high-power use and electronics: solar inverters, EVs, industrial power supply, etc.

Silicon Carbide in Solar Energy Systems: Improve Efficiency

Feb 12, 2025 · Silicon Carbide (SiC) is rapidly transforming solar energy technology by offering superior efficiency, reliability, and sustainability for modern photovoltaic (PV) systems. With

Why Sunsathi Solar Uses SiC MOSFET Over IGBT

Mar 25, 2025 · Sunsathi Solar uses SiC MOSFET over IGBT for higher efficiency, reduced power losses, and superior thermal management. This ensures better performance, reliability, and

Changes and challenges of photovoltaic inverter with silicon carbide

Oct 1, 2017 · Wilhelm C, Kranzer D, Burger B. Development of a highly compact and efficient solar inverter with silicon carbide transistors. In: Proceedings of International Conference on

Learn More

- Niue Solar Power Inverter

- Costa Rica Solar Power Inverter

- Does solar power have an inverter

- Off grid solar power inverter in Bahrain

- Solar inverter power supply system

- Power frequency solar off-grid inverter high power

- Off grid solar power inverter in Iran

- Paramaribo Solar Power Inverter

- Site requirements for solar power frequency inverter

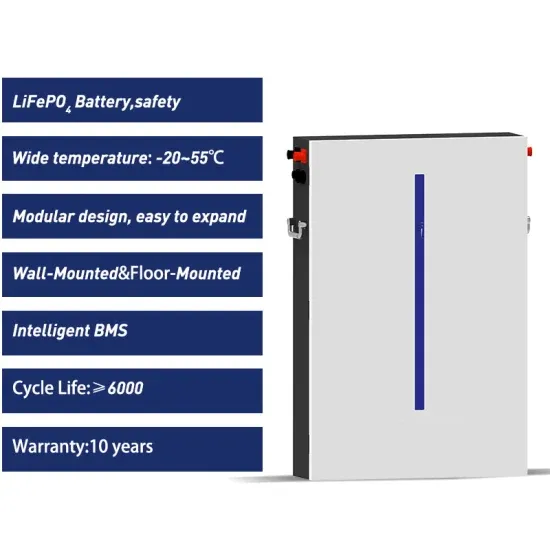

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

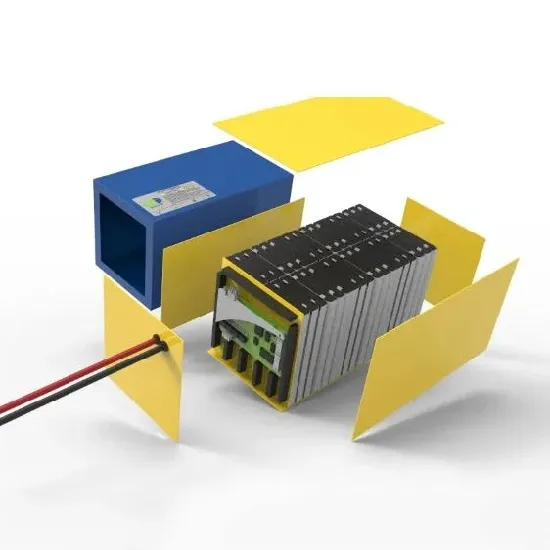

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.