"7 industrial uses for low voltage inverters"

Jan 4, 2023 · Low Voltage Inverter Used For Elevator and Lift Control In buildings with elevators and lifts, low voltage inverters are used to control the motor-driven systems responsible for

High-voltage VS Low-voltage Inverters: What''s the difference?

May 14, 2025 · Confused about high-voltage vs low-voltage inverters? This easy-to-read guide explains the differences, pros, cons, and real-world uses—perfect for anyone exploring solar

Amazon : YAFODUTE High Power Pure Sine Inverter Voltage

Pure Sine Wave Inverter : The car inverter converter adopts pure sine wave technology, which has low interference, low noise and large load capacity, it is a voltage converter that converts

How many volts is suitable for solar inverter

Jul 31, 2024 · To determine the appropriate voltage for a solar inverter, one must consider several factors that directly influence the inverter''s performance and

Inverter Basics: Classification and Applications

Jan 3, 2021 · Inverter Basics: Resonant Inverters This is the class of inverters in which output voltage or current is passed though zero to minimize switching

Inverter vs converter: What''s the difference?

Mar 29, 2024 · Key differences between inverters vs converters The fundamental difference between inverters and converters can be found in their functionality. Converters change the

480V Inverters from DC to AC: An Industrial Guide | Mingch

Aug 6, 2025 · Learn about 480V inverters from DC to AC for industrial use. This guide covers applications, challenges, and key features of high-voltage power conversion.

48V to 60V Inverters Applications Efficiency and Industry

This guide explores their technical advantages, real-world applications, and how they optimize energy conversion for industries like renewable energy, electric vehicles, and industrial

Can a 48V inverter be used when plugged into a 60V inverter

Using a 60V inverter with a 48V system is technically possible, but it comes with several risks and considerations:Overheating: Operating a 48V motor at 60V can lead to overheating

48V Inverter: The Ultimate Guide to Efficient and Scalable

May 19, 2025 · Yes, for the most part. 48V inverters are generally more efficient and have thinner wiring, which means less energy loss and lower installation costs. 48V inverters can also

小功率修正弦波逆变器-英文打印版

Apr 8, 2021 · Special power cord (optional) 48V/60V/72V Inverter Use an electric bicycle battery The inverter with the input voltage of 48V/60V/72V can be powered by the electric bicycle

Can all inverters use lithium batteries?

Nov 28, 2023 · Many modern inverters are designed to work seamlessly with both traditional and alternative battery technologies. It''s also important to dispel the myth that all inverters require

Power voltage inverter in uninterruptible and autonomous

It''s also important to note that power inverters can be used in uninterruptible power supply setups. They can provide long-term power supply stability and can even work seamlessly with other

6 FAQs about [Can 48v60v voltage inverters be used universally ]

Do I need a 12V or 48V inverter?

Simply put, if you have a 12V system, you need a 12V inverter; a 48V system requires a 48V inverter. Standard Pure Sine Wave inverters simply change DC power to AC power. Inverter Chargers handle this function plus allow you to charge your batteries off shore power or a generator. Renogy’s 3500W Solar Inverter Charger is designed for a 48V system.

Do 48V power inverters work?

48V power inverters work perfectly in 48V solar systems, which are usually either small commercial or large residential. These inverters are typically paired with 48V PV modules and batteries of a comparable voltage.

What is a 48V low frequency inverter?

The Advantages of 48V Low Frequency Inverters 48V low frequency inverters have proven to be highly efficient in converting DC power to AC power. With their advanced technology and design, they minimize energy losses, resulting in optimal performance and reduced electricity bills.

How to maintain a solar inverter 48V?

Solar inverter 48V needs a cool dry place where sunlight doesn’t reach it. The electronics inside it are very vulnerable, so learn to take good care of it. These simple measures will prolong the lifespan of your inverter: If you are looking for an inverter 48V, we have a variety of different models in our store.

Can a 48V inverter be rated at 2 kVA?

In this post I have explained a simple 48V inverter circuit which may be rated at as high as 2 KVA. The entire design is configured around a single IC 4047 and a few power transistors. I am a big fan of u....i am a wisp. i need an inverter design with 48volt DC input and 230volt output supply and output power in the range up to 500w.

Can a 48 volt inverter run a battery?

When you use a 48-Volts inverter, you can use regular and more flexible connectors to connect the inverter to the battery bank. This is so because the thinner the wire, the higher the resistance. And if your DC voltage is lower, you will pass more current through the wires, and they can get very hot, and you lose a lot of battery power.

Learn More

- Can 24V inverters be used universally

- Are inverters afraid of unstable voltage

- Can matrix batteries be used with inverters

- Can micro grid-connected inverters be used

- Can photovoltaic panels with a voltage difference of 1 volt be used together

- Can ordinary inverters be used off-grid

- Multiple photovoltaic panels connected to inverters

- What are the inverters for household appliances

- Best wholesale 1500 watt inverters Wholesaler

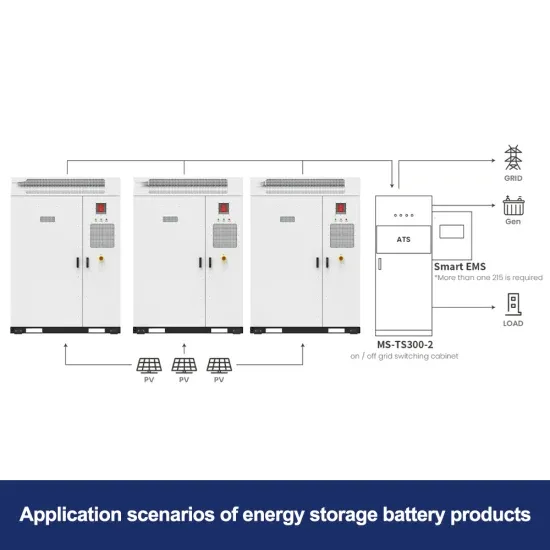

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.