Can I Use a 24V Inverter on a 12V Battery?

Again you can connect 12V batteries in a series to match a 24V solar array or inverter. Benefits of 24V Inverters and 24V Batteries To keep it simple, if you are in an RV or any motorhome, use

24 volt inverter recommendations? | DIY Solar Power Forum

Feb 21, 2021 · Looking for new 24 volt inverter. 2000 watt. Presently looking at the Giandel. Any recommendations? Also I could swear I have seen a combo 12v/24v inverter somewhere but

Can 12V and 24V Inverters Be Used Interchangeably A

May 12, 2025 · Ever wondered if your 12V inverter can handle a 24V system? Let''s break it down. While both 12V and 24V inverters convert DC to AC power, their voltage compatibility

What Is An Inverter? | Definition, Types, Uses,

Jan 25, 2025 · High-quality inverters, particularly those used in solar power systems or industrial applications, can last longer with proper care. Factors

The Differences Between 24v and 48v Inverter:

Apr 13, 2025 · The correct inverter voltage is essential for system efficiency, safety, and future scalability. In standard off-grid solar systems, RVs, or mobile

Can Victron Phoenix 24V inverter be used with 12volt battery?

Apr 28, 2024 · Does this mean I can buy the 24V inverter and use it my 12V battery since it says Voltage 8.6-34V in the manual? From what I can tell the price of 12V and 24V are almost the

What is a 24V UPS Inverter and How Does It Work

Mar 12, 2025 · Which Applications Benefit Most from 24V UPS Inverters? 24V UPS inverters are widely used in telecom base stations, small data centers, industrial control systems, and off

What Are the Alternatives If You Need to Use a 24V Inverter

Oct 28, 2024 · Is a 24V inverter better than a 48V? Whether a 24V inverter is better than a 48V inverter depends on your specific needs. 48V inverters typically offer higher efficiency and can

12V vs 24V Inverter: What''s The Difference & Which is Better

Frequently Asked Questions 1. Can I use a 12V inverter with a 24V battery? No, you cannot directly use a 12V inverter with a 24V battery. Inverters are designed to match the voltage of

Can I Use A 24V Inverter With A 12V Battery? Compatibility

Feb 7, 2025 · Using a 24V inverter with a 12V battery is not recommended. This voltage mismatch can create power limitations and pose safety hazards. For an effective solar energy system,

Can I Connect a 12V Inverter to a 24V Battery Bank

Jun 3, 2025 · However, converters can add complexity and minor energy losses, so consider whether upgrading to a 24V inverter might be better. Can I use a 24V inverter on a 12V battery

Tips to Choose the Right Inverter for Homes:

Sep 27, 2023 · Choose the Right Inverter with the difference between 12V or 24V and their advantages: inverter efficiency, battery bank setup, cabling cost, and

Frequently Asked Questions about Inverters

Dec 11, 2024 · 12V Inverters: Common in small setups but less efficient because they need higher current, leading to more energy loss as heat and voltage drops. 24V Inverters: More efficient in

24v Inverter, 24v DC to 120v/240v AC Power Inverter

The power inverter can convert 24V DC to 110V/120V or 220V/230V AC. Equipped with a USB port, the 24V inverter can be used for multi-purpose charging. 24V inverter has multiple safety

Can I Run A 12V Inverter On A 24V Battery? Solutions And

Feb 6, 2025 · To use a 12V inverter with a 24V battery, a DC-DC buck converter can be employed. This device reduces the 24V input down to 12V for the inverter, ensuring safe and

How to Connect Two Inverters in Parallel: A

Nov 9, 2024 · Connecting two inverters in parallel can significantly increase your power output, making it a popular choice for solar energy systems and backup

Understanding the Compatibility of 12V Solar Panels with 24V

Apr 7, 2025 · The rise of renewable energy sources has sparked a significant interest in solar power, with many people seeking to harness the sun''s energy for personal and commercial

6 FAQs about [Can 24V inverters be used universally ]

Are 24V inverters a good choice?

24V inverters offer a significant advantage in terms of battery efficiency. Because the system operates at a higher voltage, the current draw is lower, which reduces the strain on the battery bank and prolongs battery life. This makes 24V inverters a better choice for larger systems or those that require long-lasting power.

Can a 12V inverter run on a 24v battery?

If you try to use a 12V inverter on a 24V battery it will be overloaded. Contrastingly, using a 24V inverter with a 12V battery will lead to a lack of electrical force. Knowing your inverter's voltage and what that means is critical in order for everything to run correctly.

What is the difference between a 12V and 24V inverter?

The difference between a 12V and 24V inverter is the amount of input volts it can handle. This is the voltage flowing from the battery into the inverter before the electricity is converted from DC to AC. So a 12V inverter is designed for 12 volts input from the battery. And a 24V inverter is designed for 24 volts input from the battery.

What are the benefits of using a 24V inverter?

This improved efficiency translates into energy savings, longer battery life, and potentially smaller system components. For instance, a 2400W inverter would require 200A at 12V but only 100A at 24V, significantly reducing wire size and cost.

What is a 24V inverter?

24V Inverters: These systems generally offer higher efficiency, particularly in larger installations, thanks to lower current demands and reduced wire losses. This improved efficiency translates into energy savings, longer battery life, and potentially smaller system components.

Does a 12V inverter need a battery bank?

The battery bank you use will play a crucial role in how long your system can run before needing a recharge. 12V vs 24V inverters have different effects on battery life and capacity. 12V inverters typically require a larger battery bank to provide enough power for extended periods.

Learn More

- Can 48v60v voltage inverters be used universally

- Can photovoltaic inverters be used indoors

- Can ordinary inverters be used off-grid

- How big a photovoltaic panel should be used to charge a 24v lithium battery

- What are the inverters used in photovoltaics

- Commonly used voltages for photovoltaic inverters

- Are 24v and 20a inverters compatible

- Factory price 3000w inverters in Kuwait

- China factory price 3000w inverters exporter

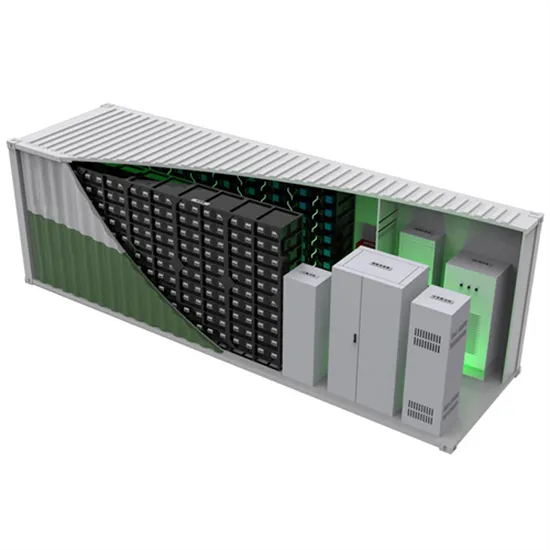

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

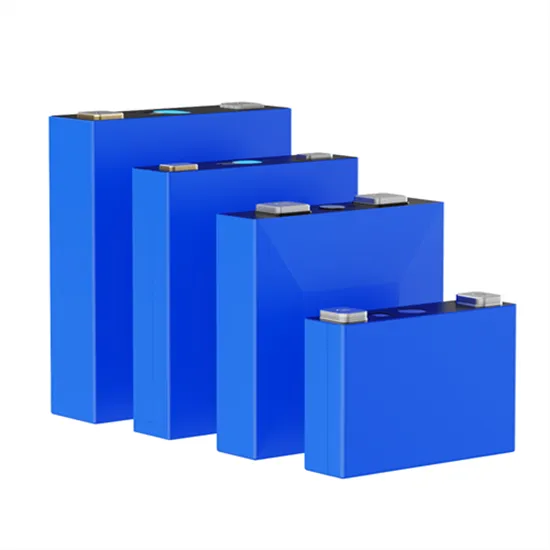

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.