Voltage change of series-connected photovoltaic panels

When solar panels are wired in series, the voltage of the panels adds together, but the amperage remains the same. So, if you connect two solar panels with a rated voltage of 40 volts and a

Solar Panel Voltage: Guide to Getting the Best

Feb 27, 2025 · Typical voltage specifications for different solar panel types Series vs. Parallel: How to Connect Your Panels The way you connect your solar

Solar Panel Voltage: Guide to Getting the Best

Feb 27, 2025 · Solar panel voltage is basically how much electrical pressure your panels produce. Think of it like water pressure in a pipe – higher voltage

How To Wire Solar Panels In Series Vs. Parallel

Wiring in parallel allows you to have more solar panels that produce energy without exceeding the operating voltage limits of your inverter. Inverters also have amperage limitations, which you

Does the voltage of a solar panel have to be greater than

Jul 16, 2025 · I have a 6 volt solar panel and a 4.8 v battery pack(4 AA nimh). Will I be able to charge the pack? The solar panel is 100 milliamps and batteries 2300 mah.The solar panel is

Can You Mix Different Voltage Solar Panels?

Jul 11, 2024 · Technically, yes, you can mix different voltage solar panels; however, it is not recommended. It takes careful configuration to ensure the panels work together instead of

Panels with slightly different voltage

Jul 17, 2021 · Most of the 100W panels I can find have a Vmp of ~18.6V. Four of these in series gives 74.4V. If the roof mounted panels are shaded, but still producing something, would

Introduction to Photovoltaic Solar Energy | SpringerLink

May 25, 2024 · The chapter provides a thorough overview of photovoltaic (PV) solar energy, covering its fundamentals, various PV cell types, analytical models, electrical parameters, and

Photovoltaic Panels Parallel vs. Series Connection

Dec 5, 2023 · What is the parallel connection of photovoltaic panels? Parallel connection of photovoltaic panels involves connecting all their cables on the

Solar PV energy: From material to use, and the most commonly used

Nov 1, 2022 · Generation of electricity from the sun can be achieved using solar PV (SPV) systems or through concentrating solar-thermal power (CSP) systems that drive conventional

wiring different voltage panels in parallel

Aug 22, 2016 · I''m cool with the bottle neck that was created with trying to wire two panels with different current in series. What I''m trying to explain is why when two different voltage solar

Difference in photovoltaic panel voltage

Step 1: Note the voltage requirement of the PV array Since we have to connect N-number of modules in series we must know the required voltage from the PV array. PV array open-circuit

How Voltage and Current Work Together in Solar Energy

Sep 12, 2024 · When we talk about solar energy systems, we''re diving into a fascinating convergence of voltage and current that makes harnessing the sun possible. Imagine you''ve

6 FAQs about [Can photovoltaic panels with a voltage difference of 1 volt be used together ]

Do solar panels produce a higher voltage than nominal voltage?

As we can see, solar panels produce a significantly higher voltage (VOC) than the nominal voltage. The actually solar panel output voltage also changes with the sunlight the solar panels are exposed to.

What are the different solar panel voltages?

Namely, we have to come to terms with the fact that there are several different voltages we are using for solar panels (don’t worry, all of these make sense, we’ll explain it). These solar panel voltages include: Nominal Voltage. This is your typical voltage we put on solar panels; ranging from 12V, 20V, 24V, and 32V solar panels.

Are solar panels rated higher than system voltage?

The solar panels are of voltage rating higher than the system voltage. You have two different higher voltage solar panels, i.e., one 100W/24V and one 200W/24V that you want to connect to the already working 12 V solar power system comprising the two 12V 50 W solar panels connected in parallel from the previous scenario (see the picture above).

What is a solar panel voltage & how does it work?

Let’s break it down in simple terms. Voltage is the push behind the electricity that flows through your solar panels. Speaking of panels, every solar panel has a certain voltage output. Keep in mind that this output might vary based on factors like sunlight, temperature, and the number of solar cells in the panel.

Do solar panels produce a high voltage?

Keep in mind that this output might vary based on factors like sunlight, temperature, and the number of solar cells in the panel. Open Circuit Voltage: When your solar panel isn’t connected to any devices, you get the highest voltage a panel can produce.

Can you mix different solar panels?

Mixing solar panels of various voltage or wattage, or produced by different manufacturers, is a frequently asked question by most DIYers. Though mixing different solar panels is not recommended, it’s not forbidden and things would be ok as long as each panel’s electrical parameters (voltage, wattage, amps) are carefully considered.

Learn More

- The difference between photovoltaic panels and power generation panels

- Do photovoltaic panels have voltage in weak light

- The difference between photovoltaic and solar panels

- 16 550w photovoltaic panels output voltage

- Price difference between monocrystalline and polycrystalline photovoltaic panels

- Color difference of single crystal photovoltaic panels

- 24 volt battery charging photovoltaic panels

- The difference between single glass and double glass panels for photovoltaic panels

- The difference between photovoltaic panels and batteries

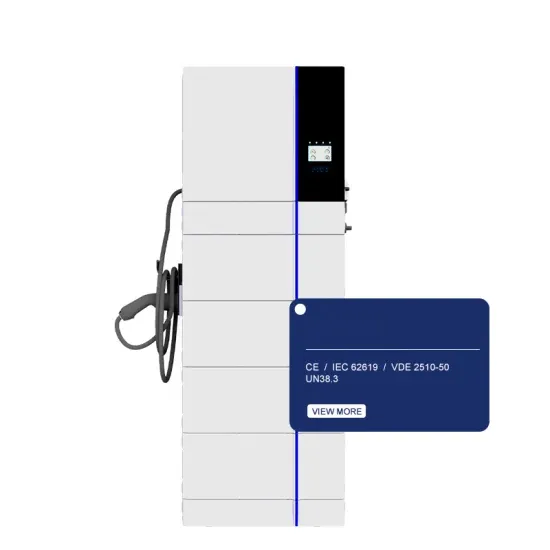

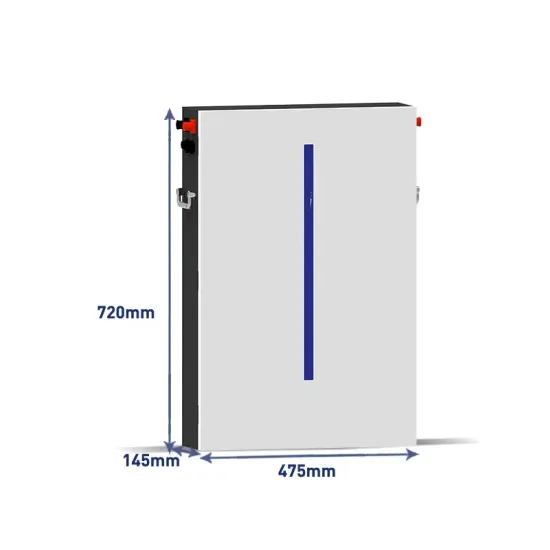

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.