Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · Twenty years ago, papers described that the design of electric vehicles (EVs) could change due to the limits of lead/acid batteries [4]. Studies and experiments provided

Lithium battery pack and lead acid battery who is better

Mar 25, 2019 · In fact, there is no absolute certainty about this problem. In terms of perspective, lead-acid batteries and lithium batteries occupy the dominant position. The following small

A comparative life cycle assessment of lithium-ion and lead-acid

Jul 15, 2022 · The lithium-ion batteries have fewer environmental impacts than lead-acid batteries for the observed environmental impact categories. The study can be used as a reference to

Vanguard™ Lithium-Ion vs. Lead Acid Batteries

2 days ago · It''s time to harness a sustainable, in-demand power source. However, selecting the right battery pack for an application can be challenging, with various factors to consider, such

Battery Pack – Aa Lithium Energy

Jan 21, 2025 · A battery pack is a collection of individual batteries or cells assembled together to provide power to electronic devices, vehicles, or systems. They are designed to deliver a

A Complete Guide to Understanding Battery Packs

Jul 24, 2024 · Battery packs come in many types, each suited to different needs and applications. Whether it''s for a smartphone, electric vehicle, or a portable

Active Cell Balancing of Lithium-ion Battery Pack Using Dual

Jan 1, 2021 · An auxiliary lead-acid battery is used to provide energy for cell balancing during discharging period instead of taking power from entire battery pack as typically used in P2C

How to Understand and Prevent Reverse Polarity in Batteries

2 days ago · Reverse polarity in batteries occurs when you connect the battery terminals incorrectly, causing current to flow in the wrong direction. This can create serious safety risks,

Are Battery Packs Lithium?

Apr 25, 2025 · While alternatives like nickel-cadmium and lead-acid batteries still serve certain applications, lithium-ion technology remains the most versatile, reliable, and efficient choice for

Test and Measurement of Lead-Acid and Lithium Battery Packs

Oct 27, 2023 · Nowadays, electrochemical battery storage systems are so important in both stationary and mobile applications, especially for telecommunication fields. The lead-acid

Lithium-ion vs. Lead Acid Batteries | EnergySage

Dec 20, 2023 · In this article, we''ll compare two of the most common battery options paired with solar installations: lithium-ion and lead acid. Other than the

Lithium vs Lead Acid Batteries: A Simple Guide for Buyers

6 days ago · Lithium vs Lead-Acid: Lithium lasts longer and is lighter, but costs more. Lead-acid is cheaper upfront but heavier. Choose based on your budget and needs.

Lithium Iron Phosphate Battery Packs: Powering the Future

Apr 22, 2025 · For example, traditional lead - acid batteries contain toxic lead, and some lithium - ion batteries with cobalt - based cathodes have raised environmental and health concerns due

6 FAQs about [Lithium battery pack and lead-acid battery pack]

What is the difference between lithium-ion and lead-acid batteries?

Lead-acid batteries typically use heavy lead plates and sulfuric acid, while lithium-ion battery systems rely on lightweight lithium compounds and organic electrolytes, offering higher efficiency and energy stored. How does battery capacity compare between lead-acid and lithium-ion?

Is it safe to replace lead acid batteries with lithium-ion batteries?

Yes, it is generally safe to replace lead acid batteries with lithium-ion batteries in marine and RV applications. However, it is important to consider compatibility with the specific application and follow proper installation and handling procedures.

What are lead acid batteries?

Lead acid batteries are rechargeable batteries that use lead and sulfuric acid to generate electricity. They consist of lead plates immersed in sulfuric acid, facilitating a controlled chemical reaction to produce electrical energy.

Are lithium ion batteries better than lead acid batteries?

In contrast, lithium-ion batteries have the advantage of faster charging times. This is because lithium-ion battery chargers deliver a constant current charge, allowing for higher charging currents. As a result, the charging time for lithium-ion batteries can be significantly shorter compared to lead acid batteries.

What is the difference between lithium iron phosphate and lead acid batteries?

Here we look at the performance differences between lithium and lead acid batteries The most notable difference between lithium iron phosphate and lead acid is the fact that the lithium battery capacity is independent of the discharge rate.

How much does a lead acid battery system cost?

A lead acid battery system may cost hundreds or thousands of dollars less than a similarly-sized lithium-ion setup - lithium-ion batteries currently cost anywhere from $5,000 to $15,000 including installation, and this range can go higher or lower depending on the size of system you need.

Learn More

- Lead-acid battery parallel lithium battery pack

- 60v lead-acid lithium battery pack

- Which lithium battery pack is cheaper in New York USA

- Assemble 15a lithium battery pack

- Bishkek battery pack lithium battery container

- 37 23kwh lithium battery pack in Bergen Norway

- Zhongke lithium battery pack

- Tonga 12v lithium battery pack

- Lithium battery pack judgment

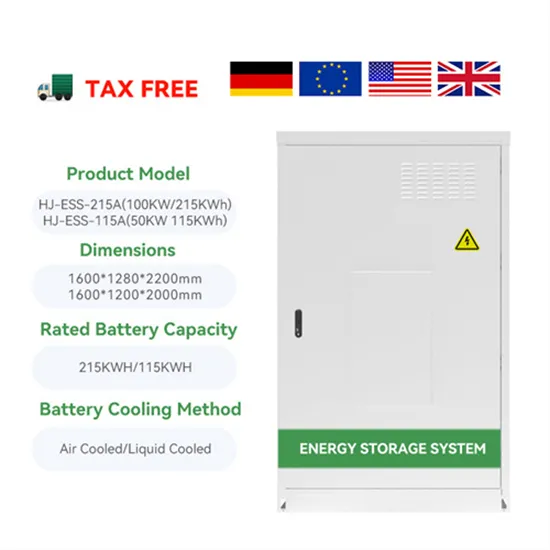

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.