Exploring the Advantages of Modular Lithium Battery Packs

Mar 10, 2025 · In recent years, the demand for efficient energy storage solutions has seen a significant surge, prompting advancements in battery technology. Among the most promising

Are Battery Packs Lithium? Explore Portable Chargers, Safety,

Dec 27, 2024 · Most battery packs, especially portable chargers, use lithium-ion batteries. These batteries are efficient and lightweight, which suits portable devices.

What Are the Disadvantages of a Lithium-Ion Battery?

Lithium-ion batteries face challenges like thermal runaway risks, limited lifespan (300-500 cycles), high production costs, environmental concerns from mining/cobalt use, and temperature

Advantages and Disadvantages of Lithium-ion Batteries – en

Jan 14, 2024 · There are many advantages to using a Li-ion cell. As a result, the technology is being used increasingly for a huge number of widely varying applications. A lithium-ion battery

Core Disadvantages of Lithium-Ion Battery Technology

Jun 11, 2025 · Safety Vulnerabilities Thermal Runaway Risk: Internal short circuits from physical damage or manufacturing defects can trigger uncontrolled temperature spikes exceeding

Advantages & Limitations of the Lithium-ion Battery

Mar 27, 2020 · The lithium-ion battery Pioneer work with the lithium battery began in 1912 under G.N. Lewis but it was not until the early 1970s when the first non-rechargeable lithium batteries

Advantages and disadvantages of lithium-ion batteries

Jan 1, 2025 · Despite the technology''s potential, LIBs still have a number of disadvantages. High voltages can damage LIBs and cause them to overheat. Major issues have resulted from this,

Integration issues of lithium-ion battery into electric vehicles

Feb 1, 2016 · In this work, the integration of Lithium-ion battery into an EV battery pack is investigated from different aspects, namely different battery chemistry, cell packaging, electric

Core Disadvantages of Lithium-Ion Battery Technology

Jun 11, 2025 · Emerging Alternatives Addressing Li-ion Limitations Solid-State Batteries: Eliminate liquid electrolytes to mitigate flammability while enabling 400+ Wh/kg density Lithium-Titanate

Lithium-Ion (Li-ion) Batteries: Advantages, Disadvantages,

Aug 9, 2025 · Disadvantages of Li-ion Batteries. Costs ~30-50% more than lead-acid batteries. Overcharging, punctures, or extreme heat can cause fires/explosions. Requires Battery

Lithium-Ion (Li-ion) Batteries: Advantages, Disadvantages,

Aug 9, 2025 · Lithium-Ion (Li-ion) Batteries: Advantages, Disadvantages, Sizes & Applications Introduction Lithium-ion (Li-ion) batteries have revolutionized modern electronics, electric

Understanding Lithium-Ion Battery Packs: A Beginner''s Guide

Aug 9, 2024 · Lithium-ion (Li-ion) battery packs are essential components powering a wide range of modern technologies, from smartphones and laptops to electric vehicles and renewable

advantages and disadvantages of the lithium-ion battery

2020-01-31 CTECHi 393 Huizhou JB Battery Technology Co., Ltd. is one of the leading manufacturers of customized lithium-ion battery packs in China and is able to design and

The Advantages of Portable Lithium Battery Packs

Nov 27, 2024 · In recent years, the shift towards renewable energy storage and efficient power solutions has accelerated, particularly with the rise of lithium technology. These advanced

Understanding the Disadvantages of Lithium-Ion Batteries

Feb 10, 2025 · One significant disadvantage of lithium-ion batteries is their limited lifespan. Typically, these batteries can endure anywhere between 500 to 1,500 charge cycles,

How Do Lithium-Ion Battery Packs Work and Why Are They

Nov 12, 2024 · Lithium-ion battery packs are crucial components in many modern devices, providing reliable power with high energy density. They operate by moving lithium ions

A review on the liquid cooling thermal management system of lithium

Dec 1, 2024 · Lithium-ion batteries (LIBs) are gradually becoming the choice of EVs battery, offering the advantages of high energy storage, high power handling capacity, and long life

What are the advantages and disadvantages of lithium battery

The advantages of lithium battery packs have good high temperature function: the peak heat of lithium iron phosphate battery packs can reach 350℃-500℃, and the operating temperature

Are Rechargeable Battery Packs Lithium? Types, Uses, and

Mar 29, 2025 · Rechargeable battery packs are often lithium-ion. These battery packs can be recharged multiple times, offering a longer lifespan and better value. In contrast, lithium battery

Are Battery Packs Lithium?

Apr 25, 2025 · But why has lithium become the gold standard in battery technology? From powering smartphones and laptops to running electric vehicles and power tools, lithium battery

Advantages and Disadvantages of Lithium Polymer Batteries

Advantages Use of these batteries provides the lipo battery manufacturer a competitive advantage over the others. Because, not only are these rechargeable but also, they can be

6 FAQs about [Disadvantages of lithium battery packs]

What are the disadvantages of a lithium-ion battery?

Lithium-ion batteries face challenges like thermal runaway risks, limited lifespan (300-500 cycles), high production costs, environmental concerns from mining/cobalt use, and temperature sensitivity. They degrade faster in extreme heat/cold and require complex management systems.

What are the risks associated with lithium batteries?

Different industries face unique risks depending on how lithium batteries are used. Electric Mobility: Large batteries in EVs are particularly susceptible to mechanical damage during accidents. Manufacturing: Mishandling during production or assembly may trigger internal shorts.

What happens if a lithium battery goes bad?

Storing lithium batteries near heat sources, direct sunlight, or hot machine parts can cause them to heat up beyond safe operating temperatures. This can destabilize internal components, increasing the risk of fire even when the battery isn’t in use. The more energy a battery stores, the greater the risk it poses in case of failure.

Are lithium ion batteries sustainable?

Lithium-ion batteries face limitations such as high costs, thermal instability, limited lifespan, and environmental concerns. They degrade over time, require precise charging protocols, and pose fire risks under extreme conditions. Recycling infrastructure remains underdeveloped, complicating sustainability efforts.

What are the environmental risks of Mining lithium ion batteries?

Mining lithium, cobalt, and nickel involves ecological disruption, water pollution, and CO 2 emissions. Less than 5% of lithium-ion batteries are recycled due to complex chemistries and costs. Landfill disposal risks toxic leakage. Emerging hydrometallurgical recycling methods promise higher recovery rates but remain energy-intensive.

Are lithium ion batteries safe?

Lithium-ion cells and batteries are not as robust as some other rechargeable technologies. They necessitate protection against overcharging and excessive discharge. In addition to this, they want to have the present day maintained inside secure limits.

Learn More

- 5 12v lithium battery packs

- How many lithium battery packs are needed for 60v

- Can lithium battery packs be checked in

- Do lithium battery packs need voltage division

- Where to assemble lithium battery packs in Macedonia

- Do lithium battery packs need additional containers

- 42 lithium battery packs in 14 strings

- How many strings are there of 21 volt lithium battery packs

- How many amperes are there in 40 lithium battery packs of 36v

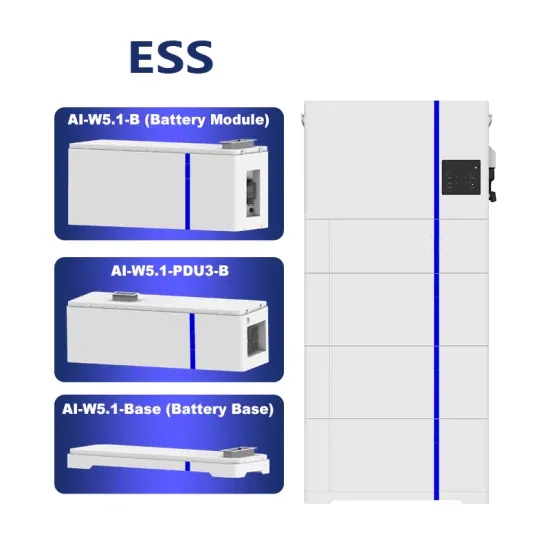

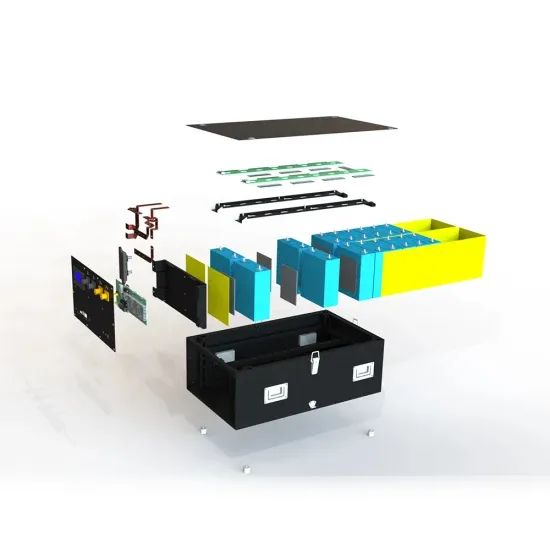

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.