Tembesi Floating Solar: A Comparative Study of Monofacial and Bifacial

Nov 6, 2024 · The design and simulation of a Floating Photovoltaic Power Plant (FPVPP) using both monofacial and bifacial PV modules are covered in this paper. It highlights

Dominance of PV, the shift to bifacial back contact c-Si

4 days ago · Radovan Kopecek and Joris Libal examine the technological and economic factors driving PV''s ascendancy, with emphasis on bifacial BC modules.

Bifacial solar photovoltaics – A technology review

Jul 1, 2016 · Bifacial solar photovoltaics (PV) is a promising mature technology that increases the production of electricity per square meter of PV module through the use of light absorption

Bifacial PV System Performance

Oct 2, 2019 · • Bifacial PV is becoming mainstream with GW''s of installed projects • Energy gain depends on the site configuration and surface albedo. Models like SAM, PVSyst and

(PDF) Innovative floating bifacial photovoltaic

Dec 7, 2020 · Results of the thermal study showed that partially soaking the frame of PV modules into water does not bring a considerable additional yield

Tembesi Floating Solar: A Comparative Study of Monofacial and Bifacial

Nov 6, 2024 · The design and simulation of a Floating Photovoltaic Power Plant (FPVPP) using both monofacial and bifacial PV modules are covered in this paper. It highlights the potential

Project design > Bifacial Systems

Nov 7, 2024 · The Bifacial tool is available in the "System" part. It is only available (visible) when you choose a bifacial module. Bifaciality Factor Nowadays more and more Si-crystalline

Bifacial PV modules & systems

Apr 27, 2021 · Bifacial photovoltaic cells, modules, and systems are rapidly overtaking the market share of monofacial PV technologies. This is happening due to new cell designs that have

Understanding Bifacial PV Modeling: Raytracing and

Jan 30, 2020 · Bifacial performance modeling The PV industry is set for rapid uptake of bifacial PV if key barriers are eliminated accurate performance models, standards around the rating of

Bifacial Solar Photovoltaic Modules

Bifacial modules represent a promising technology for increasing a PV system''s lifetime generated electricity. Their core innovation is the ability to capture and utilize light from both sides of the

A systematic literature review of the bifacial photovoltaic module

Aug 12, 2024 · Bifacial photovoltaic (PV) technology has received much interest, with the International Technology Roadmap for Photovoltaic (ITRPV) projecting a market share of 85%

Empirical analysis of bifacial photovoltaic modules in high

Feb 1, 2025 · This paper presents a comprehensive empirical analysis of bifacial photovoltaic (bPV) module performance in high-latitude regions, based on data colle

Bifacial Photovoltaics 2021: Status, Opportunities

Dec 11, 2020 · In this paper we summarize the status of bifacial photovoltaics (PV) and explain why the move to bifaciality is unavoidable when it comes to

Thermal comparison of floating bifacial and monofacial photovoltaic

Jul 1, 2025 · The overall performance of PV modules is significantly affected by the design configuration, especially the bifacial module technology over the conventional monofacial

Agenda 55th PVPS ExCo Mtg

Apr 27, 2021 · Bifacial photovoltaic cells and modules Bifacial photovoltaic cells, modules, and systems are rapidly overtaking the market share of monofacial PV technologies. This is

Bifacial vs monofacial grid-connected solar photovoltaic for

Feb 1, 2023 · The grid connected bifacial solar farm is a better option with more energy potential, higher GHG abatement potential, and lower LCOE. The bifacial solar farm can provide

A comprehensive review and outlook of bifacial photovoltaic

Nov 1, 2020 · Results show that bPV modules outperform mPV and perform better with the increment of albedo and the reduction of ground shading. An outdoor bPV experiment also

Solar cell demand for bifacial and singulated-cell

Jun 16, 2017 · In this issue of Photovoltaics International Fraunhofer ISE presents a concept for a bifacial, shingled cell technology that it claims tracks a cost

6 FAQs about [Island photovoltaic bifacial modules]

What is bifacial photovoltaic (PV) technology?

Bifacial photovoltaic (PV) technology (cells and modules) can absorb light simultaneously from the front and rear sides. 1 This feature brings important advantages concerning monofacial PV technology: (1) lower land-use for the same watt-peak installation, (2) lower levelized cost of electricity (LCOE), and (3) smoother daily power profile.

Why are bifacial photovoltaic cells becoming more popular?

Bifacial photovoltaic cells, modules, and systems are rapidly overtaking the market share of monofacial PV technologies. This is happening due to new cell designs that have replaced opaque, monolithic back surface foil contacts with isolated contacts, which allow light to reach the cell from the rear side.

How do bifacial solar modules work?

Bifacial modules collect solar energy from both the front and back side of the module, increasing the total power output per module. LONGi had scaled up high-volume manufacturing of bifacial modules and has become the largest producer of bifacial PV products, with cumulative shipments of bifacial modules surpassing 20GW in early 2021.

Should bifacial solar farms be used in small islands?

The bifacial solar farm can provide cheaper option for grid integrated solar PV occupying a smaller land area, which is scarce in small islands. Sustainable Energy Industry Association of the Pacific Islands 1. Introduction

How many bifacial PV modules are there?

Systems 1 through 3 at each site have four monofacial and four bifacial PV modules, and systems 4 and 5 contain two monofacial and two bifacial modules. Each module is grid-connected by a microinverter and monitored for DC current and voltage.

Are bifacial PV modules degraded?

Degradation due to potential differences has been seen in bifacial PV modules based on different types of bifacial solar cells: n-type , and p-type , . The frame, glass, encapsulant, and other module packaging components can play an im-portant role in the extent of PID of PV modules.

Learn More

- Monocrystalline single-sided and bifacial photovoltaic modules

- Stockholm Island Photovoltaic Panel Prices

- Major export companies of photovoltaic modules

- Price of local photovoltaic modules in Vietnam

- Price of photovoltaic p-type modules

- Differences between bifacial modules and double-glass modules

- Bissau import and export of photovoltaic modules

- Heterojunction photovoltaic modules and BC cells

- Failure modes of solar photovoltaic modules

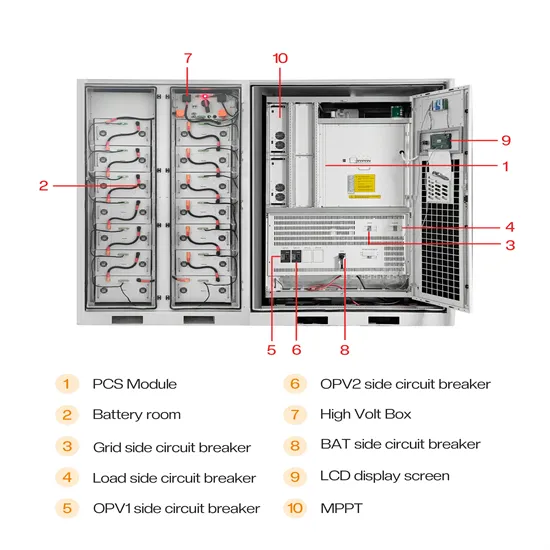

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.