Degradation and Failure Modes in New Photovoltaic Cell

Feb 23, 2025 · Degradation and Failure Modes in New PV Technologies Impact of Innovation on Degradation: Cell cracking issues are mitigated by multi-wire technology. LeTID is addressed

Failure Risk Analysis of Photovoltaic Systems Based on

Aug 5, 2025 · This paper highlights the most critical photovoltaic failure modes using the Failure Mode Effect and Criticality Analysis (FMECA) methodology. A review of the current knowledge

Degradation and Failure Modes in New Photovol

Jun 30, 2025 · con Hetero-Junction (SHJ) is shown in Figure 1 for selected degradation and failure modes. Especially semiconductor-related degradation modes show degradation and

Photovoltaic Failure and Degradation Modes

ABSTRACT The extensive PV field reliability literature was analyzed and reviewed. Future work is prioritized based upon information assembled from recent installations and inconsistencies in

Why Do PV Modules Fail?

Jan 1, 2012 · The solar irradiation heats the modules, the high-energy part of the solar irradiation, the ultra-violet irradiation, can cause chemical reactions and degradation processes inside the

Failure Mode Analysis and Detection Methods in

Based on this review, several failure modes are selected for analysis based on their relevance, focusing on three main components: PV modules, inverters, and cabling. Subsequently, a

Different Degradation Modes of PV Modules: An Overview

Sep 17, 2022 · This chapter is organized in two parts, the first of which shows the major degradation modes for failure of PV modules and second part describes the extent of these

Failure modes of silicon heterojunction photovoltaic

Aug 3, 2025 · Failure modes of silicon heterojunction photovoltaic modules in damp heat environment: Sodium and moisture effects Lucie Pirot-Berson, Romain Couderc, Romain

Degradation and Failure Modes in New Photovoltaic Cell

Feb 23, 2025 · The original PV failure fact sheets (PVFS 2021) were reviewed to include failures occurring in new module technologies and its impact in the field:

Failure Modes and Effects Analysis (FMEA) of a Rooftop

May 21, 2025 · In case of rooftop PV system the panels are mounted on the rooftop using suitable mounting structures. PV systems are classified by their rated power output (the peak power

A comprehensive review on failure modes and effect analysis of solar

Jan 1, 2023 · The performance and reliability of solar PV systems over its expected life is a key issue as the failure and degradation increase the cost of energy produced (Rs/kWh). This

Failure Modes and Effects Analysis of Polycrystalline Photovoltaic

Feb 14, 2024 · Failure Modes and Effects Analysis (FMEA) are crucial in ensuring the photovoltaic (PV) module''s long life, especially beyond 20 years with minimum operating costs. The diverse

Risk priority number for understanding the severity of photovoltaic

Dec 1, 2019 · The main objective of the present study is to overview defects occur in PV modules during the outdoor operation and to quantify their impacts on the PV module performance.

A Review of Photovoltaic Module Failure and

Aug 18, 2024 · This paper conducts a state-of-the-art literature review to examine PV failures, their types, and their root causes based on the components of PV modules (from protective

Four failure modes in silicon heterojunction glass-backsheet modules

Aug 1, 2023 · For economical and sustainability reasons, photovoltaic (PV) modules should continue to output over 80% of their initial performance for at least 25 years, and ideally 50

Failure modes of silicon heterojunction photovoltaic modules

Dec 1, 2024 · Silicon heterojunction (SHJ) solar cells are expected to gain significant market share in the coming years. In the field, among identified degradation modes, moisture-induced

Failures of Photovoltaic modules and their Detection: A Review

May 1, 2022 · Here, the present paper focuses on module failures, fire risks associated with PV modules, failure detection/measurements, and computer/machine vision or artificial

Detect, Decouple, Optimise: Insights into Solar Photovoltaics

2 days ago · This study integrates fault detection and diagnosis with long-term performance analysis for over 300 PV system strings. By decoupling reversible operational faults from

A Review of Photovoltaic Module Failure and Degradation

Jan 9, 2024 · This paper conducts a state-of-the-art literature review to examine PV failures, their types, and their root causes based on the components of PV modules (from protective glass to

Failure mode and effect analysis for photovoltaic systems

Oct 1, 2015 · So far, the most of the photovoltaic-related reliability analysis has focused on modules [1] and balance of system (BOS) separately [2]. Only in recent years the shift of focus

6 FAQs about [Failure modes of solar photovoltaic modules]

How to identify the severity of failure modes in solar PV systems?

The risk priority analysis is considered one of the promising approaches for identifying the severity of failure modes. The study reports shows that the inverter and ground system has a failure mode with high RPN. Table 1 summarizes various faults related to solar PV systems as reported in the literature studied. Table 1.

What happens if a PV module fails?

The hotspot failure mechanism is considered the most severe failure and leads to catastrophic consequences. It deteriorates all PV module components if undetected, and a PV module affected by an elevated level of hotspots cannot reverse the degradation and often requires replacement.

Which PV module failure modes are most relevant?

The PV module failure modes that stood out as the most relevant include PID (50), shading (24), bypass diode failure (24) and junction box overheat-ing (24). Figure 2 presents a chart depicting these failure modes in the PV module with the highest RPN, which helps visualize and highlight the criti-cal failure modes.

What are the degradation and failure modes of PV encapsulants?

The main degradation and failure modes of PV encapsulants include discolouration and delamination, such as in Fig. 5. Additionally, encapsulants are often partly responsible for degradation of other module components by facilitating or mediating degradation modes such as corrosion or potential induced degradation (PID) [25, 61, 104, 114, 115].

Does failure affect the reliability of solar PV systems?

The failure of the components affects the reliability of solar PV systems. The published research on the FMEA of PV systems focuses on limited PV module faults, line-line contact faults, string faults, inverter faults, etc. The literature shows that the reliability analysis method is used to evaluate different faults in PV systems.

How to reduce the degradation of PV modules?

To reduce the degradation, it is imperative to know the degradation and failure phenomena. This review article has been prepared to present an overview of the state-of-the-art knowledge on the reliability of PV modules.

Learn More

- Ultra-white solar glass photovoltaic modules

- Sources of solar photovoltaic modules in Maputo

- Structure of flat-plate solar photovoltaic modules

- Downstream products of solar photovoltaic modules

- Accra rural household solar photovoltaic modules

- Super large photovoltaic panels for construction site solar street lights

- Photovoltaic energy storage cabinet solar product price

- Solar photovoltaic panels 680 a set of 56 pieces

- Building balcony solar photovoltaic panels

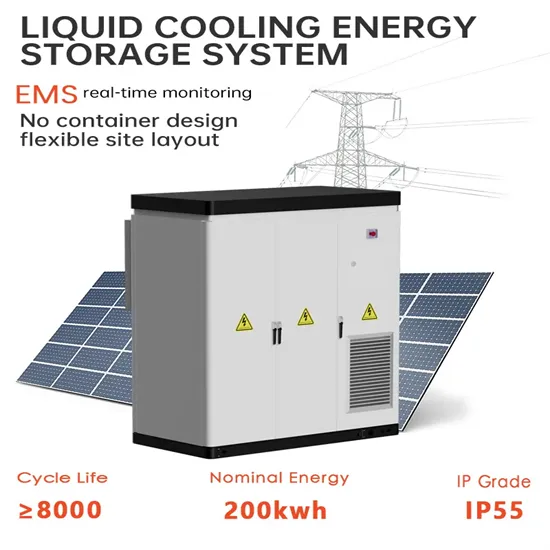

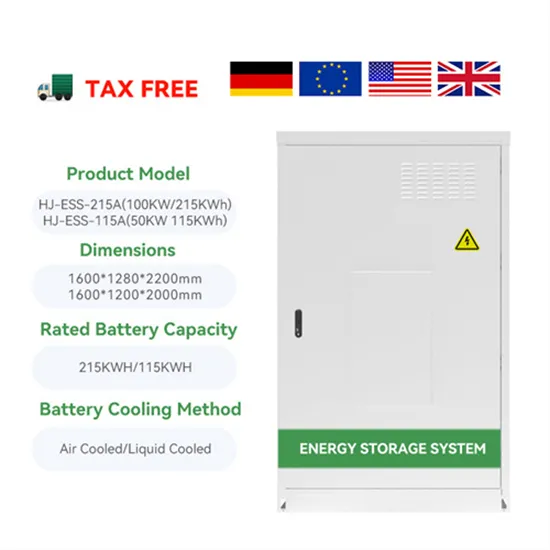

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

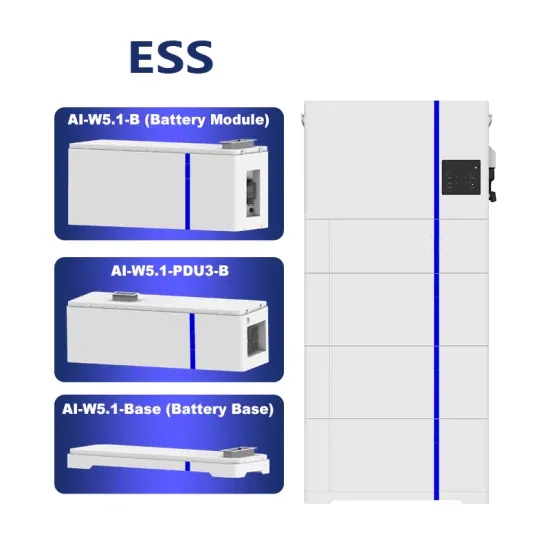

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.