The Impacts and Interaction of Upstream and

Solar Photovoltaic Industries of China Wang Hongwei30, Zhang Kai31, and Vanessa Yanhua Zhang32 Abstract try in China and aim to study the incentive correlation and interaction

Quantifying the accelerated diffusion and cost

Jan 17, 2025 · Summary Solar photovoltaic (PV) is critical for achieving the 2030 global target of tripling renewable power capacity. Over the past two decades,

Empirical analysis and strategy suggestions on the

Aug 1, 2019 · Around photovoltaic industry, Hongwei Wang et al. used the quarterly data of solar PV companies listed between 2009 and 2015 in China to conduct an empirical analysis of the

Photovoltaic inverter upstream and downstream

What are the stages of the upstream solar PV value chain? stages of the upstream solar PV value chain include all industrial steps starting from the production of polysilicon, crystalline silicon,

75% of European solar manufacturers focus on cells and

Mar 6, 2025 · Europe''s solar manufacturing sector heavily favours downstream products such as cells and modules, with 75% of European manufacturers involved in their production, so

Downstream Activities: Project Development, Distribution,

Downstream activities consist of distribution (wholesale) and physical installation. There is a large number of wholesalers, most of whom do not operate at globally. Some wholesalers have

Upstream and downstream enterprises of photovoltaic

What''s the difference between a midstream and a downstream PV industry? The industry''s midstream produces batteries, cell components, and related products. The downstream is an

Crystalline Silicon Solar PV Module Market Size & Growth

Aug 18, 2025 · Global Crystalline Silicon Solar PV Module Market size is predicted to reach USD 5431.28 million by 2033 from USD 3528.05 million in 2024, registering a CAGR of 4.41%.

Global PV Module Market Analysis and 2025

Dec 11, 2024 · PV modules are the central component of the solar industry. This analysis reviews market conditions that affect solar panel pricing and availability.

Sector supply-chain guidance – solar ener

Mar 10, 2025 · dia Rest of world Europe Source: IEA (2022b). While the production of downstream components such as modules, cells and, to a lesser extent, wafers has increased

China''s photovoltaic industry will remain bearish in 2025

Feb 7, 2025 · Polysilicon, refined from silicon metal, is the primary raw material for silicon-based solar cells and a critical component of the PV supply chain. Solar-grade polysilicon, with a

Market dynamics, innovation, and transition in China''s solar

Mar 1, 2017 · Manufacturing trends can partially explain the patterns of solar installations. PV modules are now mass produced, and the production of PV modules in large-scale fabrication

Policy-driven transformation of global solar PV supply chains

Jul 22, 2025 · Cui et al. find that open trade policy is a key factor for achieving low-cost solar photovoltaic supply chains. This conclusion holds even for regions, like Europe, that seek to

PHOTOVOLTAIC MODULES AND INVERTERS

Mar 5, 2025 · Solar PV accounted for three-quarters of renewable capacity additions worldwide in 2023 [1] and as per IEA, 6% of global electricity generation came from PV in that year [2]. As

Trinasolar produces world''s first fully recycled c-Si module, a

Sep 24, 2024 · To date, Trinasolar has delivered more than 225 GW of solar modules worldwide. In addition, Trina''s downstream business includes solar PV project development, financing,

Downstream solar meets upstream innovation at PV

Oct 23, 2019 · Operators from the upstream and downstream end of the solar scale descended on the two-day conference this week, organised by PV Tech publisher Solar Media, to check the

BUILDING RESILIENT GLOBAL SOLAR PV SUPPLY CHAINS

Jun 29, 2023 · The extreme concentration of the solar PV supply chain presents multiple risks, geopolitical and economic. The development of local solar PV manufacturing across the globe

Empirical analysis and strategy suggestions on the

Aug 1, 2019 · China is the largest energy consumer in the world and the leader in the solar photovoltaic industry [[16], [17], [18]]. The development of China''s photovoltaic industry is a key

An overview of the comprehensive utilization of silicon-based solid

Jun 1, 2021 · From a downstream perspective, the vigorous development of PV cell industry has greatly contributed to the rapid growth of PV module industry. The most intuitive manifestation

How circular is the European photovoltaic industry? Practical

Apr 5, 2024 · Although the shift to renewable energy is essential to combat the climate crisis, the current linear economic model in the European photovoltaic (PV) industry creates increasing

Sector supply-chain guidance – solar ener

Mar 10, 2025 · Sector supply-chain guidance – solar energy Environmental and social risk management toolkit for financial intermediaries Sector supply-chain guidance – solar energy 1.

The technological system of production and innovation: The

May 1, 2019 · It defines six main patent groups for the PV system: (i) solar cells, (ii) solar panels, (iii) electronics, (iv) monitoring and testing, (v) energy storage, and (vi) portable devices for

6 FAQs about [Downstream products of solar photovoltaic modules]

Does Europe's solar manufacturing sector favour downstream products?

Europe’s solar manufacturing sector heavily favours downstream products such as cells and modules, according to SolarPower Europe.

What are the effects of upstream PV industrial policies on downstream products?

In general, (1) For the impacts of upstream PV industrial policies on the downstream products, the policy-conducting effects are not obvious, that is, one unit of price drop due to the subsidy for the upstream PV enterprises leads to 0.016-unit price drop of downstream products, which is mainly due to the nature of the PV industry in China.

What's the difference between a midstream and a downstream PV industry?

The industry’s midstream produces batteries, cell components, and related products. The downstream is an integration of the PV installation system. China's PV industry that produces silicon of high purity relies on foreign countries for raw materials, key technology and equipment, and market demand.

Does China support the development of solar photovoltaic (PV) industry?

China has issued a series of policies to support the development of the solar photovoltaic (PV) industry and to help domestic solar PV enterprises.

What is the policy of China's solar PV upstream enterprises?

Source: Compiled by the authors. According to Figure 8.9, the main policy subject of China's solar PV upstream enterprises is the government, which sets fiscal policies, tax policies, and other policies (technical research and development, input and pollution compensation, etc.) based on the developing environment and trends.

Where does solar PV production come from?

lity2.1. Production and supply-chain contextOver the past two decades, most of the first-generation solar PV supply chain has moved to China, w ere the majority of production is now hosted. Even though demand is growing worldwide, China accounts for the lion’s share of the production

Learn More

- Ultra-white solar glass photovoltaic modules

- Sources of solar photovoltaic modules in Maputo

- PVDF film for solar photovoltaic modules

- Ngerulmud Distributed Solar Photovoltaic Modules

- Accra rural household solar photovoltaic modules

- Solar Photovoltaic On-site Energy Wireless Network

- Photovoltaic solar light integrated board

- Bosnia and Herzegovina Photovoltaic Folding Container Solar Air Conditioner

- Ghana solar panels photovoltaic power generation

Industrial & Commercial Energy Storage Market Growth

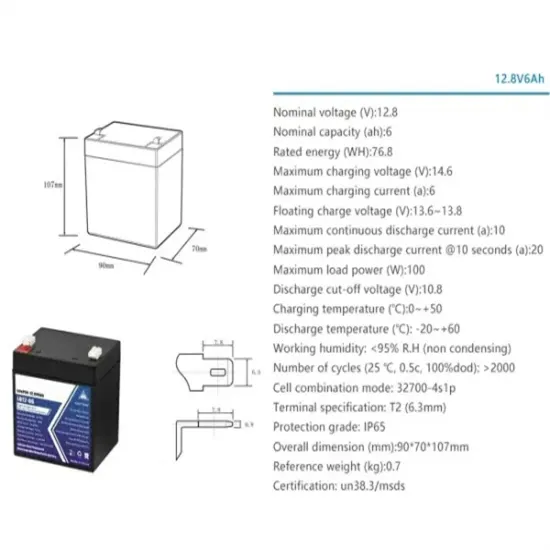

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.