Solar Panel Backsheet PET PVDF TPT for PV Module Production

Jun 23, 2025 · buy solar panel backsheet PET, PVDF, TPT sheets for solar module production from China tier 1 brand solar panel back sheet manufacturing factory supplying cheap low

Pyrolysis Gas Analysis of Ethylene-vinyl Acetate (EVA) and

Mar 14, 2024 · A detailed analysis of the gases evolved during pyrolysis of the End-of-Life (EOL) crystalline silicon photovoltaic (c-Si PV) solar module, focusing on recycling strategies has

PVDF Fluoropolymer Extruded Films

Oct 14, 2020 · Due to their excellent dielectric performance, fire resistance and high solar transmittance PVDF films are very well suited for use in the back sheet and front sheet glazing

A study of degradation mechanisms in PVDF-based

Dec 4, 2023 · The PVDF-based backsheets examined in this study were extracted from PV modules (fielded modules), mini-modules (C-AST and MAST), and laminated coupons (single

How to Enhance PVDF Functionality in Solar Cells?

Current research focuses on several key areas to further enhance PVDF functionality. These include optimizing PVDF nanostructures to improve light trapping and charge collection,

Development of Transparent Self-Cleaning Coatings for Solar

Aug 30, 2024 · The purpose of this study was to develop a self-cleaning and antireflective coating for commercial solar panels using low surface energy materials such as PVDF (Polyvinylidene

When Proven Performance Matters | Tedlar® PVF film

4 days ago · DNV-GL (Det Norske Veritas Germanischer Lloyd) performed an independent test for reliability of commercial PV modules with PVDF, PET and DuPont Tedlar® PVF-based

Poly(vinylidene fluoride)/Mica nanocomposite: A potential

Feb 1, 2022 · Solar backsheet is the protective layer of the photovoltaic module that plays a vital role in protecting the module from harsh environmental conditions. Various properties such as

Reliability and durability comparison of PV module

May 21, 2024 · For PV module manufacturers, a major challenge is choosing a low-cost backsheet that can maintain the current levels of high reliability and durability performance.

PVDF Film for PV Backsheet Market Size, Research, Market

Global PVDF Film for PV Backsheet Market Size By End-User Industry (Solar Energy, Consumer Electronics), By Type of Application (PV Backsheets for Photovoltaic Modules, Insulation

Boost Solar Durability with PVDF Encapsulation

Jul 15, 2025 · With inherent weather and corrosion resistance, PVDF is widely used in solar backsheets. Further modification can enhance its UV-blocking capacity and mechanical

Transparent backsheets for bifacial photovoltaic (PV) modules

Oct 1, 2021 · Maintaining the reliability of photovoltaic (PV) modules in the face of rapidly changing technology is critical to maximizing solar energy''s contribution to global

The Critical Role of PVDF in Solar Panel Backsheets

PVDF films exhibit water vapor transmission rates below 2 g/m²/day, protecting sensitive solar cell components from humidity-induced degradation. This moisture resistance is crucial for

3 FAQs about [PVDF film for solar photovoltaic modules]

Why should you choose TCI PVDF films?

TCI’s PVDF films offer excellent weatherability, chemical and abrasion resistance, non-stick properties, and superior dielectric performance, combined with excellent processibility of conventional thermoplastic materials. PVDF films can be heat-sealed, thermoformed, and laminated to various substrates.

What is PVDF used for?

Due to its superior chemical resistance to most acids and solvents, PVDF films are used as a contact surface for the production, storage and transfer of corrosive fluids, and find their applications in chemical tank linings, pump diaphragms, water treatment, and chemical storage bags.

What are DuPont® Tedlar® PVF film-based backsheets?

DuPont™ Tedlar® PVF film-based backsheets have and continue to maximize durability and reliability and minimize system defects.

Learn More

- Failure modes of solar photovoltaic modules

- Structure of flat-plate solar photovoltaic modules

- Sources of solar photovoltaic modules in Maputo

- Ngerulmud Distributed Solar Photovoltaic Modules

- Chromium telluride thin film photovoltaic modules

- How much does Lobamba photovoltaic solar panels cost

- New house solar photovoltaic panels for home use

- Belize Photovoltaic Solar Monitoring Power Supply System

- Solar panels photovoltaic power generation in Equatorial Guinea

Industrial & Commercial Energy Storage Market Growth

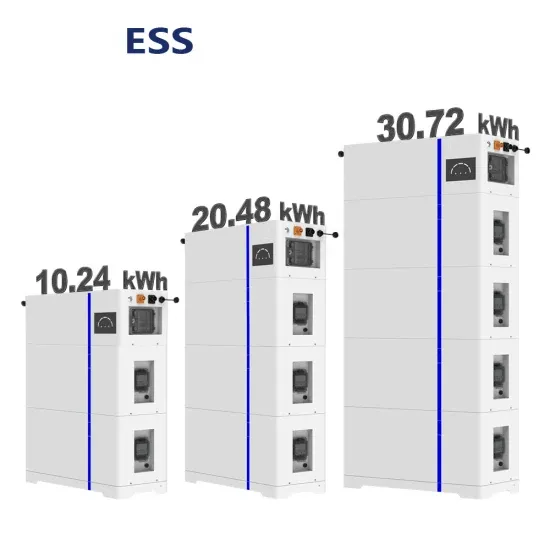

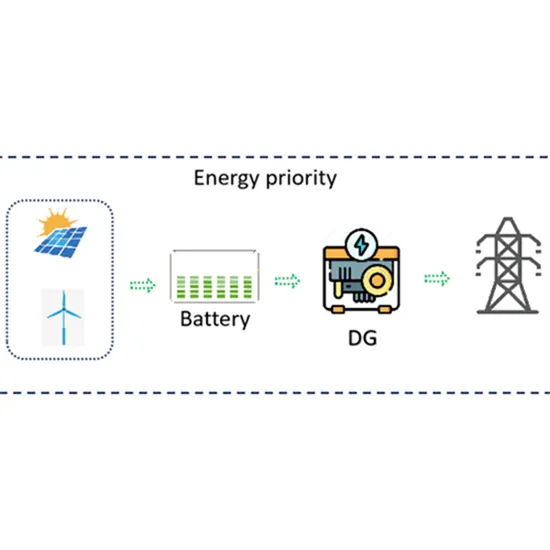

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.