Flat plate solar photovoltaic–thermal (PV/T) systems: A

Nov 30, 2015 · This paper gives a brief overview of the different solar flat plate PV/T technologies, their efficiencies, applications, advantages, limitations and research opportunities available.

Photovoltaic systems

Feb 25, 2016 · The solar panels are only a part of a complete PV solar system. Solar modules are the heart of the system and are usually called the power generators. One must have also

Fab & photovoltaic modules: failure rates and

May 21, 2024 · Safety testing of flat-plate modules (IEC 61730, ANSI/UL 1703) Evaluation of polymeric components used in PV modules Reliability research to predict lifetime of modules

Thermal Characteristics of Flat-Plate Photovoltaic

Aug 8, 2013 · The thermal characteristics of flat-plate photovoltaic modules, deployed at fixed tilt, are investigated in order to characterize their behavior against meteorological elements.

Literature Review on Flat Plate Photovoltaic-Thermal

Aug 9, 2021 · The purpose of this review is to provide the detailed theoretical study, design components of PVT solar collector module, a broad classification of various emerging

Experimental & numerical investigation and optimization on a novel flat

Jul 15, 2021 · Experimental & numerical investigation and optimization on a novel flat-plate PV/T system using CdfTe thin-film solar modules of sandwich structure

Systematic Review of Flat Plate Photovoltaic Thermal

The use of hybrid solar panels represents a promising technology for the simultaneous generation of electrical and thermal energy from solar radiation. However, their implementation has been

Ground Mount Structure Installation Manual

May 20, 2025 · System Certification The Solar Foundations Ground Mount Structure (Rack Mounting System) conforms to UL 2703 Standard for Safety First Edition: Mounting Systems,

Structures for photovoltaic solar panels

Apr 25, 2024 · "V" type structures are designed specifically for flat surfaces, such as land or terraces. These structures allow easy and efficient installation of

Up‐to‐Date Review on Flat‐Plate Solar Hybrid

Jun 13, 2025 · Photovoltaic (PV) technology is generally perceived as well-developed but suffers a drop in performance at high temperatures. Faced with

Solar photovoltaic thermal (PVT) module technologies

Jan 1, 2020 · A flat-plate PVT (FP-PVT) module usually consists of a flat absorber sheet beneath the PV module, which can include a cover glass to form a glazed type while unglazed types

Thermal Characteristics of Flat-Plate Photovoltaic

Aug 8, 2013 · ABSTRACT The thermal characteristics of flat-plate photovoltaic modules, deployed at fixed tilt, are investigated in order to characterize their behavior against meteorological

flat plate solar photovoltaic module

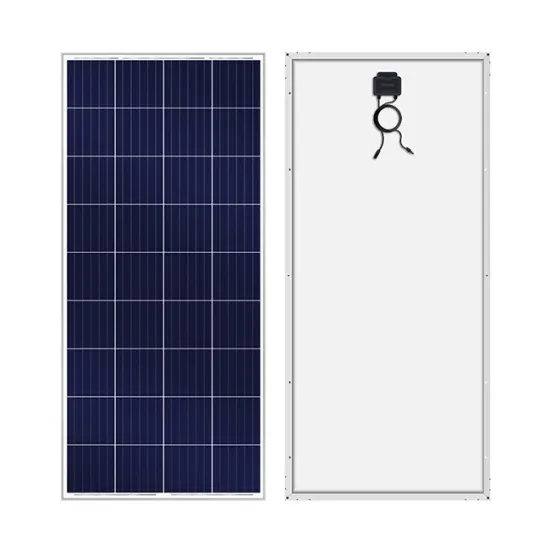

Dec 24, 2023 · One typical flat-plate module design uses a substrate of metal, glass, or plastic to provide structural support in the back; an encapsulant material to protect the cells; and a

Recent progress on flat plate solar collectors and photovoltaic systems

Apr 15, 2021 · The current review presents empirical and numerical analyses of thermal performance development in flat plate solar collectors (FPSCs). Generally, the productivity of

Flat plate solar photovoltaic–thermal (PV/T) systems: A

Nov 1, 2015 · This paper gives a brief overview of the different solar flat plate PV/T technologies, their efficiencies, applications, advantages, limitations and research opportunities available.

Systematic Review of Flat Plate Photovoltaic Thermal

Aug 3, 2025 · The concept of integrating a PV module with a solar thermal collector (STC) emerged in the 1970s,[13 –15] leading to the devel-opment of photovoltaic thermal (PVT) panels.

Flat-plate solar power plant

The flat plate solar collector is a type of thermal solar panel whose purpose is to transform solar radiation into thermal energy. This type of solar thermal panels have a good cost/effectiveness

Flat Plate Photovoltaic/Thermal System

2.3.1 Flat-plate vs. concentrator photovoltaic thermal collectors Photovoltaic thermal (PVT) collectors are mostly used in flat plate configuration for their simplicity in design and

BALLASTED ROOF SOLAR PV MOUNTING SYSTEM

Jul 3, 2024 · Overview Ballasted-single Side Solar Pv Mounting System is a non-penetration solution for flat rooftop, to meet di erent tilt angles installation. It is applicable to the roof areas

Concentrated Photovoltaics

Sep 25, 2018 · Unlike the flat-plate photovoltaic systems seen on roofs, solar concentrators must track the sun to focus light on to a solar cell throughout the day. Sun tracking increases the

Systematic Review of Flat Plate Photovoltaic Thermal

Jul 28, 2025 · This section describes the main components commonly used in at plate PVT systems, as shown in Figure 3:[17,39,44,45] 1) trans-fl parent cover (optional); 2) solar PV

Development and applications of photovoltaic–thermal systems

Mar 1, 2019 · Thus, the overall efficiency of the photovoltaic–thermal (PV/T) system can increase accordingly. In this work, we attempt to summarize various research works on technologies

Energy Sector Technology factsheets Utility-scale Solar

Jul 14, 2022 · , the latter being deployed more widely, globally (Green, 1993; Kelly, 1993). Essentially, flat-plate systems are built around monocrystalline or polycrystalline solar cells65

Solar Photovoltaic Modules'' Performance Reliability and

Aug 16, 2025 · Historically, when PV solar power was initially developed at the Flat-Plate Solar Array Block Program in the 1970s, the goal was to provide a sustainable energy alternative.

Literature Review on Flat Plate Photovoltaic-Thermal

Aug 9, 2021 · FLAT PLATE PHOTOVOLTAIC THERMAL (PV/T) SOLAR COLLECTOR: DESIGN OVERVIEW The flat plate photovoltaic thermal solar collector consists of different component

Systematic Review of Flat Plate Photovoltaic Thermal

Jul 28, 2025 · The concept of integrating a PV module with a solar thermal collector (STC) emerged in the 1970s,[13 –15] leading to the devel-opment of photovoltaic thermal (PVT) panels.

Flat solar collectors: parts and types of collectors

May 30, 2018 · The flat plate solar collector is a type of thermal solar panel whose purpose is to transform solar radiation into thermal energy. This type of solar

6 FAQs about [Structure of flat-plate solar photovoltaic modules]

What is a flat plate solar PV/T system?

Fig. 2. A flat plate solar PV/T system with same sized separate flat plate SWH and solar PV module. Installing photovoltaic (PV) modules can use only 10% to 15% of the incident solar energy, and they reduce the possibility of using solar thermal collectors in the limited roof-space of buildings .

What is flat plate photovoltaic (PV)?

What is Flat Plate Photovoltaic (PV): It is the most popular type of solar array design module that only contains flat solar panels.

How does a flat plate photovoltaic work?

A flat plate collector (FPC) relies on thermal energy transfer to operate. The working medium of the Flat plate Photovoltaic (PV) exchanges the energy from the sun’s rays. The collector’s heat-absorbing plate takes in direct sunlight. Some of the energy from the sun’s beams is converted into heat as it strikes the flat plate surface.

How does a flat plate solar collector work?

The working medium of the Flat plate Photovoltaic (PV) exchanges the energy from the sun’s rays. The collector’s heat-absorbing plate takes in direct sunlight. Some of the energy from the sun’s beams is converted into heat as it strikes the flat plate surface. The flat-plate solar collector’s temperature increases as a result.

What are the different types of photovoltaic modules?

Three main types of photovoltaic module design have shown particular promise in both performance and cost. These are the crystalline flat plate, the thin-film flat plate and concentrator modules. Currently available commercial flat-plate modules are based on either crystalline silicon or thin-film amorphous silicon cells.

What are the different types of flat plate modules?

Currently available commercial flat plate modules are based on either crystalline silicon or thin film amorphous silicon cells. There are also a number of concentrator installations in different countries based on single crystal silicon cells. Crystalline silicon flat plate modules dominate the power market, defined as arrays larger than 50 Wp.

Learn More

- PVDF film for solar photovoltaic modules

- Sources of solar photovoltaic modules in Maputo

- Ultra-white solar glass photovoltaic modules

- The internal structure of a solar photovoltaic panel

- Accra rural household solar photovoltaic modules

- How many watts does a photovoltaic solar panel have

- 3 kilowatt solar photovoltaic panel

- Thickening of solar photovoltaic panels

- Botswana rooftop solar photovoltaic panels

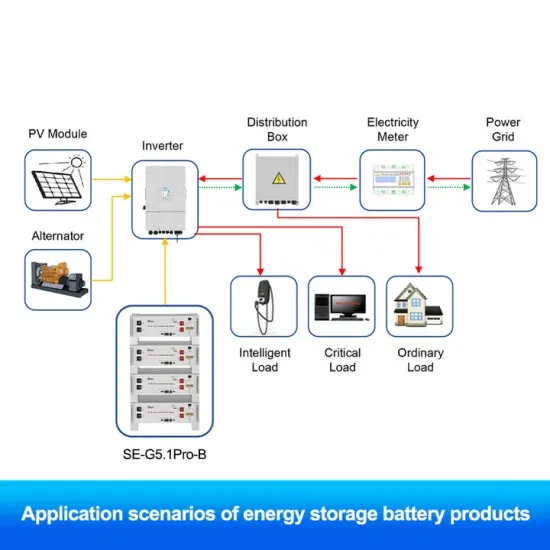

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.