The Difference Between Single Glass and Double Glass Solar

Oct 2, 2024 · In the ever-evolving world of solar energy, choosing the right type of solar module can feel like navigating through a maze. Among the myriad of options, two types stand out:

Differences between double-glass photovoltaic modules

What is the difference between double-glass solar panels and single-sided solar panels? The main difference between double-glass photovoltaic modules and single-sided glass solar

Towards 50 Year Lifetime PV Modules: Double Glass vs. Glass

Mar 29, 2024 · Bifacial modules with double glass architectures have been deployed to capture the rear-side irradiance thereby increasing the light captured. The choice of a double glass

Key Differences Between Half-Cut Modules & Bi

May 17, 2024 · The selection between half-cut modules and bi-facial modules hinges upon factors such as project requisites, site conditions, and budgetary

What are the differences between single-glass

Oct 22, 2020 · Single-glass Solar Module: As the first layer of materials in the solar module structure, tempered glass can effectively protect the panel and

What is the Difference between Single Glass and

Aug 7, 2024 · Discover the key differences between single glass and double glass solar panels. Learn about efficiency, durability, and cost to choose the best for

TRANSPARENT BACKSHEET VS. DUAL GLASS WHITE PAPER

Jul 30, 2023 · TRANSPARENT BACKSHEET VS. DUAL GLASS WHITE PAPER dules (TB) and dual glass bifacial modules (GG). This white paper evaluates advantages and disadvantages

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass

Single Glass Vs Double Glass Solar Panels | Best

May 4, 2025 · Understanding the difference between single glass and double glass solar panels is essential for selecting the right option for your energy

A comprehensive review and outlook of bifacial photovoltaic

Nov 1, 2020 · The glass-glass structure of the bPV modules contributes to a lower cleaning frequency [32] and longer lifetime, than mPV modules that have the traditional glass-organic

JinkoSolar: Transparent backsheet vs dual glass

Mar 10, 2020 · Based on a study of the two types of bifacial products and a long-term outdoor performance test carried out by JinkoSolar, comparisons from multiple perspectives are

Bifacial single glass encapsulation of solar module – An

Jul 1, 2025 · Outdoor performance of PV modules encapsulated with two different approaches showed that annual power generation of single glass solar modules was higher than that of

TRANSPARENT BACKSHEET VS. DUAL GLASS WHITE PAPER

Jul 30, 2023 · VS. DUAL GLASS WHITE PAPER but customers have a choice between transparent backsheet bifacial modules (TB) and dual glass bifacial modules (GG). This white

Comparison of Glass/Glass and Glass/Backsheet PV Modules Using Bifacial

Mar 5, 2015 · Bifacial solar cells can be encapsulated in modules with either a glass/glass or a glass/backsheet structure. A glass/backsheet structure provides additional module current

JA Solar PV Bifacial Double-glass Modules Installation

Jul 18, 2025 · The connection between photovoltaic module and photovoltaic module bracket should be in the form of fixed aluminum alloy press block standard parts, rail groove insertion

What Is the Difference Between Bifacial G2G and Bifacial G2TB?

Bifacial G2G: Offers superior durability due to the double glass construction, making it more resistant to physical damage and environmental wear. Bifacial G2TB: While durable, the

6 FAQs about [Differences between bifacial modules and double-glass modules]

Do bifacial modules come with frames?

As a result, most glass-glass modules come with frames in place. Compared with standard glass backsheet technology, framed modules with two layers of glass are heavier. Therefore, transparent backsheets are a solution for a lighter bifacial module. A more lightweight module means less cost on transportation, labor, and trackers whenever applicable.

Why are glass-glass bifacial modules becoming more popular?

Due to their better reliability, glass-glass bifacial configurations have a larger portion of the worldwide bifacial module market share. Glass shortages, weight concerns for larger format modules, and decreasing prices for transparent backsheets have caused some manufacturers to switch to a glass-transparent backsheet structure.

Does Trina Solar have a dual glass bifacial module?

However, Trina Solar has made such a breakthrough by abandoning the backsheet and developing the brand-new dual glass module. Trina Solar Vertex TSM-DEG21C.20 (670 W) framed dual-glass bifacial module

What is the difference between bifacial and double glazed panels?

The double-glazed design gives them a transparent or translucent appearance, which is different from the opaque single-sided panels. Main difference: The design of single-sided panels is simpler and lighter, while bifacial double-glazed panels are heavier and have a more complex and modern appearance due to the double-glazed structure. 2.

What is bifacial glass technology?

Bifacial glass technology is the preferred material among manufacturers for the rear side cover of the modules. Some key advantages of the glass-glass structure are: Glass-glass modules can also be frameless, which helps eliminate the cost of an extruded aluminum frame. However, glass-glass models with frames have a lower risk of breakage.

What is a dual glass module?

Our dual glass modules use the same internal circuit connection as a traditional glass-backsheet module but feature heat-strengthened glass on both sides. We produce the back glass with a unique drilling technique that ensures the reliability of both the junction box installation and the module.

Learn More

- Differences between bifacial modules and double-glass modules

- Differences between double-glass and single-glass modules

- Actual power of double-glass photovoltaic modules

- Huawei Belgrade double-glass photovoltaic modules

- Double-glass bifacial module installation

- Huawei St George PV bifacial modules

- Vienna double-glass photovoltaic modules

- Multicrystalline double-glass photovoltaic modules

- Monocrystalline single-sided and bifacial photovoltaic modules

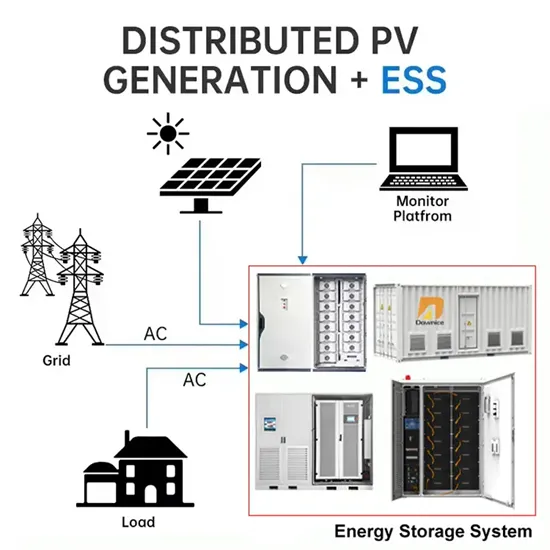

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.