Inverter design using high frequency

Feb 27, 2021 · In which we are developing an inverter which is to be light in weight, compact and highly energy efficient. This can possible with the help of High Frequency Inverter; hence we

A High-Frequency Inverter for Variable-Load Operation

Jan 18, 2019 · This paper presents a new inverter architecture suitable for driving widely varying load impedances at high frequency (HF, 3-30 MHz) and above. We present the underlying

Understanding Frequency Inverters: A Comprehensive Guide

Feb 23, 2025 · Low-Frequency Inverter: An Overview A low-frequency inverter operates at a lower switching frequency, typically below 60 Hz. It is designed for applications requiring high power

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · A high-frequency filter that is connected to the power supply side or load side of an inverter to absorb noise that is generated in an inverter when a power device switches.

High-Frequency Variable Load Inverter Architecture

Jun 4, 2025 · The invented high-frequency inverter system enables HF power delivery directly into highly variable impedance loads with a relatively high efficiency. A pair of inverters are coupled

Review of very high frequency power converters

Jul 1, 2020 · The matching networks are added between the inverter stages and rectifier stages to adjust the equivalent impedance of the rectifier stage. Fig. 4

Eastwood TIG 200 AC/DC INVERTER WELDER 240 Volt / 200

With High Frequency Inverter Technology. 110 Volts - 240 Volts. 10 Amp - 200 Amp. Comes with everything in the pictures, and everything in the pictures is BRAND NEW, NEVER USED.

High Frequency Inverter vs low Frequency Inverter

Conclusion In conclusion, the choice between high-frequency and low-frequency inverters depends largely on the specific needs of the application. High-frequency inverters offer the

A New Architecture for High-Frequency Variable-Load

Dec 4, 2023 · CONCLUSION This paper introduces an inverter architecture and associated control approach for providing efficient delivery of high-frequency power into variable load

High-Frequency Inverters: From Photovoltaic, Wind, and

Jul 26, 2022 · dc–ac converter 29 High-Frequency Inverters, the HF transformer is incorporated into the integrated structure. In the subsequent sections, based on HF architectures, we

High-frequency inverter (US version)-Dongguan Lithium

Dongguan Lithium Valley Energy Co., Ltd. is a subsidiary of Zongshen Group (stock code: 001696). Established in 2013, it is a national high-tech enterprise specializing in energy

High-Frequency vs. Low-Frequency Inverters

High-Frequency Inverters: High-frequency inverters can handle moderate surges, but their surge capacity is generally lower than low-frequency inverters. They may struggle to run devices with

High Gain DC–AC High-Frequency Link Inverter With Improved

Feb 25, 2021 · This article presents a high gain pure sine- wave inverter based on the full-bridge dc–ac high-frequency link cycloconverter topology for telecom or general-purpose

High Frequency Power Inverters: A Guide To Modern Solutions

May 4, 2024 · High frequency power inverters have revolutionized the field of electrical conversion, enabling efficient and reliable power supply solutions for various applications. In

6 FAQs about [Berne high frequency inverter]

What is a high frequency variable load inverter architecture?

This thesis presents a high frequency variable load inverter architecture along with a physical prototype and e ciency optimizing controller. The inverter architecture consists of two constituent inverters, one connected directly through the load and the other connected through an immittance converter, which acts as a lossless power combiner.

Can inverters provide efficient delivery of high-frequency power into variable load impedances?

VI. CONCLUSION This paper introduces an inverter architecture and associated control approach for providing efficient delivery of high-frequency power into variable load impedances while maintaining resistive/inductive loading of the constituent inverters for ZVS soft switching.

Can a high-frequency variable load inverter directly drive widely variable loads?

Typically a tunable matching network is used to transform the varying load into a ciency and impairing transient response. This thesis presents the design, physical prototype, controller, and experimental results of a high-frequency variable load inverter architecture (referred to as HFVLI) that can directly drive widely variable loads.

What is a high frequency inverter?

I. INTRODUCTION Many applications – ranging from industrial plasma generation to wireless power transfer – require inverters (or power amplifiers) that can deliver power at high frequency (HF, 3-30 MHz).

Can hfvli drive a wide load range RF inverter?

From these results it is evident that the HFVLI prototype is successful in the goal of driving a wide load range at high power power levels. rst physical prototype of of a wide load range RF inverter based on the proposed high frequency variable-load inverter topology was designed and built along with an e ciency optimizing controller.

What is HF variable load inverter architecture?

II. THE HF VARIABLE-LOAD INVERTER ARCHITECTURE The proposed architecture, illustrated in Fig. 1, comprises two inverters, with one directly coupled to the load and the other coupled to the load via an immittance converter .

Learn More

- Freetown High Frequency Inverter

- Belgian electromagnetic wave high frequency inverter

- High frequency inverter sine wave

- Burkina Faso high frequency inverter 12v to 220v

- High power industrial frequency inverter

- Is the EK inverter a high frequency machine

- High frequency chopper inverter

- The difference between inverter and high frequency power generation

- How much is the price of high frequency inverter in Ho Chi Minh Vietnam

Industrial & Commercial Energy Storage Market Growth

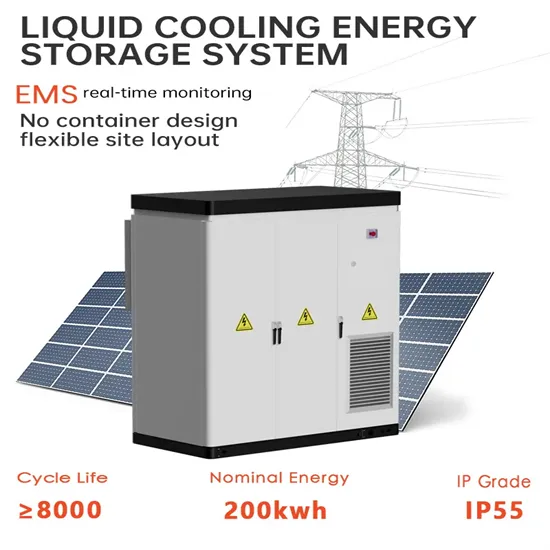

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

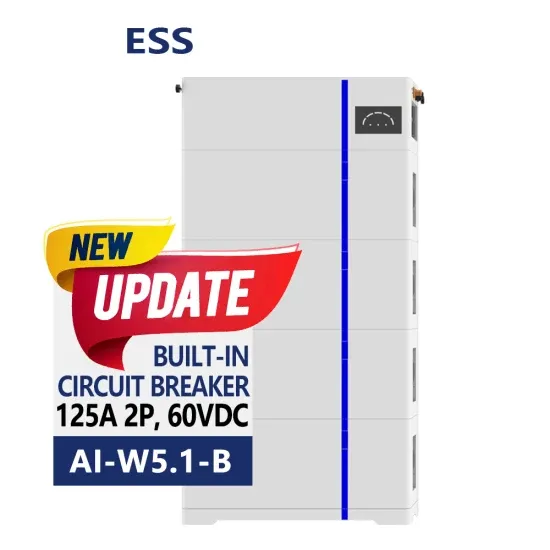

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.