A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · The requirements for the grid-connected inverter include; low total harmonic distortion of the currents injected into the grid, maximum power point tracking, high efficiency,

A Single-Stage High-Frequency-Link Split-Phase

Jan 1, 2024 · Abstract High-frequency-link (HFL) inverters have drawn a lot of attention, owing to their high transformer utilization factor, bidirectional energy transfer, and easy implementation

Differential Buck DC–DC Chopper Mode Inverters With

Abstract—A circuit configuration and a circuit topological fam-ily of differential buck dc–dc chopper mode inverter with high-frequency link are proposed in this paper.

Phase Shifted Soft Switching High Frequency Converter

Nov 30, 2020 · ABSTRACT: This paper deals with the suitable topologies for consumer induction heating systems. This system consists of soft switching chopper based boost pfc converter

Phase Shifted Soft Switching High Frequency Converter

Nov 30, 2020 · ollowing high frequency inverter stage with IH load is descri ed as simple resistance RS. The circuit operation in each operating mode is simply descri t only flows to

SINGLE-STAGE MULTI-INPUT FORWARD DC-DC CHOPPER TYPE HIGH-FREQUENCY

A single-stage multi-input forward DC-DC chopper type high-frequency link''s inverter with series simultaneous power supply includes a multi-input single-output combined isolated bidirectional

Chopper Transformer Problem (High Freq. Inverter)

Sep 25, 2022 · as you surely know, on high frequency inverter, at first I step up the voltage from 12VDC or 24VDC to 311VDC then I do the SPWM Switching to generate the pure sine wave, I

High frequency PWM boost chopper-fed DC-DC converters

High frequency PWM boost chopper-fed DC-DC converters with coupled-inductors VIII IEEE International Power Electronics Congress, 2002. Technical Proceedings. CIEP 2002.

Differential buck DCDC chopper mode inverters with high-frequency

These two choppers generate unipolarity sinusoidal pulse width modulation voltage waveforms with positive and negative half low-frequency cycle separately. Each dcdc chopper consists of

Differential decompression DC chopper type high-frequency chain inverter

A DC chopper and inverter technology, applied in the direction of DC power input conversion to DC power output, AC power input conversion to DC power output, instruments, etc., can solve

High frequency inverter from egs002

Oct 7, 2017 · Hi, I have 1500watt chinese inverter that is based on high frequency chopper transformer. Its square wave. I was thinking of making a pure sinewave out of it using egs002

Simulation of High Frequency Step Down of Single Phase

Aug 7, 2023 · Abstract This paper presents the concept of single phase matrix converter as an universal converter for high frequency step down operation. Matrix converter implemented as

Voltage and Harmonic Control of Inverters

This scheme has the advantage of good power factor at the ac input of the bridge rectifier and a faster voltage response owing to a smaller time-constant of the LC-filter on the output side of a

Differential Buck DC–DC Chopper Mode Inverters With

Each dc–dc chopper consists of high frequency inverter, high frequency transformer, and high frequency rectifier. The circuit topological family includes six cir-cuit topologies,...

A High-Frequency-Link Split-Phase Voltage-Source

Apr 14, 2025 · This article proposes a novel single-stage high-frequency-link split-phase microinverter that utilizes dual buck–boost ac choppers to form a secondary-side

What is the difference between chopper and inverter?

What is the principle of chopper What is the function of inverter chopper in SMPS? In general, an SMPS initially converts the ac source voltage into a dc voltage through a rectifier and an input

A full bridge buck DC chopper type multi-input inverter | IET

Jul 5, 2022 · A full bridge buck DC chopper type multi-input inverter is proposed in this article with the merits of single-stage power conversion, high-frequency electrical isolation and wide duty

High Frequency Inverter with a Boost Chopper | Request PDF

Jan 1, 2010 · A high-frequency inverter is proposed and designed for high-power induction heating applications. It consists of a boost chopper, half bridge, and series load resonant circuit.

Combined Bidirectional Buck–Boost DC–DC Chopper-Mode Inverters

Oct 1, 2013 · Abstract: A circuit configuration, a circuit topological family, a buck-mode active clamped circuit, and an instantaneous output voltage feedback control strategy of combined

Pure sine wave inverter with high-frequency chopper current

A current sampling and pure sine wave technology, applied in the field of pure sine wave inverters, can solve problems such as inconvenient sampling and detection, and achieve the

Differential decompression DC chopper type high-frequency chain inverter

A DC chopper and inverter technology, which is applied in the direction of converting DC power input to DC power output, AC power input converting to DC power output, instruments, etc.,

High frequency inverter including a boost chopper | Request

Jan 1, 2009 · Request PDF | High frequency inverter including a boost chopper | This paper presents a new high frequency inverter for high power induction heating applications under a

Learn More

- How much is the price of high frequency inverter in Ho Chi Minh Vietnam

- Macedonia high frequency inverter equipment

- Assembly of high power industrial frequency inverter

- High frequency inverter has low frequency

- Niamey high frequency power inverter

- New generation of intelligent industrial frequency high power inverter

- High frequency resonant inverter

- Inverter high voltage main frequency or low voltage mixed frequency

- High frequency machine to inverter

Industrial & Commercial Energy Storage Market Growth

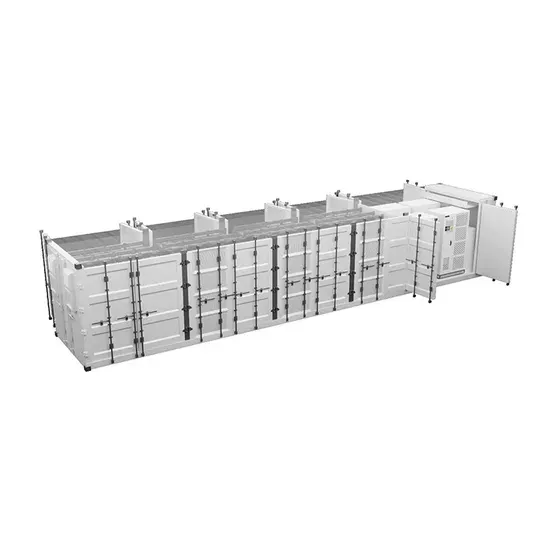

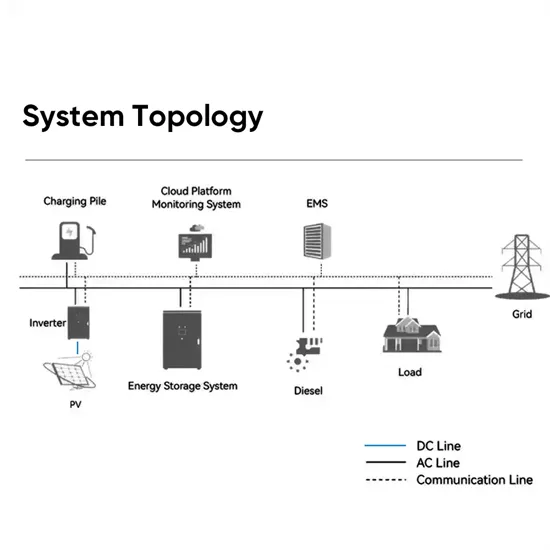

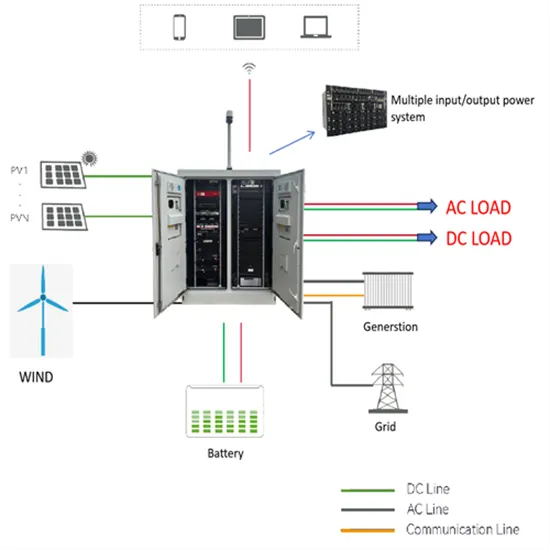

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.