Simple Sinewave Inverter Circuits – Making Easy

Jul 13, 2021 · The following is a high efficiency sine wave inverter electrical diagram, the circuit with 12V battery-powered. First with a double voltage

Pure Sine Wave Inverter: All You Need to Know

May 10, 2023 · This is where pure sine wave inverter, also known as true sine wave inverter, comes into play. They are advanced power conversion devices that produce a high-quality AC

high-frequency power inverter: high-frequency sine wave inverter

Jul 20, 2020 · The high-frequency power inverter uses a low-frequency sine wave in combination with a high-frequency DC signal so that when one is combined with the other, the two waves

High Frequency 2500W Pure Sine Wave Inverter

Jun 3, 2025 · High frequency inverters have higher inverter conversion efficiency, lighter weight, and smaller size, making them portable and suitable for use in

High Gain DC–AC High-Frequency Link Inverter With Improved

Feb 25, 2021 · This article presents a high gain pure sine- wave inverter based on the full-bridge dc–ac high-frequency link cycloconverter topology for telecom or general-purpose

High-Frequency Inverters: From Photovoltaic, Wind, and

Jul 26, 2022 · dc–ac converter 29 High-Frequency Inverters, the HF transformer is incorporated into the integrated structure. In the subsequent sections, based on HF architectures, we

Power Frequency Inverter vs. High Frequency

May 15, 2024 · In the field of power electronics and energy conversion, inverters, as key equipment for power conversion, play a vital role. Inverters are capable

A Novel Series Resonant High-Frequency Link Sine-wave Inverter

Jun 16, 2005 · The proposed system consists of a full bridge LC series high frequency (HF) inverter which transforms the DC input into a HF sine-wave current source, an isolated HF

High Frequency Inverter vs low Frequency Inverter

Introduction What is a High Frequency Inverter? What is a Low Frequency Inverter? Introduction By the early 1980s, pure sine wave inverters had become more commercially available,

Pros & Cons of High-Efficiency Pure Sine Wave Inverter

Dec 4, 2024 · High-frequency pure sine wave inverters may involve intricate circuitry, potentially leading to more complex maintenance and a higher likelihood of component failure over time.

800VA Pure Sine Wave Inverter''s Reference Design

Jul 30, 2025 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · ABSTRACT The High-Frequency Inverter is mainly used today in uninterruptible power supply systems, AC motor drives, induction heating and renewable energy source

800VA Pure Sine Wave Inverter''s Reference Design (Rev. A)

Apr 1, 2023 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility-supplied

Learn About High vs. Low Frequency Inverters:

Feb 10, 2025 · A low frequency inverter is a classification of inverters that can produce a pure sine wave or a modified sine wave. Q: Which is better, a high

China High Frequency Sine Wave Inverter, High Frequency Sine Wave

China High Frequency Sine Wave Inverter wholesale - Select 2025 high quality High Frequency Sine Wave Inverter products in best price from certified Chinese High Frequency

(PDF) A bidirectional, sinusoidal, high-frequency

Aug 1, 2001 · A new method for the design of a bidirectional inverter based on the sinusoidal pulse-width modulation principle and the use of a low-cost and

High-Frequency, GaN Diode-Free Motor Drive Inverter

Sep 9, 2021 · In contrast to conven-tional motor-drive-outputting, high-voltage PWM power, the GaN inverter generates pure sine wave power with-out a bulky filter. This allows motors to

6 FAQs about [High frequency inverter sine wave]

What is a high frequency inverter?

The high frequency inverter can deliver the same power at higher frequency with a much smaller and lighter transformer, as a result, the HF inverter is often called transformer-less inverter, or TL inverter.

What is the difference between sigineer HF and low-frequency inverters?

The Sigineer low-frequency inverters can output a peak 300% surge power for 20 seconds, while high-frequency inverters can deliver 200% surge power for 5 seconds, check our HF solar power inverters. Low-frequency inverters take power impact through its big transformer which acts like a surge relief for the circuit.

What is the difference between high frequency and low frequency inverters?

Here is the major difference of them: Thanks to the heavy-duty transformer, low frequency inverters have much higher peak power capacity and reliability. The transformer handles higher power spikes with longer duration than high-frequency inverters when it comes to driving inductive loads such as electric motor, pump, compressor, air conditioners.

What is a modified square wave inverter?

The Modified Square Wave also known as the Modified Sine Wave Inverter produces square waves with some dead spots between positive and negative half-cycles at the output. The cleanest utility supply like power source is provided by Pure Sine Wave inverters.

How do high frequency power inverters convert DC to AC?

High frequency power inverters typically convert the DC to AC by driving the transistors at a much higher frequency from 50 Kilo Hz to a few million Hz. Low frequency inverter circuit diagram

What is a low frequency inverter?

Both of the two type of inverters can be built with utility charger or solar charger and be called “inverter charger”. Here is the major difference of them: Thanks to the heavy-duty transformer, low frequency inverters have much higher peak power capacity and reliability.

Learn More

- Caracas high frequency sine wave inverter

- High frequency pure sine wave inverter

- High frequency inverter sine wave

- Island electromagnetic wave high frequency inverter

- Industrial frequency sine wave inverter multifunctional LCD

- Abuja Industrial Frequency Pure Sine Wave Inverter

- Belgian electromagnetic wave high frequency inverter

- Vatican pure sine wave power frequency inverter

- Sine wave inverter frequency adjustment

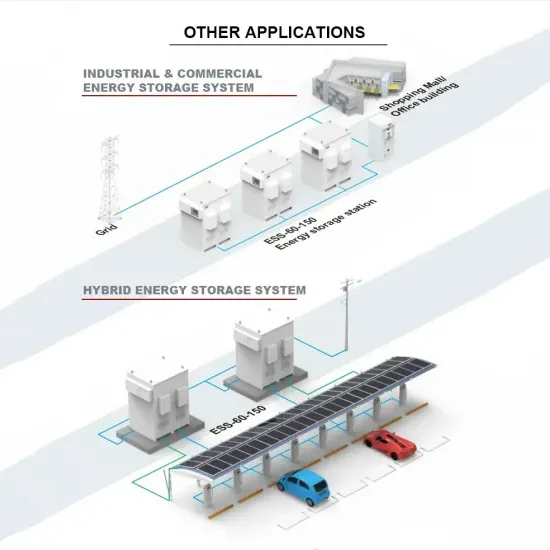

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

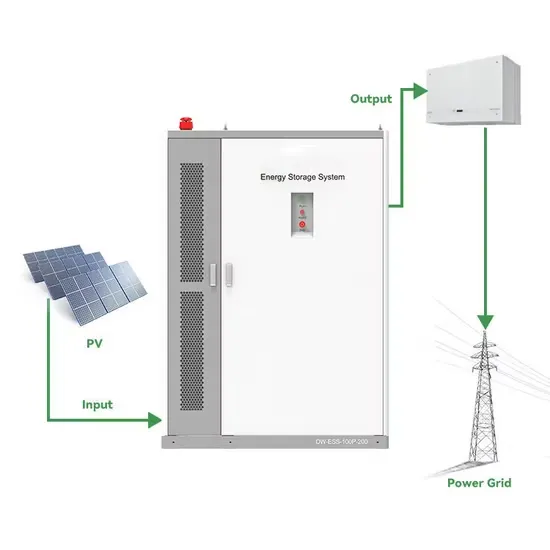

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.